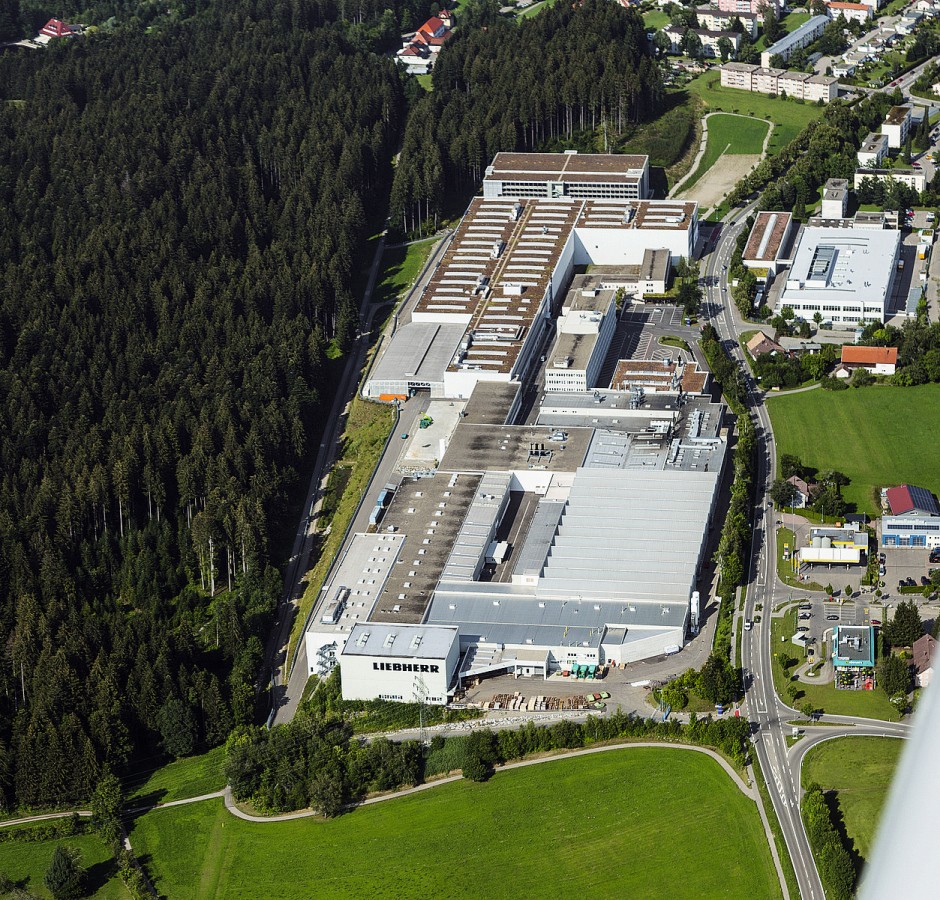

With around 2500 employees, Liebherr-Aerospace Lindenberg GmbH (Lindenberg and Friedrichshafen sites) is part of a family-owned company with around 48,000 employees worldwide.

Hardly any other sector is subject to as many standards and regulations as aviation. At Liebherr-Aerospace Lindenberg GmbH, for example, this is reflected in the fact that there are 200 standards for electroplating and other coating processes alone. In addition, there are more than 300 heat treatment standards and, as if that were not enough, around 1,000 company standards. Things are not exactly simplified by the special treatments of some exotic steel grades and/or the fact that some components have to have up to three different hardness levels due to design/fatigue requirements.

A total of around 6000 people are employed at the Liebherr site in Lindenberg

A total of around 6000 people are employed at the Liebherr site in Lindenberg

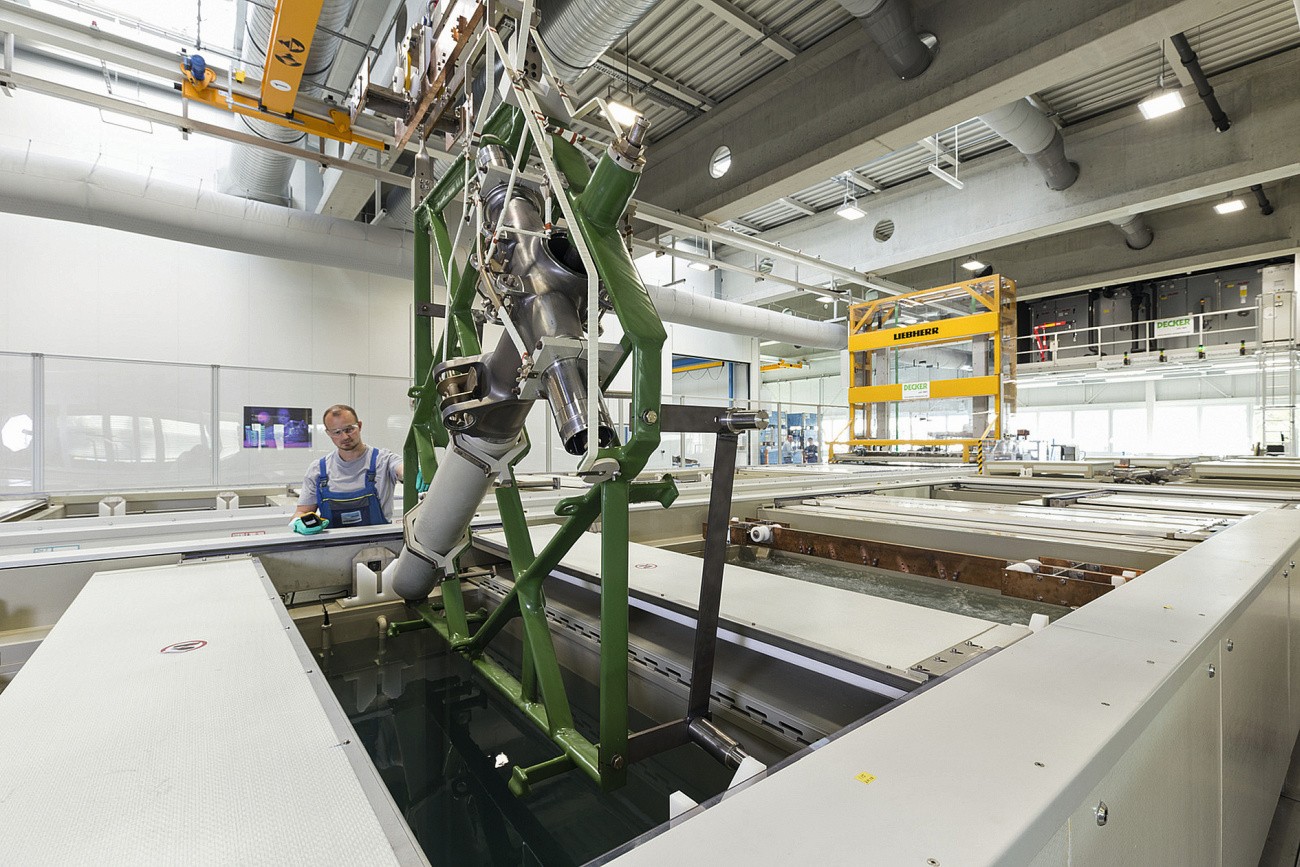

Complicated geometries require sophisticated auxiliary anode management. Fabian Schmied, Head of Cyan Line, explains how the system works But from the beginning: Liebherr-Aerospace Lindenberg GmbH was founded in 1960. It develops, manufactures and supports integrated systems and components for the aviation industry. The landing gear, flight control and actuation systems as well as gearboxes and electronics from the Allgäu region are used in a wide variety of airplanes and helicopters on all continents. Liebherr-Aerospace Lindenberg GmbH is also a major player in the aviation industry thanks to high investments in research and development. In 2019, the company generated a turnover of 757 million euros, and in 2020, the year of the coronavirus pandemic, this figure was still 536 million euros.

Complicated geometries require sophisticated auxiliary anode management. Fabian Schmied, Head of Cyan Line, explains how the system works But from the beginning: Liebherr-Aerospace Lindenberg GmbH was founded in 1960. It develops, manufactures and supports integrated systems and components for the aviation industry. The landing gear, flight control and actuation systems as well as gearboxes and electronics from the Allgäu region are used in a wide variety of airplanes and helicopters on all continents. Liebherr-Aerospace Lindenberg GmbH is also a major player in the aviation industry thanks to high investments in research and development. In 2019, the company generated a turnover of 757 million euros, and in 2020, the year of the coronavirus pandemic, this figure was still 536 million euros.

Nevertheless, the company remained eager to invest. While 20 million euros were invested in new technologies in 2019, this figure was still 13.8 million euros in 2020. This makes Liebherr-Aerospace one of the top ten Airbus suppliers.

The company also has an advantage over its competitors thanks to its high level of vertical integration. Around 70 % of all work and products are made in-house - including software development - and only 30 % are purchased. It is clear that additive manufacturing methods have also been contributing to this ratio for a few years now.

The large electroplating area at the Lindenberg site is fully equipped for the future, both in terms of technology and space. 78 different coating and decoating processes are mastered there. Equipped in this way, the plant also carries out orders from external companies on a contract basis.

As an expert in surface technology, Dr. Klaus Schöttler is involved in many other tasks. The structural improvement of electroplating processes is very close to his heart. He is also involved in water pollution control and immission control as well as being a specialist chemical consultant for fire protection. He describes the comprehensive capabilities of Liebherr-Aerospace Lindenberg GmbH using the example of cadmium: "Cadmium as a material and coating material is only used in the rail, nuclear power and aerospace industries under strict regulations. Here in Lindenberg, we are working intensively on replacement technologies for the aviation industry."

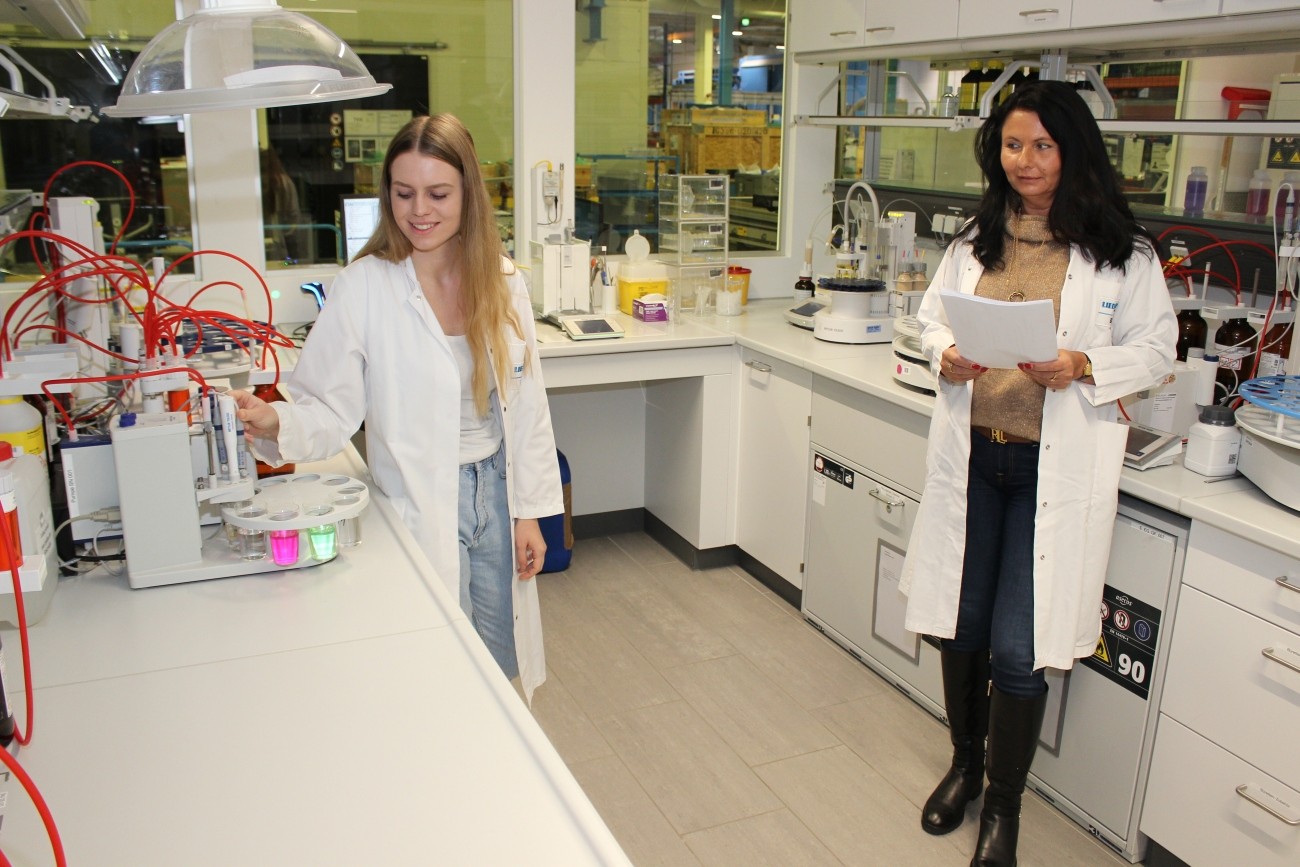

Laboratory manager Katharina Bizu (right) and an employee in their well-equipped 100 square meter area

Laboratory manager Katharina Bizu (right) and an employee in their well-equipped 100 square meter area

Not only the coating department, but also the adjoining laboratory meets all the requirements of a demanding operation. Laboratory manager Katharina Bizu: "When I joined the company 23 years ago, the laboratory was housed in the proverbial broom cupboard. Back then, we had just 15 square meters of space at our disposal. But as the plant grew, so did the demands, the diversification of tasks and the methods required." Today, Katharina Bizu and her colleagues are responsible for routine monitoring of electrolyte parameters, checking the effect of bath contamination on the layers, analyzing the waste water and keeping a record of it, paying attention to the atmospheric environment in the workroom and also checking the properties of supplied products - for example, whether hydraulic oil actually meets the required specification.

The size of the laboratory grew with the requirements

A specialist prepares an aircraft control component for paintingDuringits investigations,thelaboratory also identifies how the chemical products used change during their service life and how long they remain fit for purpose during this process. Bizu is supported in these demanding tasks not only by its employees, but also by the complex diaLIMS laboratory software.

A specialist prepares an aircraft control component for paintingDuringits investigations,thelaboratory also identifies how the chemical products used change during their service life and how long they remain fit for purpose during this process. Bizu is supported in these demanding tasks not only by its employees, but also by the complex diaLIMS laboratory software.

Liebherr-Aerospace is the number 3 landing gear manufacturer on the world market. Its largest customer is Airbus, for example, which equips its A 350 with nose landing gear from the Allgäu. Even the selection of materials and design of a landing gear is like squaring the circle. Dr. Schöttler: "The material must be high-strength without being brittle - and therefore prone to breakage. Its dimensions must be designed to support the aircraft, which weighs several tons, even during hard landings, while at the same time keeping it as light as possible. This is because a high dead weight of the aircraft means less payload and therefore less economic efficiency."

Liebherr obtains the blanks for its landing gear from a drop forge specially approved for aviation. Whenever such a blank is delivered, a series of complicated processes begins. The metal block, which only roughly resembles an aircraft landing gear, arrives in a comparatively soft material state. In line with the principle that trust is good, but control is better, the composition of the blank is checked and compared with the legal requirements and the order. The expert speaks of "sparking off".

The blank is then first machined into its rough shape. It is later brought to medium hardness in the hardening shop before further contours are cut out. This is followed by an initial dimensional check and another inspection of the material for cracks and grinding burn. Finally, the component is finally hardened and tempered. The chassis is given its final shape in the fine machining department before (you guessed it) being put through its paces once again.

A corset with a pre-installed system of auxiliary anodes supports the electroplater during hard chrome plating. Here, the finished part is already freed from the corset After all these work steps, the component is sent to the plant's coating department. There it is first cleaned. This is followed by a compaction process using shot blasting. This eliminates all residual stresses from the high-strength steel and increases its fatigue strength. Another cleaning cycle; activation with high-grade corundum. From now on, the component must no longer be touched and it must be done quickly. The first layer must be applied within a maximum time window of two hours; this can be the aforementioned cadmium, for example. Once this base layer has been applied, the component is placed in a heating chamber for a maximum of three hours, where it remains at 190 °C for 23 hours. It is then chromated, rinsed and dried. Quality assurance measures the coating thickness and other quality-relevant parameters.

A corset with a pre-installed system of auxiliary anodes supports the electroplater during hard chrome plating. Here, the finished part is already freed from the corset After all these work steps, the component is sent to the plant's coating department. There it is first cleaned. This is followed by a compaction process using shot blasting. This eliminates all residual stresses from the high-strength steel and increases its fatigue strength. Another cleaning cycle; activation with high-grade corundum. From now on, the component must no longer be touched and it must be done quickly. The first layer must be applied within a maximum time window of two hours; this can be the aforementioned cadmium, for example. Once this base layer has been applied, the component is placed in a heating chamber for a maximum of three hours, where it remains at 190 °C for 23 hours. It is then chromated, rinsed and dried. Quality assurance measures the coating thickness and other quality-relevant parameters.

If everything is perfect, the bushes are pressed in. These are made from a special bronze. Finally, the chassis ends up in the paint shop. Another layer of cadmium is primed, then the part is left to dry. After any mechanical work, the final coat of paint is applied, the special feature of which is that the final coat, i.e. the top layer, must be impact-resistant. This means that parts hitting the landing gear during take-off and landing (e.g. pebbles on the runway) must not cause any flaking. The headlights and electrical installations are fitted in the final stages.

Airlines pass on their business risk

Klaus Schöttler: "We process new orders and aircraft parts that come to us for maintenance work." Because parts that are installed in aircraft have to meet special quality requirements in terms of materials and production and therefore naturally come at a price, the industry is under high financial pressure. This has led aircraft manufacturers to introduce risk sharing: Whereas a certain quota of components used to be ordered and paid for, today only the components that are actually called up are paid for.

The new chemicals legislation is creating additional pressure. In aviation, for example, the tried and tested cadmium and the use of chromium (VI) coatings are also up for discussion. Liebherr is working on replacing cadmium with zinc-nickel (in series production for five years) and chromium(VI) coatings are being replaced wherever possible by coatings applied using the High Velocity Oxygen Fuel (HVOF) process. This process originates from the aerospace industry, has been known for 40 years and is used at Liebherr in a modified form without a license.

View of the electroplating shop. The tanks must be large

View of the electroplating shop. The tanks must be large

Dr. Schöttler had already introduced an environmental and energy management system in the company in 2007, but the increasingly stringent legal requirements also demanded constant internal adjustments. In 2017, a staff unit for environmental protection and occupational safety was set up, which is now headed up by Pius Maier: "The products we manufacture are subject to internationally applicable aviation standards. However, the production itself must be carried out in accordance with our country's occupational health and safety regulations. As you can imagine, this is sometimes a challenge for us," he smiles. And gives a few examples. For example, aircraft parts that have become unusable are not only disposed of, but destroyed beforehand in order to prevent their unauthorized reuse. At Liebherr, there is also no warehouse where used or critical materials are temporarily stored until they are collected. Certified companies collect them directly. In the case of the Lindenberg site, these must be Bavarian waste disposal companies. Incidentally, this applies to every federal state.

The recovery in aviation will boost Liebherr

Everyone at Liebherr in Lindenberg is now hoping for a rapid economic recovery. Newly won travel freedoms will lead the ailing aviation industry back onto the wings of success - and thus also Liebherr-Aerospace Lindenberg GmbH. Klaus Schöttler is delighted: "When the airlines take off again, we will definitely be on board."

INFO

Liebherr at a glance

The company's success goes back to Hans Liebherr, who, together with designers and craftsmen, invented and built the mobile tower crane in 1949. Germany, which was being rebuilt after the Second World War, was a large market for construction machinery and so production of gearboxes and gears began in 1952 and in 1954 Liebherr presented a lightweight, powerful hydraulic excavator. That year also saw the start of production of refrigerators and freezers. The company has been active in aviation in Lindenberg since 1960.

Today, the Liebherr Group employs around 48,000 people in over 140 companies on all continents. In 2020, it generated a consolidated total turnover of over 10.3 billion euros.