Climate neutrality and sustainability are the issues that will challenge us in the coming years. In 2019, Ursula von der Leyen presented the 10 goals of the Green Deal, which aims to make Europe the first continent to achieve climate neutrality by 2050. A field report.

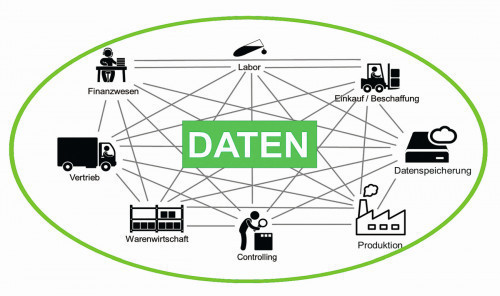

Two of these ten goals are a priority for the industry and should be implemented as soon as possible, not least due to ongoing climate change. These are the topics ofCO2 neutrality and the circular economy (see Fig. 1). Their implementation requires extensive data material that can be collected, evaluated and used for these and other topics with the help of digitalization.

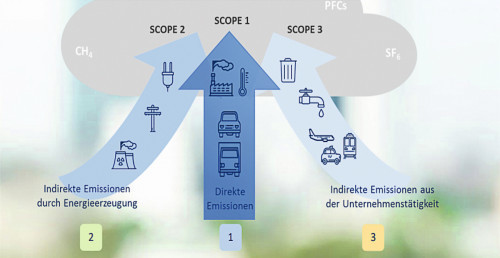

TheCO2 footprint is a prerequisite for achievingCO2 neutrality. It is divided into three areas (see Fig. 2), which are also referred to as Scope 1, 2 and 3 in the literature. The direct emissions (Scope 1) are generated from fossil fuels, e.g. for the production of heat or by driving the company vehicle. Indirect emissions (Scope 2) come from energy sources such as electricity or district heating, the generation of which has already producedCO2. Other indirectsources of CO2(Scope 3) come from production activities, transportation of products and raw materials, not forgetting employees' journeys to work. Free programs are available on the Internet for creating aCO2 footprint. The energy consultant will create a more comprehensive and preciseCO2 footprint, which can be carried out in accordance with DIN EN ISO 140641 on request. A data collection, e.g. over 3 years, can generally be taken from the accounts. The existing programs work and evaluate differently, so that the results are not comparable with each other.

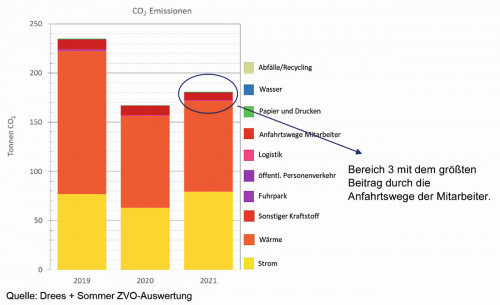

In the spring of this year, some member companies responded to the ZVO call to create an industry-widecarbon footprint over the years 2019-2021, with the option of an individual evaluation for the participating companies. The graph shown in Figure 3 is the result of this evaluation, exemplified by Lohngalvanik Moosbach & Kanne GmbH. As expected, the main share ofCO2 emissions comes from electricity and heat (Scope 1+2). Scope 3 is largely made up of employees' commutes.

Opportunities to reduce emissions through technical innovations

While we can look back on normal business operations in 2019, business activities had to be scaled back in the following year due to the coronavirus-related lockdown, which is reflected in the emissions figures. Business operations normalized in 2021, but emissions did not rise to the level of 2019. This is due to the installation of PV systems. Energy andCO2 savings have been a focus at Lohngalvanik Moosbach & Kanne since 2015. Overall, technical changes (LED lighting, rectifier replacement, roof and window insulation, heat recovery from exhaust air and the commissioning of a combined heat and power plant) have reducedCO2 emissions by a total of 205 tons per year from 2015-2021. If the primary goal of climate neutrality is to be pursued further, levers forreducing CO2 emissions must be found.

These measures were implemented as part of necessary building and plant renovations and more effective use of the energy sources used.

Reduction of theCO2 footprint through digitalized process data

FurtherCO2 reductions could be achieved, for example, by replacing intact but less efficient systems and using green electricity to generate heat. The generation of "green electricity" from solar energy is not sufficient in our latitudes and other sources (wind power) cannot be used at every location. What levers can be found to achieve the primary goal of climate neutrality in the foreseeable future?

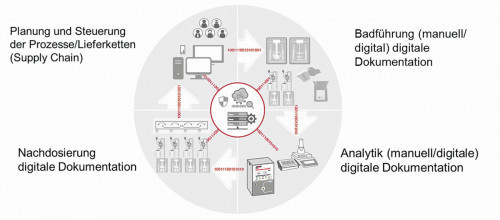

Fig. 4: Digitalization to find the levers

Fig. 4: Digitalization to find the levers

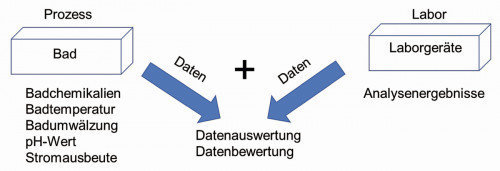

The focus is on potential savings through changes in behavior and working habits that are cost-neutral, e.g. heating and travel habits and the consolidation of production and logistics processes. Technical changes are associated with costs, for example Roof, façade and window insulation, PV systems, heat exchangers, energy storage, tub and pipe insulation, lighting, e-mobility, process conversion. Data from the different areas of work is first required in order to use these adjusting screws sensibly (see Fig. 4). If this data is digitized, evaluated and assessed, the result is

- Stable processes with greater process reliability

- Reduction of chemical consumption in the process and wastewater treatment

- a smallerCO2 footprint.

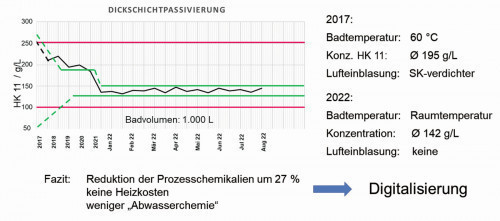

Fig. 5: Process stabilization and optimization using the example of thick-film passivation

Fig. 5: Process stabilization and optimization using the example of thick-film passivation

For example, the bath management of a thick-film passivation process was monitored over five years and the data recorded over the course of the process (see Fig. 5). With the help of digital recording and evaluation of the process data, it was initially possible to reduce the intervention area and then lower the process temperature, adjust the air injection and finally reduce the process and waste water chemicals by 27 %. Lowering the process temperature by 40 °C from 60 °C to room temperature saves thermal energy and thereforeCO2. Heating 1 m³ of water from 20 °C to 60 °C requires 58 kWh, which corresponds to a gas volume of 5.4m3 withCO2 emissions of 12.5 kg. TheCO2 equivalents of the energy sources electricity, crude oil and natural gas are compared inTable 1.

|

Energy source |

Amount |

Energy |

CO2 equivalents |

|

Electricity |

10 kWh |

10.0 kWh |

4.0 kg |

|

Heating oil |

1 l |

12.5 kWh |

3.09 kg |

|

Natural gas |

1m3 |

10.8 kWh |

2.31 kg |

Sustainability with the help of electroplated layers

When looking at electroplated layers, requirements with regard to the circular economy are already fulfilled. They contribute to the sustainability of a product by

- extending the service life

- optimizing corrosion protection

- improving durability in use

- protecting against environmental influences.

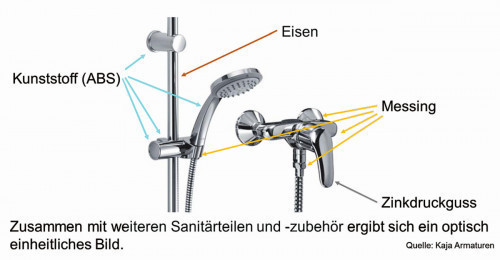

Furthermore, electroplating technology enables an economically sensible choice of base materials for the components of a product, which appears uniform thanks to the electroplated coatings. The sanitary shower fitting shown in Figure 6 consists of four different base materials, which is not visible to the consumer in the overall picture.

Electroplated metal parts are recyclable and can be returned to the material cycle. In addition, the results of new processes show that electroplated plastics can be broken down into the components plastic and metal and the resulting plastic can be reprocessed into injection-moulded parts. This process is already being used successfully in plastic electroplating plants with the production committee, as shown in the presentations "Circular economy through the use of recyclates in electroplated plastics" by Dr. Felix A. Heinzler, BIA Kunststoff- und Galvanotechnik GmbH & Co. KG, and "Recycling of metallized plastics through high-energy impulse treatment" by David Zapf from Hansgrohe SE at the Surface Days in Leipzig this year. Although electroplated surfaces are produced with a high energy input, the sustainability benefits listed here stand in contrast to this in the overall CO2 balance.

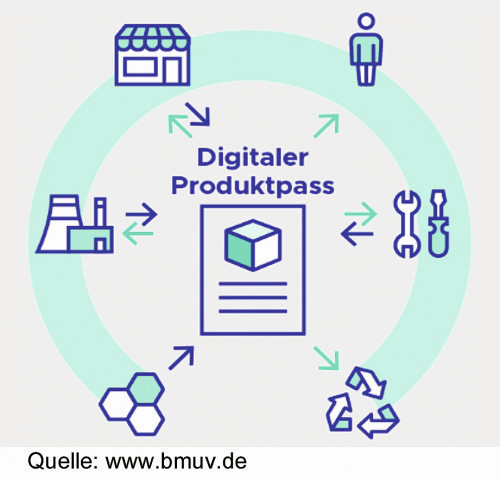

Fig. 7: The digital product passport

Fig. 7: The digital product passport

In order to provide consumers with information on the greenhouse gases generated during production and details on sustainability and recycling options, the EU launched the idea of the product passport (Fig. 7). As shown in Figure 8, every company activity generates large amounts of data in internal and external areas that should be stored. The data relevant to the product passport can be extracted through internal networking and processing of the data (see Fig. 9). For the EU, the product passport is a done deal, even if there is currently no fixed date for it. The recommendation to every manufacturer is therefore to digitize, evaluate and catalog all product and production-specific data internally.

Research on the internet shows that the few product passports that currently exist do not meet EU requirements. However, precise guidelines are still lacking. It is clear that complex supply chains, which include electroplating plants as a link or intermediate link, should be included in the development of guidelines for product passports in order to minimize the effort and make the result as comprehensive as necessary. Trade associations, such as the ZVO, serve as a link between business and politics.

Green Deal - the challenge for SMEs

With regard to climate neutrality and sustainability, small and medium-sized companies in the surface sector face major challenges that can be overcome if the following conditions are met:

- - the technical possibilities are in place

- - Energy suppliers and grid operators play along

- - Bureaucracy is mastered

- - Applications are processed promptly

- - Subsidies are available

- - Financing is secured

- - Profitability is foreseeable.