Monitoring frequency and power is an important quality assurance tool when cleaning with ultrasound in the 250 to 2,000 kHz range. As Ecoclean has demonstrated in test series, laser-acoustic microphones can also reliably detect sound waves in the high-frequency range up to two MHz. The system manufacturer's new so-called APM (Acoustic Performance Measurement) solution now monitors ultrasonic frequency and power contact-free both in fully automated ultrasonic multi-bath immersion systems and in closed chamber cleaning systems.

The SBS Ecoclean Group develops, produces and sells equipment, systems and services for industrial component cleaning and surface treatment as well as customized automation solutions. High-frequency ultrasound is used when very fine particles and minimal film contamination need to be removed from sensitive or finely structured surfaces. This is the case in semiconductor production, microsystems technology and electronics, precision optics, analysis, laser and vacuum technology and medical technology, for example. In order to reliably achieve the cleanliness requirements defined for perfect functioning and to avoid damaging or impairing the sensitive components, regular checks of the vibration characteristics and the calculation of cleaning-relevant key figures are essential quality parameters. For these applications, Ecoclean has extended the measuring range of the innovative Acoustic Performance Measurement (APM) technology, which was previously used to record ultrasonic frequencies up to 132 kHz inline without contact, to two megahertz on the basis of laser acoustics.

Detection of the frequency spectrum proven by test series

The development of the new APM measuring system was preceded by a series of tests with a laser-acoustic microphone. The tests were carried out in an ultrasonic multi-bath immersion system and with ultrasonic systems with 500 kHz and 1,000 kHz plate transducers. In addition, plate transducers with oscillation frequencies of 40, 80 and 120 kHz already present in the cleaning system were included in the investigations and the results were compared with the previous APM technology with condenser microphones.

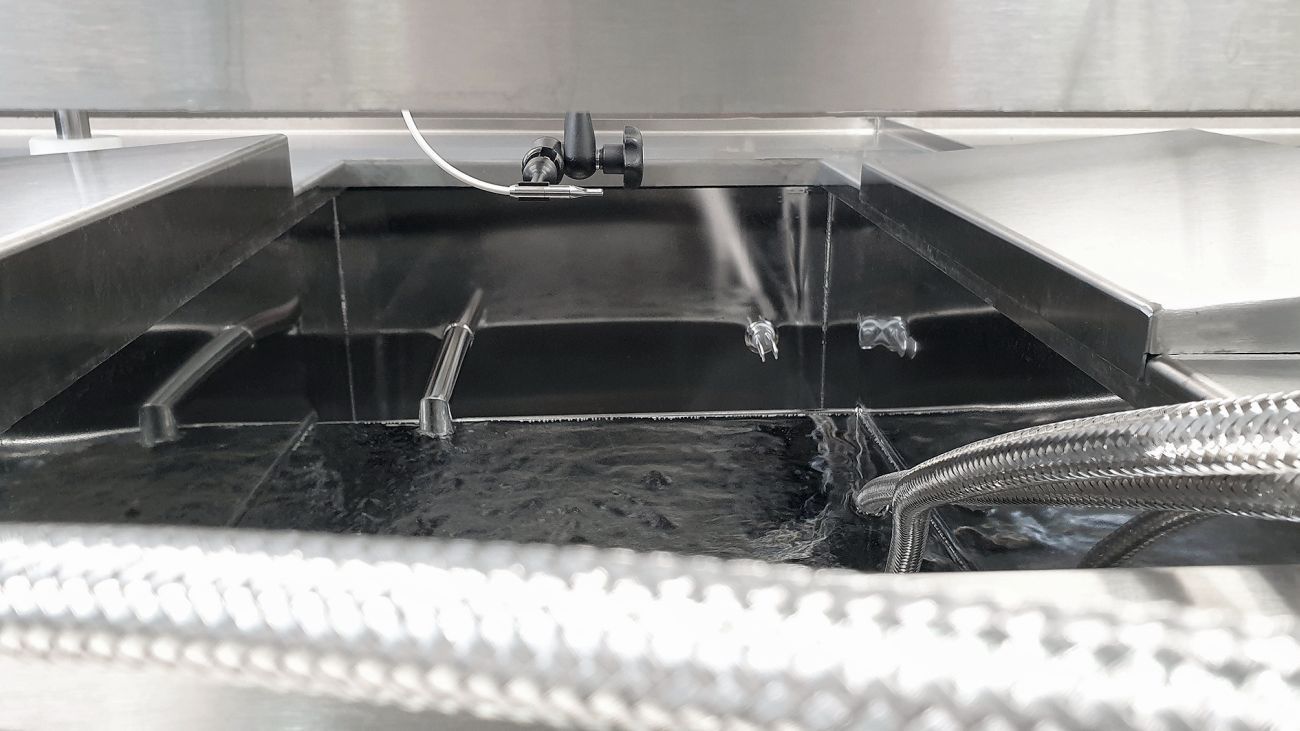

The laser acoustic microphone is located above the bath surface for the tests. The measurements are carried out without direct contact with the medium and without movement

The laser acoustic microphone is located above the bath surface for the tests. The measurements are carried out without direct contact with the medium and without movement

On the one hand, the tests demonstrated that the signal-to-noise ratio is high enough across the entire frequency band to detect sound waves up to 2 MHz. On the other hand, the aim was to determine at what distance from the bath surface the laser acoustic microphone must be used so that an adequate frequency spectrum can still be calculated despite the increasing attenuation of the sound waves by the air as the frequency increases. Due to the high sensitivity of the laser acoustic microphone, the distance is comparable to the condenser microphone used to measure low-frequency ultrasound.

Advantages of contactless and motionless measurement

In contrast to hydrophones, measurement with the APM solution takes place without direct contact with the medium and without movement. This results in various advantages. For example, contamination of the media by the measuring system is ruled out and it can also be used in applications with aggressive chemicals without contaminating the bath or damaging the measuring technology. The motionless measurement also ensures that it can be carried out reproducibly and inline. In addition, APM technology makes it possible to detect ultrasonic frequency and sound pressure even through "walls". It can therefore also be used in closed cleaning and rinsing tanks, which are required, for example, when using pressure change processes (vacuum flood cleaning processes such as PPC - Pulsated Pressure Cleaning), as well as in chamber cleaning systems. Appropriate manual calibrators are available for a quick and simple function check of the laser acoustic and condenser microphones used for the APM system on site.

Stationary measurement or at time intervals - also as a service

The measuring system is available both as a stationary solution and in a portable version for occasional checks. In the stationary version, the microphone is attached to the automatic conveyor. The ultrasonically equipped cleaning and rinsing tanks are then approached one after the other and the measurements are carried out without contact so that the results are comparable. The values determined for ultrasonic frequency and power are transferred to the software of the measuring solution, evaluated by algorithms and compared with the previously defined and stored target values and saved. In the event of deviations, the system issues a warning or error message.

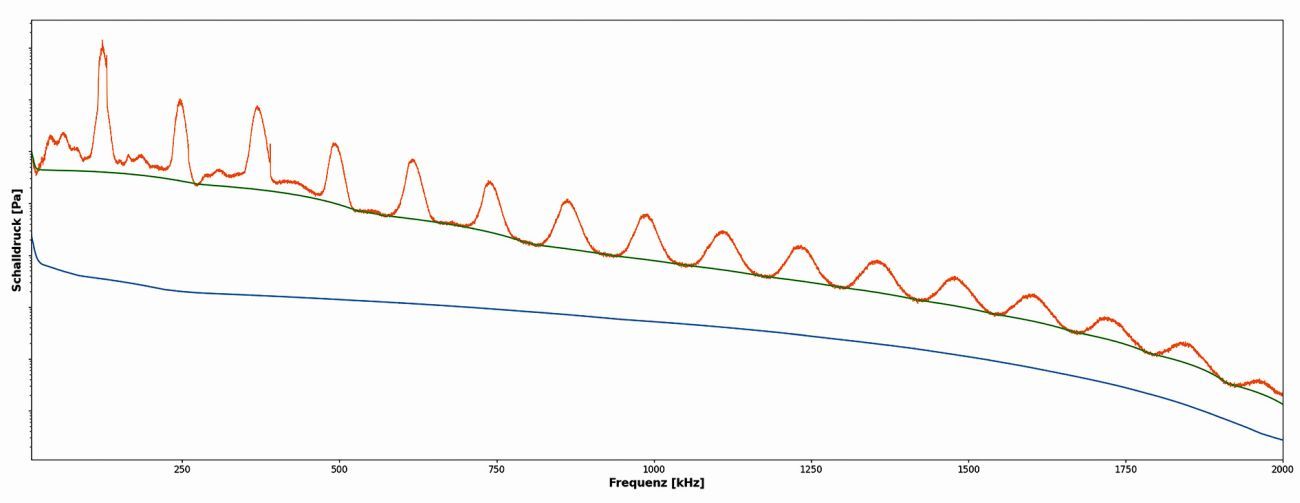

The illustration shows the frequency spectrum of a 120 kHz oscillating system (orange) and the background noise of the measuring system (blue) with laser acoustic microphone

The illustration shows the frequency spectrum of a 120 kHz oscillating system (orange) and the background noise of the measuring system (blue) with laser acoustic microphone

Users who use the classic APM system for low-frequency ultrasound, but also use ultrasound with frequencies above 132 kHz, for example in rinsing processes, can simply swap the microphone and evaluation unit and monitor both low-frequency and high-frequency ultrasound.

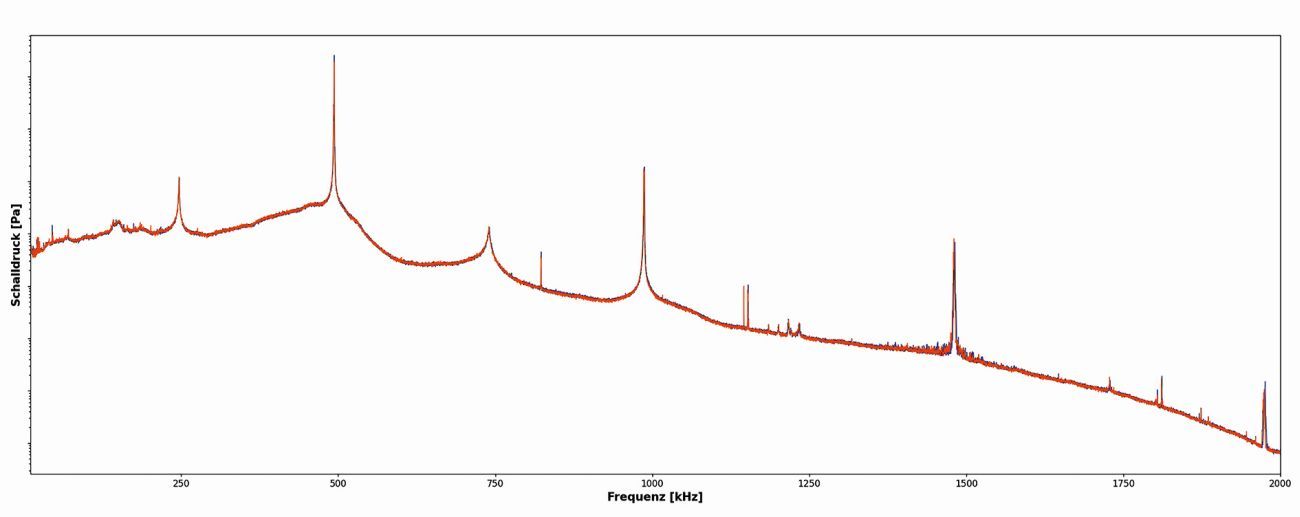

To record the ultrasonic signals of the 500 kHz oscillating system, the microphone was offset horizontally by 160 mm between measurements. The distance to the bath surface was 200 mm. The practically superimposed curves (blue and orange) show that the horizontal position of the laser acoustic microphone is not significant for the measurement

To record the ultrasonic signals of the 500 kHz oscillating system, the microphone was offset horizontally by 160 mm between measurements. The distance to the bath surface was 200 mm. The practically superimposed curves (blue and orange) show that the horizontal position of the laser acoustic microphone is not significant for the measurement

For measurements with the portable version, the microphone is aligned to the respective ultrasonic tank using a holder and records the vibration spectrum in the tank. During analysis and evaluation by the software, the measured actual values are compared with the target parameters defined as reference values for the respective treatment station. All measurements are documented in PDF reports for seamless verification. The company also offers mobile control measurements as a manufacturer-independent service for cleaning systems in which ultrasound is installed.