Magna International Stanztechnik GmbH achieved a cycle time reduction of up to 25% by modernizing the control system of its CDP system. The partners were the plant manufacturer WTF Galvanotechnik GmbH & Co KG and the control system provider ICOM Automation GmbH.

The user

Magna International Inc. is one of the world's largest automotive suppliers, capable of manufacturing complete automobiles. The company operates 338 production facilities in 28 countries. The CDP plant of Magna International Stanztechnik GmbH in Salzgitter was completely rebuilt by Wurster Oberflächentechnik GmbH in 2008. Around 800 employees now work at the site, producing in continuous shift operation for well-known car brands. The quality, throughput and flexibility requirements placed on the modernization by Magna were correspondingly high.

Fig. 1: Transport trolley from the company WTF

The plant

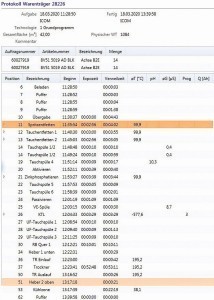

Fig. 2: Overview visualization of the GalvaCom CDC plant in SalzgitterInSalzgitter, the production steps of pressing and welding are followed by surface treatment for corrosion and wear protection of the chassis and assembly parts. Prior to implementation, the plant was operated on an order-oriented basis and without a consistently fixed control system. This often led to inconsistent pre-treatment times and thus to high fluctuations in coating quality on the one hand, and to production delays and unnecessary waiting times during loading and unloading of the cathodic dip coating (CDC) system on the other.

Fig. 2: Overview visualization of the GalvaCom CDC plant in SalzgitterInSalzgitter, the production steps of pressing and welding are followed by surface treatment for corrosion and wear protection of the chassis and assembly parts. Prior to implementation, the plant was operated on an order-oriented basis and without a consistently fixed control system. This often led to inconsistent pre-treatment times and thus to high fluctuations in coating quality on the one hand, and to production delays and unnecessary waiting times during loading and unloading of the cathodic dip coating (CDC) system on the other.

The challenge

Due to increasing call-off figures from customers and the plant management's desire to expand the product range, an increase in cathodic dip coating productivity of around 20 percent was required. For a long time, this plant was the bottleneck in the production chain. The requirements could only be met by modernizing the heart of the machine - the system control.

In terms of control technology, every second counts in high-volume production. Before the conversion project, cycle times of six to seven minutes were typically achieved, which meant that annual production was in the region of 91,980 product carriers. However, the requirements of Magna International Stanztechnik GmbH demanded that this cycle time be reduced to a maximum of five minutes. The main objective of the control system modernization was therefore to optimize cycle times and thus increase throughput while maintaining or improving product quality.

The control system supplier

ICOM Automation GmbH from Ilmenau was chosen as the supplier for the system control. The automation specialist, which has been active in the surface treatment industry for almost 30 years, is one of the leading suppliers of control systems for electroplating and waste water treatment plants. It is known throughout the industry for its ability to implement technically challenging modernizations of complex plant control systems in a short space of time.

The solution approach

ICOM Automation GmbH achieved the cycle time reduction in a two-stage process. Firstly, the work processes were accelerated by switching to control hardware with significantly higher computing power. Secondly, the path-time curve of the system's transport carriage control was analyzed in detail and the entire control and visualization software for all system components was then updated. This includes the cathodic dip coating, the conveyor systems, the dryer section with the subsequent cooling zone and the waste water system. Particular attention was paid to the improved cycle control of the wet section.

After the conversion, the clocked system was able to achieve a cycle time of 274 seconds per product carrier - 38 seconds faster than required. As a result, the Salzgitter plant achieved its previous output as early as mid-September and was able to coat an additional 21,900 product carriers during the rest of the year. The result of this control system modernization was a cycle time reduction of almost 25 percent.

The implementation

Fig. 3: Interactive KTL flow chartIn addition tothe high technical requirements, the very tight conversion schedule of two and a half weeks posed a major challenge for everyone involved. In addition to the control system conversion, maintenance work to reinforce the steel structure on the CDP line and the retrofitting of an additional fifth transport trolley were also planned during this time. This expansion of the transport capacity was necessary in order to be able to carry out the required number of transfer processes (moving the product carriers from the current to the next target bath). This was the only way to achieve the ambitious target of increasing throughput from 252 to 312 CDP product carriers per day.

Fig. 3: Interactive KTL flow chartIn addition tothe high technical requirements, the very tight conversion schedule of two and a half weeks posed a major challenge for everyone involved. In addition to the control system conversion, maintenance work to reinforce the steel structure on the CDP line and the retrofitting of an additional fifth transport trolley were also planned during this time. This expansion of the transport capacity was necessary in order to be able to carry out the required number of transfer processes (moving the product carriers from the current to the next target bath). This was the only way to achieve the ambitious target of increasing throughput from 252 to 312 CDP product carriers per day.

The plant construction

The transport trolley was manufactured by the experienced plant engineering specialists from WTF Galvanotechnik in Kratzeburg, Mecklenburg (Fig. 1).

They coordinated the mechanical work with their colleagues from ICOM, who simultaneously equipped all five trolleys with decentralized signal acquisition. The signal transmission from the transport trolleys to the central switchgear using fiber optic cables, which was no longer available, was quickly replaced with a modern optical laser data transmission system (Datalink, manufactured by Leuze) and integrated into the field bus system (Siemens Profibus DP).

The on-site conversion took just two weeks. Immediately after the planned plant shutdown, the machines were back in regular production.

The result

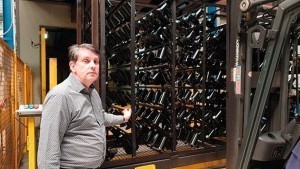

Fig. 4: Goods carrier protocol Figure 2 shows the detailed representation of the user interface of the ICOM GalvaCom control system as a result of the implementation of the new software. The processes are clearly divided into five areas: immersion pre-treatment, immersion CDP, cross transport, the CDP dryer and the cooling zone. In addition to the positions and the associated indicators for the status of the baths, product carriers and transport trolleys, the operating mode of the transport system is also displayed with automatic, manual and jog mode. In addition, information on the cycle time and duration as well as the movement of goods is provided during operation.

Fig. 4: Goods carrier protocol Figure 2 shows the detailed representation of the user interface of the ICOM GalvaCom control system as a result of the implementation of the new software. The processes are clearly divided into five areas: immersion pre-treatment, immersion CDP, cross transport, the CDP dryer and the cooling zone. In addition to the positions and the associated indicators for the status of the baths, product carriers and transport trolleys, the operating mode of the transport system is also displayed with automatic, manual and jog mode. In addition, information on the cycle time and duration as well as the movement of goods is provided during operation.

Flow diagrams of the individual pre-treatment sections and the cathodic dip coating process have also been implemented, which enable convenient interactive operation and feedback of real-time information, such as fill levels, aggregate states and other measured variables.

The visualization shown in Figure 3 was custom-developed by ICOM Automation GmbH at the request of Magna International Stanztechnik GmbH in order to maintain compliance and ergonomics for operation by the plant operators.

The basis of the system control is a powerful industrial controller (Siemens Simatic S7) with a computer-aided user interface with process visualization, data archiving, fault message transmission and backup system. The control system is integrated into Magna's production control system via a PC network. The article-specific parameters can be individually adapted by the user. The bath compositions are also kept constant via automatic dosing. To increase user-friendliness, a mobile operator panel with process visualization was installed as a control panel for the users.

The ICOM "GalvaCom" process control system offers the user various options for comprehensive process control: A productivity overview with information on the product carriers processed per shift, a rack overview to display the rack passes through the system or a report display as an archive of all messages that have occurred in plain text. The user is also provided with product carrier logs and process value curves as well as temperature and dosing overviews for analysis.

Due to the large number of parts and high quality requirements, it was also important to be able to track them at all times. To avoid losses, active parts tracking was implemented via a connection to the Magna master computer and its order management system. The machine's control system uses a barcode system to identify the type of goods and assigns the article to the treatment program stored in the database. The individual product carriers are optimized based on the previous analysis of the path-time diagram in the treatment rows, resulting in an ideal bath occupancy. This ensures the best possible system utilization while maintaining all quality-relevant parameters and achieving the highest possible throughput. In addition to automatic operation, the transport trolleys can be moved individually or manually. When the product carriers are completed, data is exported to the user's existing order management system. The production data and all treatment parameters are saved for each product and stored on the company's own server. This makes it possible to trace the entire production process, individual measured values or any errors and manual interventions that may have occurred at a later date. This documentation - shown as an example in Figure 4 - is the prerequisite for Magna to be able to manufacture precision parts for the automotive industry in the future. The entire system was equipped with Internet-based remote maintenance access. This enables ICOM Automation GmbH to provide fast and uncomplicated service at any time in the event of a fault.

www.icom-automation.de, www.wtf-galvanotechnik.de, www.magna.com

Two experts, three questions

Head of KTL department Marco KatzmartzykWhatwere the biggest challenges in modernizing the KTL system?

Head of KTL department Marco KatzmartzykWhatwere the biggest challenges in modernizing the KTL system?

Marco Katzmartzyk: I think the biggest challenge was the time we had for the conversion. At just two and a half weeks, the conversion time was very tight. That was one of the biggest challenges. Later on, the question was whether the system would start up and function smoothly and whether the project would not be delayed by another five weeks. I mean, we had to make advance runs for this period in order to buffer the time and the possibility of outsourcing orders is of course also limited in time. If there had been a significant delay, we would have incurred enormous costs. But everything went smoothly.

How satisfied are you with the new control software and how difficult was it to get used to it?

The changeover was not problematic at all. Of course, it is a change for the plant operators, but ICOM Automation has designed the operator screens in a similar way to the previous ones. Of course, some functions are a little different now and here and there something has been added or dropped, as it is now a cycle system, but the system operators have coped very well with the changeover. And the support from ICOM during the start-up phase was also great. We also had a few minor changes after the start-up, where the system operators wanted another button here or something else there. ICOM Automation simply incorporated these changes and everything went smoothly.

Technical Operations Manager Andreas GräwingholtWouldyou work together again in this way on a project like this?

Technical Operations Manager Andreas GräwingholtWouldyou work together again in this way on a project like this?

Andreas Gräwingholt: "Definitely. The highlights were very good project management, clean implementation during the conversion phase, completion on time or earlier, the subsequent very good start-up support and the trouble-free operation since then. In addition, the support after the handover of the system was flawless and good.