The Pforzheim-based JentnerGroup has digitalized its plating process end-to-end - from incoming goods to outgoing goods.

With IPS 5.0 (Intelligent Plating Surveillance), a holistic process has been created that now controls, monitors and checks the entire plating process seamlessly and traceably at all times using artificial intelligence methods. By anchoring transparency and safety in its process DNA, the JentnerGroup is thus also particularly recommended as a service provider for high-tech segments such as medical technology, aerospace and defense. The process developed in-house has also already been registered for a patent.

"IPS 5.0 documents workflows, controls all processes from the refinement of the raw products supplied through to their return to the customer and monitors them seamlessly. We can also check the results in a traceable manner at any time," says Chris Jentner, managing owner of the JentnerGroup. "Now we want to continue developing the system. To this end, we are looking for business partners and industrial customers for whom topics such as tracking and artificial intelligence are of particular interest."

Top quality and traceability

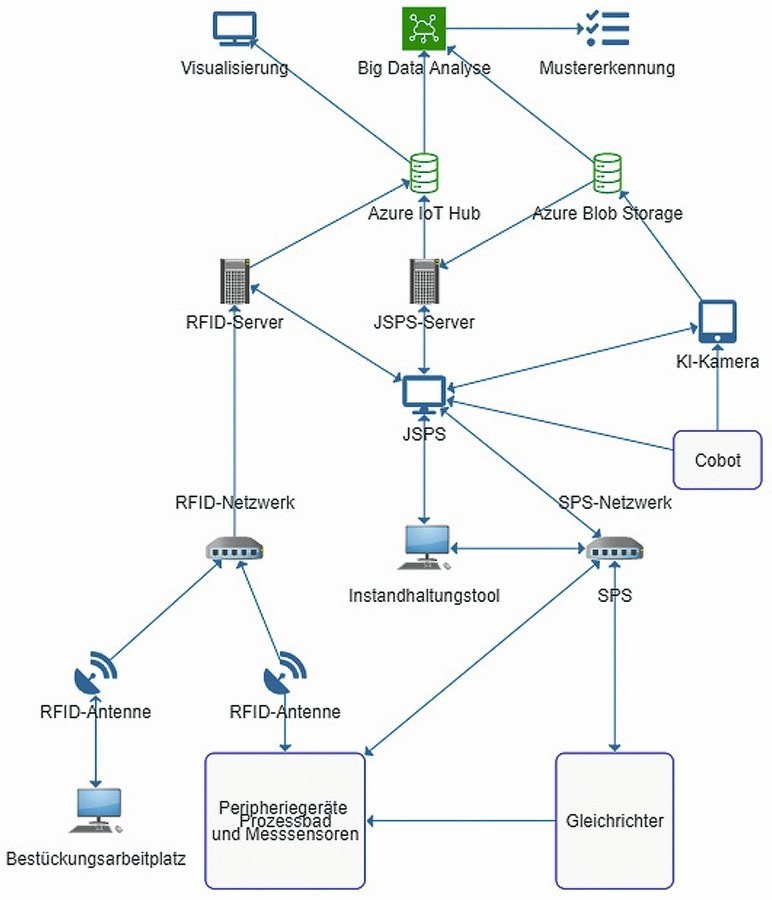

The communication structure of the IPS 5.0 control workstation The JentnerGroup had already taken the first important step towards process automation in 2019. At that time, RFID (radio-frequency identification) technology was integrated into the self-developed PDA system. This led to a significant increase in efficiency in the electroplating department through optimized plant planning, capacity utilization and error prevention. The PDA radio control system subsequently formed the basis for the development of IPS 5.0 as a significantly more comprehensive, AI-based process. It was designed in-house, selectively supplemented by the expertise of external specialists for digital transformation and robotics, software architects and web developers. Control, monitoring, AI tracking with pattern recognition and data streaming analytics: as a result, IPS 5.0 achieves significantly improved quality and makes all processes traceable down to each individual bathroom. For Jentner customers, this in turn means that they know exactly which part has been manufactured for them at all times. They can always call up the current processing status and all test results in real time via the customer portal.

The communication structure of the IPS 5.0 control workstation The JentnerGroup had already taken the first important step towards process automation in 2019. At that time, RFID (radio-frequency identification) technology was integrated into the self-developed PDA system. This led to a significant increase in efficiency in the electroplating department through optimized plant planning, capacity utilization and error prevention. The PDA radio control system subsequently formed the basis for the development of IPS 5.0 as a significantly more comprehensive, AI-based process. It was designed in-house, selectively supplemented by the expertise of external specialists for digital transformation and robotics, software architects and web developers. Control, monitoring, AI tracking with pattern recognition and data streaming analytics: as a result, IPS 5.0 achieves significantly improved quality and makes all processes traceable down to each individual bathroom. For Jentner customers, this in turn means that they know exactly which part has been manufactured for them at all times. They can always call up the current processing status and all test results in real time via the customer portal.

INFO

Jentner at a glance:

C. Jentner GmbH, like Jentner Plating Technology GmbH, is part of the JentnerGroup. Both companies are owner-managed and have been active in the field of surface technology for more than 40 years.

C. Jentner GmbH carries out electroplating on behalf of its customers. Industries include medical technology, aerospace and electrical engineering as well as functional-decorative areas. Jentner Plating Technology manufactures electroplating electrolytes and small electroplating equipment and sells them worldwide. The company philosophy is value-based and characterized by open cooperation and transparent communication.