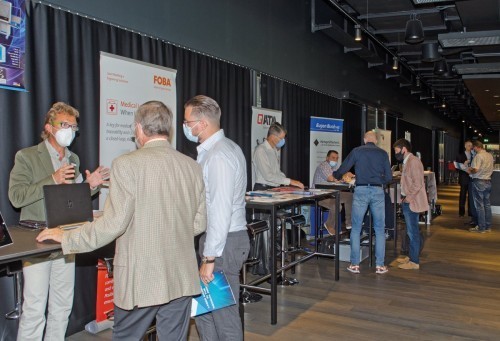

On September 1, 2021, around 50 surface technicians met in the Tissot Arena in Biel. In ten presentations, experts shared the latest knowledge on the coating of additively manufactured metal parts.

Dr. Clément Cremmel, KKS Ultraschall AG, CH-Steinen

Patrick Schmutz opens the eventElectropolishingand Anodizing of Additive Manufactured Structures

Patrick Schmutz opens the eventElectropolishingand Anodizing of Additive Manufactured Structures

KKS Ultraschall AG specializes in the surface treatment and cleaning of medical devices and instruments. In recent years, interest in printed components has risen sharply and the techniques are mature enough to achieve reproducible and reliable results. However, the post-processing of the parts poses a number of challenges. The resulting surfaces often have a high degree of roughness and a large number of semi-embedded particles. These cannot be removed using standard cleaning techniques.

KKS has therefore developed a process with which the semi-embedded particles can be removed. An electropolishing process was tested on 3D-printed stainless steel, which made it possible to improve the surfaces within the line of sight of the electrodes, but not to treat the inner surfaces.

Philippe Blanc, Swissto 12 SA, CH-Renens

3D printing & surface finishing for high-frequency components

Swissto12 is a private company headquartered in Lausanne, Switzerland, specializing in the development, manufacturing, integration and testing of state-of-the-art radio frequency systems for the telecommunications market. The coating process developed by the company consists of a chemical treatment to reduce surface roughness, followed by an electroless copper deposition to increase the electrical conductivity of the component and a silver passivation to protect against oxidation. Measurements on numerous components and in several frequency bands show that the conductivity is increased fourfold by the coating.

Daniel Müller, Rösler Schweiz AG, CH-Kirchleerau

Numerous exhibitors showed their productsPostProcessing using the example of a Formula 1 chassis insert - Sauber Case Study

Numerous exhibitors showed their productsPostProcessing using the example of a Formula 1 chassis insert - Sauber Case Study

A conventional workpiece milled from titanium is now additively manufactured. The component was permanently installed in the chassis of the F1 cars C39 and C41 for two full seasons. In racing, every gram counts and yet the highest physical requirements are demanded at the same time.

The additively manufactured workpiece in question is a class A insert component, i.e. one of the most important components in the car and has a very important and load-bearing function with the wheel fastening and the fixation for the transverse steering. It had to withstand 200,000 cycles of suspension load with 65kN tension and 30kN compression. The bonded joints also had to remain intact accordingly. The component fully met the requirements.

Martin Leuenberger, Borer Chemie AG, CH-Zuchwil

Deconex MT 41 - the innovation in passivation

Ensuring the corrosion resistance of product markings, for example with a traceable UDI code (Unique Device Identification Code) or metallic materials, is a prerequisite for permanent legibility, a guarantee for unambiguous traceability and security for permanent corrosion resistance. Complex shapes and demanding materials pose a particular challenge.

Borer Chemie AG has developed its own cleaning concept including passivation called deconex® to meet these high requirements. The customer's requirements are systematically recorded and the optimum cleaning process is developed from this. The deconex cleaning agents take into account the high standards required by manufacturers - these are developed individually and on a customer-specific basis and implemented on site at the customer's premises.

Marie-Laure Doche, Prof. Jean-Yves Hihn, Université de Franche-Comté, F-Besançon:

Electropolishing process for stainless steel parts

While technological advances in additive manufacturing (AM) have led to AM components with core mechanical and structural properties equivalent to those of forged parts, a major obstacle to the process remains the extremely deteriorated surface condition of the parts produced. The surface of the prototypes obtained is characterized by a high roughness (Ra of up to 40 μm). The use of a post-processing step to improve the overall surface quality is essential. The After-ALM (ALM for Additive Layer Manufacturing) project, which involves industrial partners such as Airbus, Safran, Liebherr, Collins Aerospace, Stelia, NavalGroup and ArianeGroup, aims to evaluate and develop relevant post-processing techniques.

This study made it possible to characterize the electrochemical behaviour of raw substrates and to define the best operating conditions that allow levelling at acceptable speeds in the order of 5 µm/min.

Dr. Patrik Schürch, Exaddon AG, CH Glattbrugg:

Additive microfabrication of metal by partial deposition

Micro additive manufacturing (µAM) of unmachined metal components has attracted a lot of attention in recent years. Despite ongoing efforts, the reliable production of such microscale 3D components remains a major challenge. The CERES system uses local electrodeposition for 3D printing of metals with sub-micrometer resolution. Metal ions are fed locally through a hollow cantilever and reduced to metal, enabling voxel-by-voxel printing.

Dr. Noémie Ott, Swiss Federal Laboratories for Materials Science and Technology, CH-Dübendorf:

Local electrochemical characterization of rough, heterogeneous materials

Corrosion processes almost always start on the material surface with local heterogeneity. A detailed characterization of material degradation at the nanoscale, especially in terms of local surface reactivity and susceptibility to corrosion, is therefore essential to accurately predict the integrity and sustainability of heterogeneous materials or additively manufactured metals. In this presentation, the Scanning Electrochemical Nanocapillary (SEN) technique will be introduced and shown to be a promising method to identify corrosion susceptible sites on rough or structured heterogeneous materials.

Dr. Roman Heuberger and others, RMS Foundation, CH-Bettlach:

Titanium powder for additive manufacturing

In this study, the effects of various influences on the mechanical and chemical properties of Ti6Al4V tensile specimens were investigated. Tensile specimens were produced in a standing and lying position using laser metal fusion (LMF, MYSINT100 RM from Sisma S.p.A., Italy) at the Swiss m4m Center. Powders from the manufacturers Sisma S.p.A. and Sandvik AB were used for this purpose. Additional influencing variables investigated were the moisture content of the powder and a thermal post-treatment to reduce stresses.

Both powders were globular, with the Sisma powder being slightly larger at 17 ± 10 µm in diameter than the Sandvik powder at 12 ± 8 µm. All tensile specimens exhibited excellent tensile strength Rm of 1100 to 1217 MPa. However, the ductility with an elongation at break of 1 to 3 % was worse than that of samples made of solid material.

Dr. Matthias Hirsch, Oerlikon AG FL-Balzers, Dr. Olivier Messé, Oerlikon GmbH D-Feldkirchen:

Inspection of metallic AM surfaces

The control of metallic AM surfaces is a critical aspect in the industrialization of additively manufactured components. On the one hand, the AM process must be optimized so that comparable components can be manufactured and, on the other hand, the post-processing steps must be designed in such a way that components are efficiently processed from "near-net shape" to the finished "net shape". Dr. Hirsch's presentation explained the approaches that Oerlikon has consistently taken to control the AM process chain.