The production chain of aviation supplier Premium Aerotec in Augsburg includes extensive surface treatment with anodizing and painting. An ambitious team led by Head of Surface Treatment Franzisca Schnizer uses modern technology and resilience to ensure the quality standards and reliability of modern Airbus passenger jets.

When it comes to aircraft production, laypeople normally think of the final assembly of large passenger aircraft in huge hangars in Toulouse or Hamburg. Anyone visiting the Airbus shipyard in Hamburg-Finkenwerder, for example, can observe an army of engineers, aircraft mechanics and many other professions completing the interior and exterior fittings of numerous Airbus models on several floors. It is easy to overlook the fundamental role played by aviation suppliers in the production process. In all Airbus production countries such as Germany, France and Spain, numerous companies, many of them Airbus-owned, contribute to the creation of a safe and technically flawless aircraft in the so-called FAL (Final Assembly Line).

Aircraft construction in Augsburg

One of the most important Airbus suppliers is Premium Aerotec, which has sites in Augsburg, Varel in northern Germany and Braşov in Romania. The company's largest location is the Fugger city of Augsburg, where aircraft have been built since 1916. Around 3,500 employees work here in four plants and carry out essential preparatory work for the Airbus models A320, A330, A350, A400M and the Eurofighter "Typhoon". Central components for the A321 XLR, the new long-haul aircraft in the Airbus A320 family, have recently been added.

Series production of aircraft fuselage structures

Plant IV of Premium Aerotec in Augsburg-Haunstetten: In the assembly hall, the whirring of cordless screwdrivers alternates with the sound of hammering and impact drilling. In the quiet moments in between, the hall is filled with radio hits from the glassed-in control room above the assembly lines. Men and women in blue overalls work between the assembly scaffolding, and industrial robots can also be seen from time to time. Here at the edge of the paint shop, the result of the assembly of tens of thousands of different components comes to light. These are meter-long fuselage components, in this case all from the tail of future Airbus aircraft, on which the openings for attaching the horizontal stabilizers can already be seen on the right and left.

30,000 different components

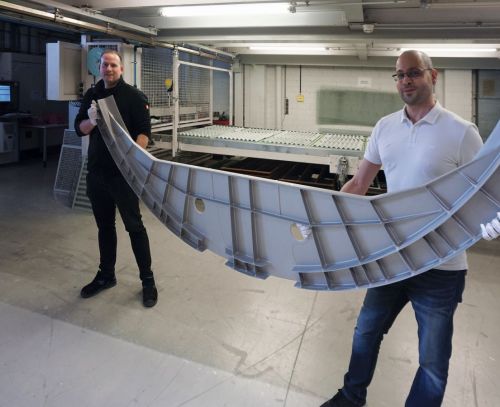

With the exception of the components made of carbon fiber reinforced plastic (CFRP) for the A350, all components have one thing in common: they need a corrosion-resistant surface coating to meet the requirements of a 30-year aircraft life. For good reason, the requirements for the coating of aluminum and, to a lesser extent, titanium components are extremely high, "because in aviation you can't just pull over in the event of a breakdown," says Franzisca Schnizer, Head of Surface Treatment, illustrating the challenges in aviation. She is the first point of contact for surface technology at Premium Aerotec and, together with the master electroplater Michael Edelmann, welcomes you to the office wing above the electroplating department. Her department with 89 employees - 42 of whom work in electroplating - delivered a total of around five million components last year. With around 30,000 different components, the range of variations is enormous and includes so-called ribs, stringers, profiles, brackets, clips, doublers and many other special components made of sheet metal, aluminum and titanium for a wide variety of aircraft applications, which are cut to size in the company's own machining park, among other things. The dimensions range from the size of a small fingernail to components six meters long and one and a half meters high, such as the massive structural component for the rear center tank of the new A321 XLR long-haul aircraft. The tank holds 10,000 liters and is responsible for the long range of the new aircraft, which is unique on the market to date.

Fully automatic electroplating machine in use

The two experts in aircraft surface technology, Schnizer and Edelmann, are particularly proud of the new electroplating facility. The baths can hold parts up to six meters long and therefore 99 percent of the product range. Coating is carried out using tartaric-sulphuric acid anodizing (TSA). The oxide layer formed on the surface must be between 2 and 7 µm thick according to the specifications. The electroplating machine installed here is arranged in two rows. Pre-treatment, including crack testing, takes place in one row, while the actual TSA process takes place in the other. The baths each have a capacity of 12,000 liters and components pass through over 30 pre-treatment and anodizing stations in both rows. On the other side of a fire protection wall, through which only cross transfer units with the coating material pass, the racks are loaded, which are transported on overhead conveyors or by means of transport trolleys to the transfer to the electroplating shop.

The main focus is on quality, which is why numerous tests are required for coating thickness, coating weight, coating closure, adhesion, susceptibility to cracking, conductivity and the traditional salt spray test. Crack testing is integrated into production. "Everything that passes the crack test is sent for anodizing," explains Edelmann, who started his training as an electroplater at Premium Aerotec in 2005. He initially worked as a normal shift worker before becoming a foreman in 2013 and a master electroplater in 2021, almost at the same time as successfully passing his master craftsman's examination. He knows the technology and processes inside out, used to work on the systems himself and also chromated until the switch from chromic acid to TSA took place. However, chromium(VI) is still used today: Premium Aerotec still operates a small bath for rivets. "The rivets are soft annealed, chromated within an hour and a half, then they go into the freezer and can later be picked up by colleagues and hammered in," says Edelmann, describing the process. He is convinced that the 1 µm thick chromate layer is still unbeatable. Franzisca Schnizer agrees and adds that chromating in Augsburg is harmless and state-of-the-art - including proper waste water treatment, which is subject to particularly stringent requirements in the water protection area. In addition to TSA and chrome, another process is also used on a small scale: if wing bearing bushes are required for Tornado fighter aircraft, a silver coating is applied, which on the one hand protects against corrosion, but also serves as a sliding layer so that the swivel wings of the Tornado can be used without damage.

New start after electroplating fire

The electroplating fire in 2018 was a challenge for Schnizer and Edelmann. Edelmann, then foreman, and his colleagues had to quickly distribute the required aircraft components to eleven electroplating plants in Germany and abroad for coating until the new electroplating plant could go into operation after around a year of construction. Electroplating suppliers such as Harter, MKV, AMT and others supplied important system components. "In terms of fire protection, they pulled out all the stops here," says Edelmann, summarizing the consequences of the fire at the time. Continuous sprinkler protection protects the system, fire compartments were defined and smoke extraction systems were installed. In addition, there is continuous temperature monitoring and the bathrooms are separated from the electrics, which are now housed in the basement. In addition, the bathrooms are no longer heated directly by electric bath heaters, but indirectly by hot water.

The last few months of the new electroplating building took place under the management of Franzisca Schnizer. As the new head of surface treatment, it was a dream come true for the mother of a then two-year-old daughter, as she now had her own production hall. Her career began in 2004 as a trained aircraft mechanic at the Airbus plant in Nordenham and led her to Augsburg around ten years ago after studying mechanical engineering and completing a master's degree in composite materials. She appreciates the combination of people, plant and technology and praises the family-friendly conditions from which the surface treatment employees in Augsburg - 30 percent of whom are female - benefit.

Helping hands wanted

Painter Christian Sturm in full safety gear in the single-part paint shopInthe assembly paint shop and in Schnizer's single-part paint shop and electroplating department, the need for new surface coaters and painters is great. Experienced electroplating employees are offered the opportunity to gain further qualifications at the technical college for electroplating technology in Nuremberg, as the in-house training workshop concentrates on the essential training course for aircraft mechanics. Premium Aerotec spares no expense when it comes to recruiting young talent. The company pays for training and further education and offers numerous other benefits. Edelmann emphasizes that interested surface coaters should be committed, quality-conscious and reliable.

Painter Christian Sturm in full safety gear in the single-part paint shopInthe assembly paint shop and in Schnizer's single-part paint shop and electroplating department, the need for new surface coaters and painters is great. Experienced electroplating employees are offered the opportunity to gain further qualifications at the technical college for electroplating technology in Nuremberg, as the in-house training workshop concentrates on the essential training course for aircraft mechanics. Premium Aerotec spares no expense when it comes to recruiting young talent. The company pays for training and further education and offers numerous other benefits. Edelmann emphasizes that interested surface coaters should be committed, quality-conscious and reliable.

The aircraft supplier is also experiencing a shortage of skilled workers in the paint shops. As there is no such thing as an aircraft painter, Schnizer also relies on vehicle painters who, in view of the current weakness in the automotive industry, want to take on new tasks to cover the demand for labor. In principle, painters, varnishers, spray painters and industrial painters are interesting for the tasks in the individual parts and assembly paint shop. "In addition to technical skills, employees should fit in with our team. We have different nationalities and cultures in the team and attach great importance to this," says Schnizer, defining the framework conditions for new employees. And the prospects for the future are certainly good. Airbus has well over 8,000 orders in its order book. With currently well over 700 deliveries per year and rising, the next ten years are secure.

The tasks in Augsburg are exciting, but also demanding, because production pressure and economic efficiency have to be juggled in a reasonable balance, which is particularly evident in the interaction between electroplating and individual parts painting. The latter is managed by Sebastian Stieb. Before becoming a master craftsman, he worked in structural assembly for the A400M military transport aircraft. He and Michael Edelmann work up a sweat especially when the daily series production for new aircraft structures is interrupted. This happens, for example, during spare parts production. If an aircraft has to remain on the ground due to defects, known in industry jargon as aircraft on ground, production has to be resumed quickly in order to contain the rapidly rising costs. This also applies to aircraft that are no longer being built, such as the A300. The spare parts business, together with components for the after-sales area, accounts for around five percent of production.

More work due to increased aircraft production

Back in the assembly hall, Christian Blank welcomes us. He is the foreman responsible for the assembly paint shop. The spacious assembly area, where the aircraft structures are assembled on scaffolding, is located between his department and the electroplating and individual parts paint shop. When the fully assembled fuselage structures arrive, the components that are difficult to access after assembly have already been painted in the individual parts paint shop. Like Franzisca Schnizer, Blank is a home-grown talent, having trained as an aircraft mechanic from 1999 before joining the production department, where he worked throughout Europe. After gaining further qualifications in his field, he was offered the opportunity to become a master craftsman in the surface area - as a career changer at the age of just 27. He picked up everything he could learn about painting at courses run by the German Research Association for Surface Technology (DFO), among others.

There are plans to increase the number of employees in the assembly paint shop in particular: from 47 now to around 70 by the middle of next year. The reason for this is an increase in aircraft production, which will also have a major impact on Blank's assembly paint shop. Numerous new components, including structural components for the rear center tank of the A321 XLR, have been added. "There are a lot of hours of work involved in this component and you need people to implement it," says Blank, explaining the increased manpower requirements.

Christian Blank inspects the inside of an aircraft fuselage in the assembly paint shop

Christian Blank inspects the inside of an aircraft fuselage in the assembly paint shop

High costs for painting and drying

Now, during the lunch break before the shift starts, there is little going on in the assembly paint shop. A huge fuselage structure stands in a paint shop, drying in a tropical climate of 35 degrees and 50 percent humidity while the team is still at work. It is a race against the clock to produce as quickly as possible so that the numerous Airbus customers worldwide do not have to wait too long for the aircraft they have ordered. At the same time, efficiency is the be-all and end-all. Industrial painting and drying processes consume huge sums of money. Efficient and fast work is therefore important. Blank demonstrates the complexity of his work inside a tail section, where he shows areas that are difficult to access.

The shortage of skilled workers, the absolute need for the highest quality in surface technology and competitive pressure are also forcing the company to automate as much as possible. Blank leads to an eight-meter-high and approximately four-meter-wide cabin in which painting robots are installed on two levels. The work platform can also be lowered by an additional four meters in order to paint the bulky fuselage components comprehensively. A further booth of this type for the automated painting of entire fuselage structures and two for manual painting are currently being set up and are already in operation in some cases. Ping pong between man and machine: the automated painting of fuselage structures is currently being expanded

Ping pong between man and machine: the automated painting of fuselage structures is currently being expanded

The coat of paint applied here is not even the last before the aircraft is delivered. Once the jet has been completed in Hamburg, Toulouse, the USA (Mobile) or China (Tianjin), the olive green primer of the fuselage structures transferred to the final assembly line is supplemented with an exterior coat of paint - after all, customers expect a flawless appearance when the aircraft is handed over.

On the way to climate neutrality

Aircraft construction in Augsburg can now look back on a 108-year tradition. During this time, aircraft production has become one of the most important employers in the region, with four plants in and around Augsburg. The prospects for the future of Premium Aerotec are good, with the decarbonization of the aviation industry playing an important role. For this reason, great importance is attached to energy and raw material efficiency, the use of solar energy and the sustainable use of water in production at Premium Aerotec.

Research projects are also maintained and new developments driven forward: Projects in the field of surface cleaning and activation as a preparatory measure for various joining processes are taking place and "form the foundation for active participation in the development of new aircraft designs", according to the company. Developers at the Augsburg-based aviation supplier have been involved in the engineering of a new door frame structure, among other things, and have tested drones for the quality inspection of surfaces in another project together with the paint and coatings manufacturer AkzoNobel (see also Galvanotechnik 11/2023, p. 1385).

The company will soon be undergoing an organizational restructuring.The Premium Aerotec sites will be integrated into the new Airbus Aerostructures GmbH in mid-2025. All aerostructures activities of Airbus' civil aviation division in Germany are bundled in this company, which is based in Hamburg. Similarly, the construction of Airbus aerostructures in France is combined in the company Airbus Atlantic.

However, this will not have a significant impact on the work in the factory halls in Augsburg - production will continue here with the same enthusiasm and vigor as ever!