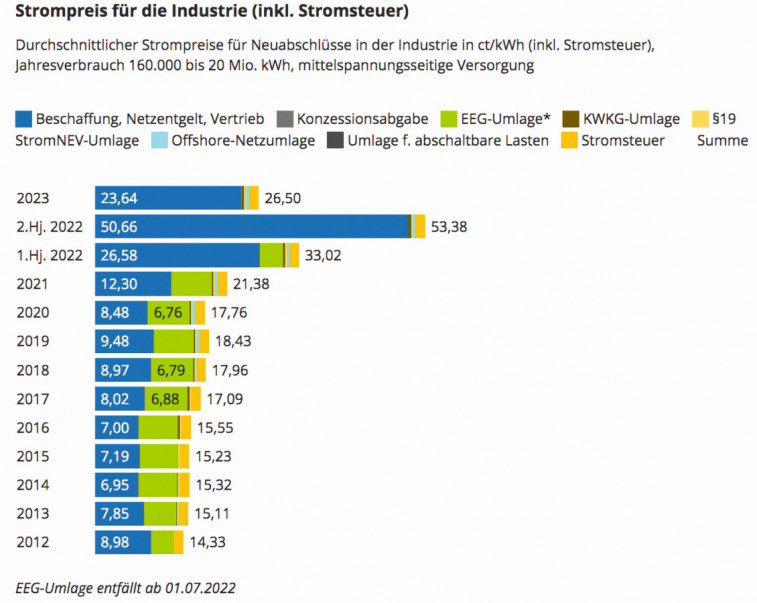

Switching to energy-saving dryer systems can save considerable costs, as Strähle CEO Sven Reimold explains in the second part of the energy-saving series. Strähle Galvanik in Zaisenhausen has been investing in energy efficiency since 2012. Since then, electricity costs for the industry have risen steadily (Fig. 1). Setting the right course for the future has significantly reduced costs. Including the EEG surcharge, the costs today would be 450,000 euros per year without energy efficiency measures. Instead, they amount to just 250,000 euros. This reduction was possible without subsidies or the use of price brakes. Part of this considerable cost reduction is due to savings on heating oil. Combining the office wing and other buildings in a district heating pipeline saves 40,000 liters of heating oil. Modern dryer systems also offer great savings potential.

Fig. 1: Composition of electricity prices in industry since 2012. Graphic: BDEW

Fig. 1: Composition of electricity prices in industry since 2012. Graphic: BDEW

Various drying systems

The well-known and very effective rack and drum dryer from Harter was installed three times as a rack dryer and once as a drum dryer at MVB (Metallveredlung Bretten), which belongs to Strähle. Even during the first installation, it quickly became clear that the appliances can save large amounts of electricity and heat. With an electric dryer, you have to reckon with a good 35-50 KW of electrical heat. Added to this is the electricity for the ventilation motors, which have to run constantly so that the heating coils, heating rods or similar constructions do not overheat and even burn out. The Airgenex system (Fig. 2) is one of the systems used. It functions as a refrigeration dryer: the warm, moist air is cooled and dried by the system. The dry, warm air is fed back into the dryer through a heat exchanger. Thanks to the lid system, which all well-known manufacturers now offer, the warm air remains in the dryer and gives the parts a uniform object temperature. Fig. 2: Airgenex dryer for rack goods

Fig. 2: Airgenex dryer for rack goods

Energy-saving and fast

Condensation dryers with heat pumps from Harter dry quickly, which means short drying times for operators. Cycle times are maintained and capacity increases in the production process can be realized in many cases. Low temperatures are gentle on products, people and materials and deliver good results without stains. Heat pump technology is inherently efficient, saving energy,CO2 and operating costs. Drying takes place in a closed air system and, according to Harter, is virtually emission-free. Operators become independent of climatic and seasonal conditions. Thanks to consistent parameters, the drying process is reproducible and reliable.

FST Drytec uses the hall air

Here, an additional fan removes the moist air from the dryer into the atmosphere up to the specified level and fresh air is simultaneously blown into the dryer through a cross heat exchanger. As a special option, a so-called blow-off rail is available, which blows off the goods for the first time as they enter the dryer and thus removes a large proportion of the water from the surface of the parts. The main advantages of the FST-Drytec drying system (Fig. 3) result from the FST drying strategy:

- Very high drying performance and very fast component drying result in very high effectiveness due to max. possible air speed and optimum drying temperature and humidity.

- High productivity and cost-effectiveness with low losses through the use of energy-saving modules result in very high efficiency.

This objective requires the consistent use of a large number of available energy-saving modules:

- the FST Jetblader blow-off system

- FST heat pump-based dehumidification with refrigeration circuit

- FST heat recovery with ERU-X cross-flow heat exchanger

- FST drying progress control and "goods dry" detection

Strähle currently uses a rack dryer and a drum dryer from FST. FST relies on processing in stainless steel, whereas other manufacturers use plastic. Everyone has to weigh up the pros and cons for themselves.

Safedry now in use at Strähle Fig. 3: FST drying system

Fig. 3: FST drying system

Safedry systems are new on the market and equipped with a technology that in principle utilizes all the advantages of the known disadvantages. They combine all the advantages of known drying systems for electroplating plants. The systems are efficient because they use energy-saving fans. An integrated blow-off function and air dehumidification for operation in open and closed systems are also possible. The units are also flexible because the system can be adapted to the customer's requirements. It can later be improved with gadgets such as drip water separators or an extension of the dehumidification system. Each system has its advantages, but they all save gas and energy and have pushed electric appliances out of the market. It therefore no longer makes sense to look at dryers with electric heating elements. Instead, you should switch to hot water heat exchangers. Another major advantage of all systems is the cover system, which keeps the heat in the system. The frequency-controlled motors can be operated at different intensities and reduce the speed and therefore the power consumption depending on the item. When the product carrier comes out of the dryer, the fans are switched off completely and a valve closes the heat circuit from the hot water. This means that nothing can overheat, resulting in further energy savings. Calculation of the savings when converting from two electrically operated trough dryers to one hot water-operated chamber dryer:

Fans: 6 x 1.75 KW = 10.5 KW

Heating coils: 12 x 3.5 KW = 42 KW

52.5 KW x 16 h = 840 KWh for a production day with two shifts. Based on the net electricity price of 9.758 cents/KWh in July, this results in an electricity price of 81.96 euros per day. Savings can also be made by shutting down fans before the end of the shift.

10.5 KW x 16h = 168 KWh x 9.758 cents = 16.39 euros per production day with two shifts. As a result, the energy costs for 50 weeks in two-shift operation fall from 20,490 to 4,097 euros. Of course, the corresponding gas price and heat requirement must be offset. The prices are individual for each company. Strähle - MVB obtains spot market prices, which fluctuate on a monthly basis. However, the energy costs will be halved.

Drying time significantly reduced

In all systems, two trough dryers could be replaced by one dryer. The drying time has therefore been halved and in some cases further reduced. Additional cost savings are achieved by the fact that the fans can be shut down or even switched off before the end of the cycle.

Moist air must come out

To ensure fast, effective drying, it is important to ensure that the warm, humid air is removed from the dryer and replaced with fresh, dehumidified air. Currently, there are still up to 40 % subsidies for energy and resource efficiency. As the subsidies and guidelines are constantly changing, each company must disclose its options individually. Unfortunately, it will no longer be quite as simple and straightforward in 2023 as it was before 2020. Everything has to be explained plausibly.

In the next issue: Energy management for heating control, pumps and units using intelligent software