Reducing costs, improving quality and minimizing rework - these are the results achieved by a contract electroplating company in Hungary by converting to heat pump-based condensation dryers in various electroplating lines. Among others, it supplies the largest chip manufacturer in Germany.

Every contract electroplater is aware of the ever-increasing demands placed on the industry. However, like everything in life, the challenges of constant process optimization also have a good side. This was the case with Feszo Trade Kft. from Budapest. Growing pressure prompted the Hungarian electroplating company to invest in an alternative drying technology in order to finally achieve spotless surfaces. Today, Feszo can boast excellent results and a good energy balance. The small company has thus further secured its place in the market. Dryer manufacturer Harter from Stiefenhofen in the Allgäu region developed this alternative type of drying back in 1991. "We have been familiar with heat pump-based condensation drying for a long time, as we used to sell sludge dryers for Harter in Hungary," explains Zsolt Lambertus, owner and Managing Director at Feszo. The drying of sludge as a waste product from galvanic processes is one of several mainstays of dryer manufacturer Harter. Feszo, in turn, was originally active as a plant planner on the Hungarian market. With the expansion and modernization of its contract electroplating facility, Feszo has now also massively expanded this business area. Lambertus adds: "When it came to improving the dryers, it was clear to us that we wanted to work with Harter again."

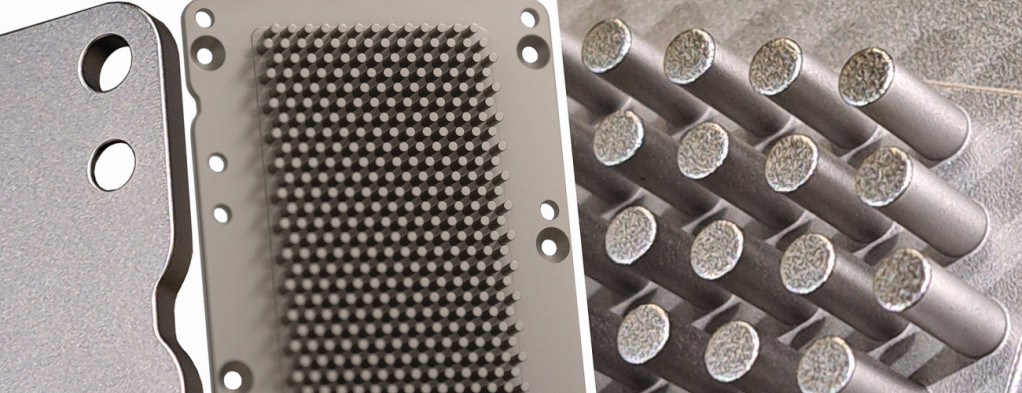

With low energy consumption, pin-fin components from a well-known chip manufacturer are now dried completely and stain-free in just 6 minutes at approx. 50 °C Feszo's relationship with the drying system manufacturer Harter from Stiefenhofen in southern Germany dates back to the end of the 1990s. Harter had just launched the completely new condensation drying system with heat pump onto the market. At the time, this was used exclusively for sludge dryers, which reduce the weight and volume of filter-pressed sludge by up to 60 %. Reinhold Specht, Managing Partner at Harter, explains: "With correspondingly high landfill costs, savings of up to 60 % in disposal and transportation costs are also possible." Sludge drying with this technology immediately experienced great demand and success throughout the German-speaking world. Feszo, as a reseller, was also among the customers in the early days. After a few years, Harter developed his technology further and optimized it for meticulous use in production processes. The large Airgenex series was born. From then on, quality problems of contract coaters and in-house electroplaters could also be solved. The gentle and, thanks to the heat pump technology, very efficient low-temperature drying finally enabled many operators to produce dry and stain-free goods - within the specified cycle time. In the meantime, Feszo has also decided to make new investments in order to continue to meet the high demands of its customers. "As Feszo itself had built electroplating systems for the Hungarian market for many years, we were able to take on the planning and project management for the four projects completed to date ourselves," says Lambertus. The first dryer was installed in an existing coating system, the following three dryers became part of new electroplating lines. And as is almost always the case with projects, Harter carried out extensive tests with the original components in its in-house technical center. This involves testing the drying properties and determining the parameters for the final solution.

With low energy consumption, pin-fin components from a well-known chip manufacturer are now dried completely and stain-free in just 6 minutes at approx. 50 °C Feszo's relationship with the drying system manufacturer Harter from Stiefenhofen in southern Germany dates back to the end of the 1990s. Harter had just launched the completely new condensation drying system with heat pump onto the market. At the time, this was used exclusively for sludge dryers, which reduce the weight and volume of filter-pressed sludge by up to 60 %. Reinhold Specht, Managing Partner at Harter, explains: "With correspondingly high landfill costs, savings of up to 60 % in disposal and transportation costs are also possible." Sludge drying with this technology immediately experienced great demand and success throughout the German-speaking world. Feszo, as a reseller, was also among the customers in the early days. After a few years, Harter developed his technology further and optimized it for meticulous use in production processes. The large Airgenex series was born. From then on, quality problems of contract coaters and in-house electroplaters could also be solved. The gentle and, thanks to the heat pump technology, very efficient low-temperature drying finally enabled many operators to produce dry and stain-free goods - within the specified cycle time. In the meantime, Feszo has also decided to make new investments in order to continue to meet the high demands of its customers. "As Feszo itself had built electroplating systems for the Hungarian market for many years, we were able to take on the planning and project management for the four projects completed to date ourselves," says Lambertus. The first dryer was installed in an existing coating system, the following three dryers became part of new electroplating lines. And as is almost always the case with projects, Harter carried out extensive tests with the original components in its in-house technical center. This involves testing the drying properties and determining the parameters for the final solution.

final solution.

Stain-free and energy-saving

All Feszo dryers are rack dryers for power electronics components. Both flat copper plates and special pin-fin base plates are nickel-plated so that they can then be soldered. They are then installed in modules that are used worldwide in motor drives, renewable energies, electric vehicles and much more. Quantities in the double-digit million range are transported through Feszo's coating tanks every year. The process for the perfectly solderable nickel layer was developed by the specialist company from Hungary itself. Due to their extremely complex geometry, the pin-fin plates are a major challenge in all processes. A high chemical load is carried over and makes the rinsing process more difficult. If it is not possible to rinse properly, this has an even greater impact on the drying process in terms of stains. If high temperatures of 100 °C are also involved, the leftovers from the sink literally burn themselves into the surface. With a proper sink, compressed air-free blowing and drying at low temperatures, the end result is stain-free surfaces - and that was the top requirement for all Feszo projects. Today, all components even pass the final quality inspection. And of course, energy also plays a major role today. The drying time for all dryers has been reduced by 70 %. What used to take 20 minutes and was not entirely satisfactory now takes just 6 minutes. After this short time, the components are completely dry and spotless. The drying temperatures today are between 50 and 55 °C, protecting people, materials and machines alike. Where gas burners used to burn 40 kW of energy, dehumidification modules with a rated output of 6.6 kW are now used in production. In addition, all dryers are equipped with an automatic cover system to keep the valuable heat in the system. For particularly complex applications, such as Feszo components, Harter equips its dryers with compressed air-free blow-off technology. This removes the coarse water load before the actual drying process begins.

Directing dry air precisely

Every Harter dryer requires a so-called dehumidification module, which prepares the required process air and is also responsible for the condensation process. Systems are sometimes designed so that one dehumidification module supplies several dryers simultaneously. The Airgenex module is always connected to the dryer via insulated pipework. On the one hand, it supplies extremely dry and warm air, which is sent over or, in the case of bulk goods applications, through the goods to be dried. For physical reasons, it absorbs the moisture very quickly. Back in the dehumidification module, this air is cooled in two stages and the water condenses out. The air is heated again in two stages and fed back into the dryer in a cycle. Harter dryers are the only systems on the market that operate with a closed air system and therefore without exhaust air. This means that operators are independent of the seasons and other climatic conditions.

However, dry air alone is no guarantee of success. What matters is the right air flow, as the unsaturated air must be directed precisely over and through the items to be dried. "We have acquired a great deal of expertise in this area over the decades," reports Specht. These great technical successes can only be achieved through a suitable combination of air dehumidification and air guidance. Lambertus believes it is well equipped for the future with the new technology: "We have better quality than before. And with today's energy prices, we benefit from significantly lower energy costs."