For thousands of years, coinage has stood for value, recognition and trust. State mints provide the flashing and jingling coins with identifying motifs and special embossing. Many pennies and collector coins also undergo the electroplating process on their way into wallets, display cases or safes.

100 euro gold coin. This collector's coin is minted at the Bavarian Main Mint (Photo: stock.adobe.com)

100 euro gold coin. This collector's coin is minted at the Bavarian Main Mint (Photo: stock.adobe.com)People have probably been trading with each other from the very beginning of their existence. For a long time, they exchanged goods and services with each other. Then - around the year 600 BC - coins first appeared as a means of payment, produced by the Lydians. This ethnic group, which settled in what is now western Turkey and whose territory also included the legendary Troy, used chunks of a gold-silver compound as a means of payment. Soon afterwards, the first motifs appeared on the coins, which remained the preferred means of payment until the eleventh century AD. Only then did paper money slowly develop as an alternative.

Coins were made of silver or gold for a long time

For a long time, coins were made of silver or gold, later increasingly also of bronze or other metal alloys. In our part of the world, the silver taler was widely accepted as coin money for a long time, followed by the groschen, pfennig, mark, cent and euro, but now without any precious metal content. However, special editions, such as the 100 euro gold coin, are still being produced and, for example, the Bavarian Central Mint in Munich is providing them with the unmistakable coinage.

Cent coin is more expensive than it is worth

The production process of a coin usually begins in a strip steel mill, which produces steel in coils and delivers them to refiners. The refiners then usually punch the strip material into blanks and knurl it. This gives the base material for the coin its round outer edge. 10 or 50 cent coins have a serrated edge, while the edge of the 20 cent coin has a few specific notches - probably also to make it easier for visually impaired people to distinguish them. Electroplating technology does not come into play for the 10 to 50 cent coin series, but it does for small change: steel coins for 1 to 5 cent coins are given a 10 to 32 μm thick copper coating. The curious thing is that the copper-plated 1 cent coin is more expensive to produce than it is worth. Last year alone, a German refiner electroplated 850 tons of steel coins for 1 and 2 cent coins.

The copper-plated 1 cent coin is more expensive to produce than it is worth

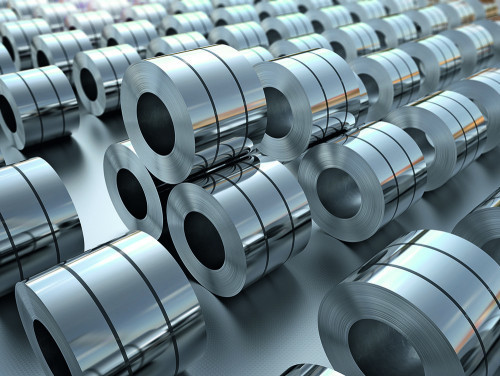

Steel coils are stockpiled in a rolling mill. The sheets are punched into rounds and knurled

Steel coils are stockpiled in a rolling mill. The sheets are punched into rounds and knurled

Drums like this one in a German electroplating plant are suitable for electroplating coins (Photo: Schlötter)

Drums like this one in a German electroplating plant are suitable for electroplating coins (Photo: Schlötter)

Coin electroplating is usually carried out in a special barrel electroplating plant. Due to the high layer thickness, the coating takes considerably longer than for other products. After an additional annealing process and processing by polishing machines, the coin blanks are ready to be delivered to the so-called mints for minting. Other currencies such as Brazilian centavos, Guatemalan quetzals or Colombian pesos are given an electroplated brass or nickel coating. What many people do not know is that these South American and other currencies pass through European electroplating plants and mints and are ultimately sold to the countries' central banks. Coins are therefore often an export product.

The quality requirements for the uncoined coins, known as blanks, are high. Electroplating plants involved in coin production use sorting systems that visually inspect the coins after electroplating. These are camera-based machines that inspect up to 2000 parts per hour on both sides. A flawless visual appearance without discoloration, rust spots or shiny surfaces is expected in the minting facilities. Attention is paid to the correct coating thickness and the perfect bond to the substrate. If the coating flakes off or comes loose after a bending test, in which the plate is bent 90 degrees over a block with a defined radius, the required quality has not been achieved.

Chrome plating by PVD in future

An important work step in coin production will no longer be covered by electroplating in future. From next year, the Bavarian Central Mint in Munich will be using physical vapor deposition (PVD) to coat the minting die surface of the coin, which was previously electroplated with chrome. The reason for the change in production process is European legislation, as Günther Waadt, Managing Director of the Bavarian Central Mint, reveals. Copper, brass, nickel and other alloys will continue to be electroplated, however. Mints win tenders in this international business and then award the contracts to electroplating companies.

However, electroplating companies are currently having a hard time with coin electroplating from a cost perspective. One manager of a company reported an increase in the proportion of energy costs from three to ten percent. Increased costs for anode materials are also an issue, particularly for nickel and copper. The price of nickel rose from 13 euros per kilo to over 50 euros, was around 20 euros for a long time and is now just under 18 euros. Copper is now even twice as expensive as it was around five years ago, says the Managing Director, describing the market situation for anode products.

10, 20 and 50 cent coins do not require electroplated layers. These coins are usually made from alloys such as aluminum bronze or copper nickel alloys, alloys that are not readily available on the market. Background: The base material is a security feature and must be clearly distinguishable from vending machines.

Mono-, bi- and triocolor coins

And what happens once the electroplating shop has delivered its goods? The Bavarian Central Mint uses horizontal and vertical minting presses to mint the blanks into coins. The stroke rates are up to 1000 strokes per minute. The cheaper horizontal presses are used for monocolor products such as 1 to 50 euro cents. Vertical presses are also used to produce various products in the bicolor range. These are the 1 and 2 euro coins with their striking shiny gold interior, framed by a shiny silver exterior. A special production center in Munich can even produce more complex coins in tricolor or coins with polymer content.

Production center for tricolor coins and coins with polymer content (Photo: Bavarian State Mint)

Production center for tricolor coins and coins with polymer content (Photo: Bavarian State Mint)

The minting tenders have incredible volumes: coin production ranges from a modest 5 million to 600 million coins. Special coins are also part of the repertoire of almost every mint. These are medals, special coins for collectors' purposes or investment coins. These special products are often given their impressive appearance on minting presses. However, they mint much more slowly, as Günther Waadt explains. The stroke rate here is only up to 80 pieces per minute. With a so-called multi-stroke system, the same piece can be embossed up to four times. As quality is the decisive criterion here, manual work still predominates for special editions. These coins can be one-offs or batches of up to 5-digit denominations.

Cash versus virtual payment

One question quickly springs to mind when it comes to the future of coin production: what if coins are abolished one day and only digital payment is used? The electroplating manager is convinced that the abolition of coins does not reflect the reality of life in many countries around the world and cites an example: "People there often have no bank accounts at all and are therefore reliant on cash." The abolition of copper coins, as recently discussed in Germany with regard to the 1 and 2 cent coins, is also of little concern to him. He argues that stores such as bakeries need the small coins because they cannot simply increase prices by 5 cents in one fell swoop.

What if coins are abolished one day and people only pay digitally?

In fact, payment by cash card has increased significantly in recent years. And yet the monetary transformation is likely to reach its limits in many areas - just think of the beggar or juggler to whom you want to slip a coin. Is it conceivable that he will pull out a card reader in future? Also, purely virtual payment is already very detached from the value perception of many people. Coins and banknotes have a haptic component that makes them more "tangible" and creates trust. This means that the cashless era is perhaps not as close as some people think - which also secures the future of an important business area for electroplating companies.

INFO

The Bavarian Central Mint

is the oldest company in the city of Munich and one of the oldest mints still in existence. As early as 1158, Emperor Frederick Barbarossa granted Munich the right to mint coins along with market and customs rights. Today, the Bavarian Main Mint, as a company of the Free State of Bavaria, still mints euro circulation and collector coins on behalf of the Federal Republic of Germany, among other things. In addition to minting national and international coins, the Bavarian Main Mint is also active in the field of contract and medal minting as well as the production of official seals. The motto of this traditional company: Coinage is trust; the Bavarian Main Mint coins trust.

The Main Mint in Munich's Zamdorfer Straße employs 53 people. Günther Waadt has been managing director here for 25 years. He has a degree in engineering and economics.