Special plant manufacturer FK Galvanik implemented a fully automated anodizing plant with 47 baths for a Dresden-based electroplating service provider. The large electroplating plant for aircraft parts sets standards in the areas of anodizing, hard anodizing, chromating and colouring. The degreasing and rinsing baths are equipped with a total of 54 ultrasonic systems from Weber Ultrasonics in Karlsbad.

The electroplating system has 47 baths and is designed for parts measuring up to 5,000 x 1,800 x 800 mm (W x D x L) It was a fire that made it necessary for Nehlsen-BWB Flugzeug-Galvanik Dresden GmbH & Co. KG to invest in a new system for anodizing/anodizing. The company, which is part of the Swiss BWB Group, is a long-standing partner of the aviation sector with numerous certifications (QSF-A/B - extended Workbench with additional capabilities) and the industry. The requirements in terms of quality, capacity and process stability as well as the size of the components that can be treated in the new electroplating system were correspondingly high. The company chose FK Galvanik GmbH, based in Keltern, Germany, as its partner for the planning, production and commissioning of the system. The special plant manufacturer has specialized in customized complete solutions for the electroplating industry for over 30 years and also covers the areas of plant modernization, expansion and conversion as well as manufacturer-independent maintenance and spare parts supply.

The electroplating system has 47 baths and is designed for parts measuring up to 5,000 x 1,800 x 800 mm (W x D x L) It was a fire that made it necessary for Nehlsen-BWB Flugzeug-Galvanik Dresden GmbH & Co. KG to invest in a new system for anodizing/anodizing. The company, which is part of the Swiss BWB Group, is a long-standing partner of the aviation sector with numerous certifications (QSF-A/B - extended Workbench with additional capabilities) and the industry. The requirements in terms of quality, capacity and process stability as well as the size of the components that can be treated in the new electroplating system were correspondingly high. The company chose FK Galvanik GmbH, based in Keltern, Germany, as its partner for the planning, production and commissioning of the system. The special plant manufacturer has specialized in customized complete solutions for the electroplating industry for over 30 years and also covers the areas of plant modernization, expansion and conversion as well as manufacturer-independent maintenance and spare parts supply.

Large system for parts measuring up to 5,000 x 1,800 x 800 mm

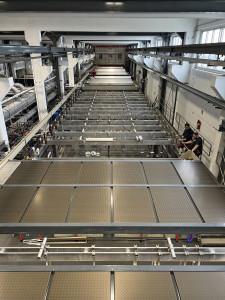

A fully automated anodizing plant was designed for Nehlsen-BWB Flugzeug-Galvanik Dresden that meets the current requirements for sustainability, efficiency and occupational safety. It can be used to carry out all the treatments performed in the three existing systems. In addition, it enables higher capacity and process flexibility so that additional market segments can be covered. The system has a total of 47 baths for parts with dimensions of 5,000 x 1,800 x 800 mm (W x D x L). The new electroplating system was installed in the renovated hall in two rows, each approximately 50 meters long and 15 meters wide.

Ultrasound for clean surfaces ready for coating

The workpieces that are electroplated pose a challenge when it comes to drill holes, undercuts and scooping geometries. Depending on the component and processing, there may be residues of processing media in these areas that are very difficult to remove. With the previous systems, they required complex, sometimes manual pre- and post-treatment. "In order to eliminate this additional effort, which is not possible in fully automated systems, and to ensure optimum quality, we have equipped the degreasing bath and the two final rinses of the pre-treatment with ultrasound," explains Dr. Thomas Kempe, Managing Director of FK Galvanik. The significantly improved cleaning effect of the ultrasound is based on the one hand on the physical effect of cavitation. On the other hand, the liquid is kept in motion by the ultrasonic currents, so that even the hard-to-reach areas are rinsed thoroughly.

The system manufacturer opted for ultrasonic components from Weber Ultrasonics. "When it comes to ultrasound, Weber Ultrasonics has been our partner for many years," reveals the Managing Director. A total of 54 ultrasonic systems of the latest technology with a frequency of 25 kHz are in use. Weber Ultrasonics AG develops, produces and markets solutions and components for the industrial use of ultrasonic technology.

Designed for high process and operational reliability

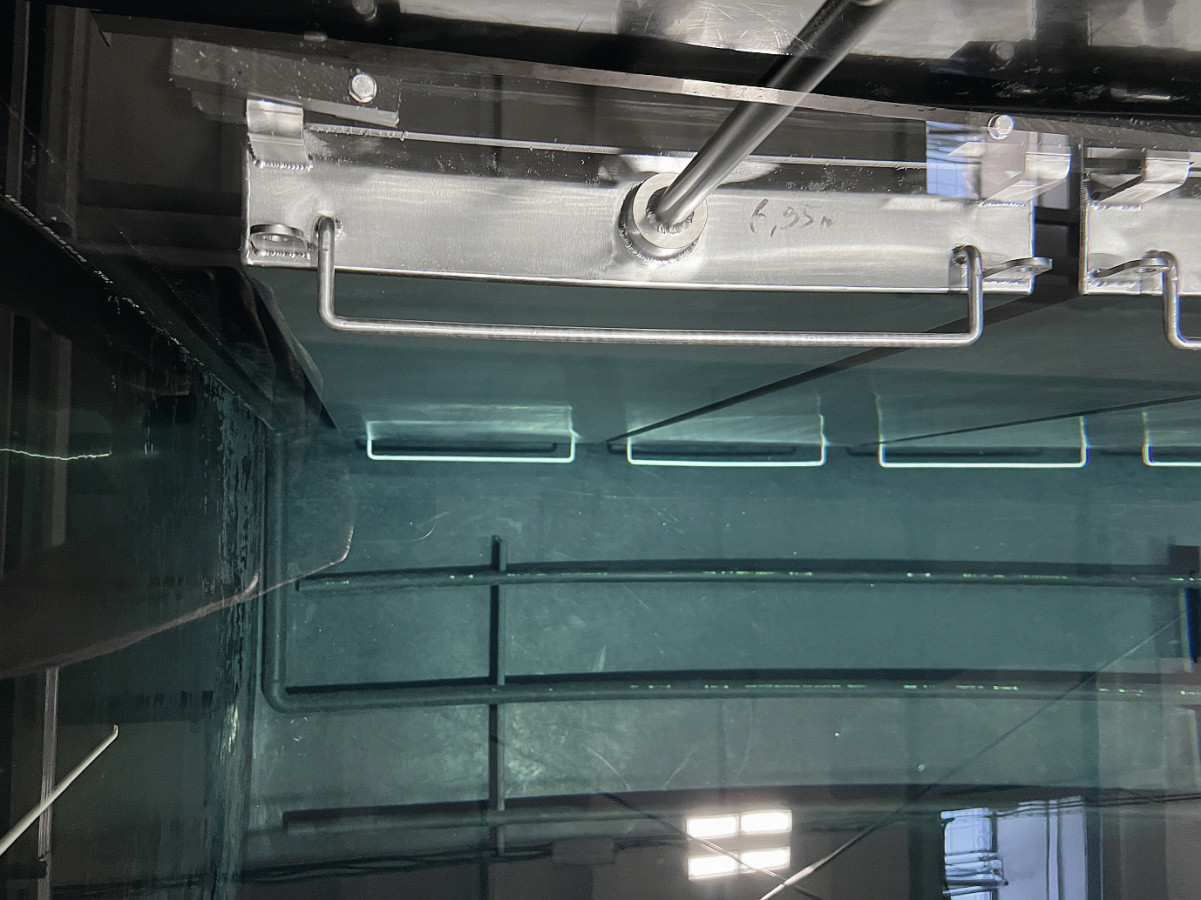

Both the degreasing bath and the two rinsing baths are each equipped with 18 Sonosub immersible transducers with adapted power ratings. Thanks to their dimensions of 1800 x 535 x 90 mm, they ensure optimum sonication of the parts in the large baths. In addition, the capsules are manufactured using a special laser welding technique, which makes the transducers extremely resistant to wear and dimensionally stable.

The digital frequency generation and control for each transducer is carried out by a fourth-generation Sonopower S3 with an output of 3,000 watts, which can be continuously adjusted between 10 and 100 %. This single frequency generator enables very homogeneous sound fields through combined frequency and amplitude modulation and prevents so-called standing waves, which improves the ultrasonic effect. "Among other things, this helps to ensure that ultrasound support can be limited to one to two minutes during cleaning and rinsing processes," reports Dr. Thomas Kempe. The Sonoscan also contributes to consistent sound power. It automatically determines the working frequency before the sound is emitted and adjusts the system accordingly. These and other patented, smart features ensure that the most efficient output is always achieved, even under changing operating conditions such as temperature fluctuations. The adjustments are made during operation so that the three-shift operation at Nehlsen-BWB Flugzeug-Galvanik Dresden can run without interruption.

With dimensions of 1800 x 535 x 90 mm, the transducers ensure optimum sonication of the parts in the large baths

With dimensions of 1800 x 535 x 90 mm, the transducers ensure optimum sonication of the parts in the large baths

The generators are equipped with an optional Profinet interface and are integrated into the Siemens control system of the electroplating plant. This allows the part-specific cleaning programs to be selected automatically.

Low energy, water and chemical consumption

For sustainable and energy-saving operation, all active baths heated by district heating and the 98 °C sealing bath have effective insulation and covers that minimize heat loss. An extraction system also ensures a pleasant temperature and humidity in the working environment. The cascade system for the rinsing baths reduces water consumption. The water from the first sink is used to compensate for liquid losses in the various active baths. The ingredients it contains also make it possible to reduce the use of chemicals.

INFO

FK Galvanik GmbH

With 30 employees, the name FK Galvanik has stood for precision in the manufacture of electroplating systems for more than 30 years. Its core competence is automatic systems for surface coating. The company specializes in the construction of these systems and the modernization and conversion of non-automated systems. The company's expertise ranges from consulting, planning, design and construction to the maintenance of electroplating systems.