In electroplating, lasers are increasingly being used for structuring, marking and applying symbols. Laser processes work without contact and are gentle on materials and tools, as a beam of light does not wear out. They are also extremely flexible when it comes to shaping. Tools do not have to be changed and workpieces do not have to be clamped in a time-consuming process. Up to now, high purchase prices have been an argument against laser technology for smaller quantities or prototype production, but suitable systems are now available.

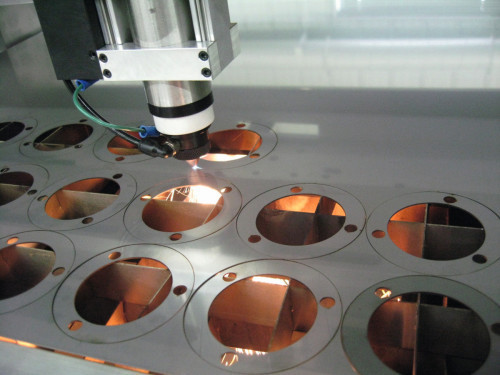

Fig. 1: The stand-alone laser cutter is particularly suitable for the production of prototypes or small seriesWhenmetals need to be cut, laser cutting systems have established themselves in many areas of series production. The technology scores with high precision, quality and speed. Even the smallest cuts can be made quickly and easily. In addition, the technology is significantly more efficient than CNC milling: with laser cutting, for example, deburring is carried out automatically in the same work step. Even complex shapes or designs are no problem for the laser. There is no chip formation, which means no contamination at the workplace, and the material around the cut remains undamaged. The workpieces are also easy to handle. Holding devices and time-consuming clamping are not necessary.

Fig. 1: The stand-alone laser cutter is particularly suitable for the production of prototypes or small seriesWhenmetals need to be cut, laser cutting systems have established themselves in many areas of series production. The technology scores with high precision, quality and speed. Even the smallest cuts can be made quickly and easily. In addition, the technology is significantly more efficient than CNC milling: with laser cutting, for example, deburring is carried out automatically in the same work step. Even complex shapes or designs are no problem for the laser. There is no chip formation, which means no contamination at the workplace, and the material around the cut remains undamaged. The workpieces are also easy to handle. Holding devices and time-consuming clamping are not necessary.

However, the technology often has a decisive disadvantage: conventional laser cutting systems are usually too inflexible for small series or prototype production away from the inline production line. Production would have to be stopped for small series or prototypes, which is not justifiable for economic reasons.

Standard laser cutting systems are usually too inflexible for small series or prototype production away from the inline production line

Innovative laser cutter for stand-alone operation

JustLaser GmbH, based in Wels, Austria, has developed a compact fiber laser system (Fig. 1) with a laser power of up to 3 kW for processing thin sheets up to 6 mm, especially for applications that require flexible laser systems for metal cutting and want to use them as stand-alone devices outside of series production. The JustCut can be used to cut a variety of metals, such as V2A and V4A stainless steel, steel, aluminum, brass or copper. With an optional round engraving device, it is also possible to process rounded and cylindrical workpieces such as pipes with a diameter of up to 153 mm. The high-power fiber laser used offers high operational reliability and beam quality as well as long-term tested reflection protection.

The laser cutter is housed in a compact housing and therefore requires little floor space. Thanks to a class 2 safety housing, it does not require a protective room and can also be used in areas with high operating volumes, for example in busy factory halls. Two practical sliding doors at both ends of the laser cutting machine ensure good accessibility. Sliding access windows are also installed on both sides. The processing area inside is 1320 x 1270 mm. Powerful CNC laser software is available as an option, which can be used to increase system efficiency and machine throughput, for example with the help of nesting, nesting and NC functions including common line, web and bridge cutting as well as lead-in functions. Another option is the k-vision package, a sophisticated hardware and software solution that allows printed material to be cut to a precise fit. Thanks to the comparatively low investment costs, there is now nothing to stop laser technology being used for smaller quantities or prototype production, even outside of automated production.

Laser marking: Efficient, flexible and fast

Laser technology can also demonstrate its advantages in product marking. Permanent markings or engravings for workpiece or product identification are in demand in many areas today (Fig. 2), in the automotive industry or in machine tool construction as well as in medical technology, electronics production, jewelry, watches or the design of advertising materials.

Fig. 2: Permanent markings or engravings for product identification are in demand in electroplating and surface technology

Fig. 2: Permanent markings or engravings for product identification are in demand in electroplating and surface technology

Cross-industry keywords in this context are traceability, quality control, branding or individualization or personalization of certain products. With the JustMark galvo lasers (Figure 3), JustLaser has two compact systems in its range that are suitable for both marking and engraving and can therefore be used very flexibly in commercial or industrial operations. They can be used quickly and easily in a wide variety of production areas and are just as suitable for individual items as they are for small or medium quantities. JustLaser advertises an optimum price/performance ratio compared to other systems. Technically, the compact lasers have a lot to offer: A special feature in this price range, for example, is the autofocus, which always guarantees the right focus and thus avoids rejects.

As the Z-axis can be controlled, stepped workpieces can also be marked and engraved. In addition, despite the compact system dimensions of 610 x 382 mm or 335 x 239 mm, the machining area is large and freely accessible. The beam path is virtually dust-tight and two air cooling systems controlled by temperature sensors at the laser source and in the housing prevent overheating. If the worst comes to the worst, the laser is switched off in good time before critical temperature rises occur. This increases the system service life.

In practice, however, labeling is usually not enough; files need to be imported and completed jobs logged. The laser software supplied imports all common vector and raster formats as well as text or Excel files. Serial and batch numbers can be generated automatically and barcodes can be created in various formats. Processed laser jobs can be logged with a time stamp. The user can process this data as required. He then knows, for example, which serial number was output at what time.

Photos: JustLaser

INFO

JustLaser GmbH

The company specializes in laser machines that engrave, cut or mark materials such as metals, wood, acrylic, plastics and textiles. The precise laser cutters, engravers and markers from JustLaser are effective tools for industrial and commercial companies.