The drums of war

Let's be honest - the world is not at peace. Many countries around the world are at war or are threatened with military action. According to the SIPRI Institute in Stockholm, global military spending has risen to a record 2240 billion US dollars in 2022. Here in Europe, the war in Ukraine is just around the corner, the Republic of Moldova feels threatened by Russia, as does Kazakhstan. In Africa, there is civil war in Sudan, while Egypt and Ethiopia are increasingly fighting over the sharing of the waters of the Nile. Iran continues to threaten Israel.

China is threatening to invade Taiwan, while North Korea - a poor country - is developing ever more powerful missiles - to what end? All this leads us to two questions. What impact will this have on our economy? And what impact could it have on our industry? To answer the first question, it seems clear that governments will spend more on the military, perhaps 3% of GNP. This means less spending on other areas of the economy. And for our industry? If there are to be more fighter planes, more warships and more military vehicles, they will all require the input of surface engineers. Many of these coatings are highly advanced, for example, they absorb radar waves and make aircraft or armored cars less visible. Military technology is constantly evolving and the war in Ukraine is in part a "test bed" for new military technology. One trend is already clearly recognizable. There is a move towards unmanned, autonomous warfare and the recent advances in AI (Artificial Intelligence) that we have all read about are already being used for military applications.

For example, the new ROBUST autonomous armored vehicle developed in Israel by Elbit Systems and the Israeli military. It has no steering mechanisms, instead each of its six wheels is driven independently so that it can turn 360 degrees almost within its own length. Propulsion is believed to be provided by a 300 hp diesel engine driving the six hydrostatic wheel hub motors, one on each wheel, with individual hydropneumatic suspensions providing maximum mobility.

In the USA, the army has adopted the Himars missile launcher that was so successful in Ukraine and developed an autonomous version (Fig. 1). The US Army is now conducting the second round of off-road tests for the Pentagon's Autonomous Vehicle (AV) program. The tests are taking place in the rugged landscape of Camp Roberts, located halfway between San Francisco and Los Angeles. The tests are part of the so-called Robotic Autonomy in Complex Environments with Resiliency project - RACER for short - which aims to develop unmanned, self-propelled ground vehicles that can move in difficult terrain.

In Estonia, the company Milrem Robotics(www.milremrobotics.com) manufactures the THeMIS (Tracked Hybrid Modular Infantry System), an unmanned ground vehicle (UGV), a ground-based armed drone vehicle developed primarily for military applications. Among other things, the vehicle is to be used to detect and eliminate booby traps. The company also offers its much larger TypeX remote support, which serves as a transport platform, remote-controlled weapon station and armored car.

Also in the air

The new Tempest jet fighter is being developed by an international consortium including Italian and British companies. It will be able to operate both with human pilots and autonomously, while autonomous drones are now widely used.

Conclusion: Some experts predict that wars will be fought exclusively with autonomous weapons in the future. In the USA, Boston Dynamics is developing "humanoid" robot soldiers and police officers, etc. However, one problem remains at present, namely providing enough energy for such robots to work for longer than an hour. Billions are being spent on autonomous weapons around the world - but very little of it here in Europe. War is always a waste of money - but unfortunately there is often no alternative.

Building a robot - piece by piece

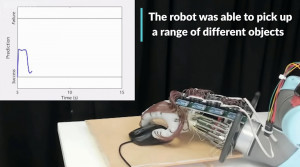

Fig. 2: The robotic hand was able to correctly pick up 11 out of 14 objectsBuildinga humanoid robot is done piece by piece, and an important element of this is the "hand" that can grasp objects or perform manual tasks. Scientists at the University of Cambridge have developed a robotic hand that can grasp and hold objects just by moving its wrist. The 3D-printed hand was developed by a team at the university. It has been fitted with sensors that allow it to 'feel' what it touches and more than 1,200 tests have been carried out, including with a peach, a computer mouse (Fig. 2) and bubble wrap. Dr. George-Thuruthel, who led the project, said: "The sensors, which function in some ways like human skin, measure the pressure exerted on the object. We can't say exactly what information the robot receives, but it can theoretically estimate where the object was gripped and with what force." According to the researchers, the technology is cost-effective and energy-efficient, as the fingers do not have to move independently of each other.

Fig. 2: The robotic hand was able to correctly pick up 11 out of 14 objectsBuildinga humanoid robot is done piece by piece, and an important element of this is the "hand" that can grasp objects or perform manual tasks. Scientists at the University of Cambridge have developed a robotic hand that can grasp and hold objects just by moving its wrist. The 3D-printed hand was developed by a team at the university. It has been fitted with sensors that allow it to 'feel' what it touches and more than 1,200 tests have been carried out, including with a peach, a computer mouse (Fig. 2) and bubble wrap. Dr. George-Thuruthel, who led the project, said: "The sensors, which function in some ways like human skin, measure the pressure exerted on the object. We can't say exactly what information the robot receives, but it can theoretically estimate where the object was gripped and with what force." According to the researchers, the technology is cost-effective and energy-efficient, as the fingers do not have to move independently of each other.

Humans instinctively know how much force they need to apply to pick up an egg - but this is a challenge for a robot. Too much force and the egg could break, too little and the egg would fall. The robotic hand was able to successfully grasp 11 out of 14 objects tested. The big advantage of this design is the range of motion that can be achieved without actuators. "We want to simplify the hand as much as possible. We can get a lot of good information and a high level of control without actuators, so when we add them, we get more complex behavior in a more efficient package."

Going green

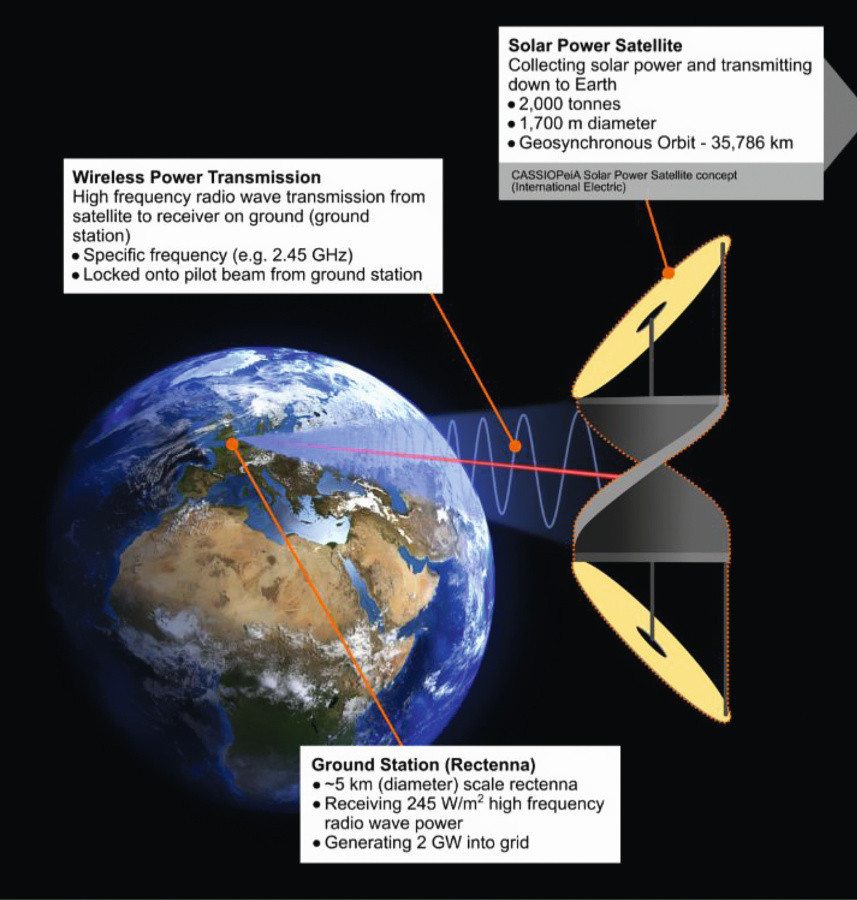

Wind and solar energy are two real success stories. Both now produce large amounts of energy at attractive prices. Their underlying technologies are slowly improving. But neither of them can supply us with electricity around the clock and so the focus is turning to other approaches. Allow me to digress here. Saudi Arabia is a very rich country - but its wealth is based almost entirely on oil. The Saudi leadership realizes that perhaps in ten years, either their oil reserves will be depleted and/or the price of fossil fuels will fall as more and more green technologies are deployed. So Saudi Arabia is investing - wisely - in new technologies for the future. In particular, the Saudis are considering solar energy - but in space. Unlike solar panels on Earth, solar energy harvested in space could provide electricity around the clock. The concept is shown in Figure 3.

Fig. 3: Concept of a space-based solar energy plant

Fig. 3: Concept of a space-based solar energy plant

The Saudi government is in talks with various partners, including the company SpaceSolar(www.spacesolar.co.uk). But they are not alone in exploring this concept. The ESA (European Space Agency) is also investigating the technology. The following link provides more information on solar energy developments around the world.

https://www.esa.int/Enabling_Support/Space_Engineering_Technology/SOLARIS/SBSP_overview

But China seems to be ahead of the game. In 2021, work began on the Bishan space solar power station in the southwestern Chinese city of Chongqing and experiments have been carried out on "beaming" energy over very long distances using microwaves. The Saudis are also in talks with Elon Musk, whose reusable SpaceX rockets could be used to build such a solar plant. What is the timeframe for this technology? SpaceSolar claims that a pilot plant could be operational within 10 years. The Chinese expect 2035 for a gigawatt plant. Everyone realizes that the cost of rocket launches will continue to fall, making it ever more economically viable. But there will be competition from nuclear power, especially the new generation of small modular reactors and perhaps later nuclear fusion units. Let's hope that Europe is not left behind.

Green flying

We have electric trains, cars, trucks and electric buses and cabs. But building electric airplanes is the biggest challenge. The reason for this is quite simple. Kerosene, the fuel for jet engines, has about 50 times the energy density of the most modern batteries. It's hard to imagine that changing. A Swedish company, Heart Aerospace (heartaerospace.com), is working with the British company BAE Systems to build the ES-30 regional aircraft.

It is powered by four electric motors and is designed to carry 30 passengers over a range of 200 km. Heart wants to extend the range by a further 200 km with a hybrid drive. This would allow the aircraft to fly from London to Brussels. If the number of passengers is reduced, the range should even be 800 km, which would allow the aircraft to fly from London to Frankfurt. Heart Aerospace is aiming to test the concept next year, flight tests in 2026 and entry into service by 2028. The company has equity from Air Canada, the airline operator, and potential orders for more than 400 aircraft, including from United Airlines, one of the world's largest airlines. Some believe such an aircraft would primarily be a replacement for helicopters. But when major airlines support the project, it should be taken seriously. There are only two "green" alternatives. One is the production of "green" aviation fuel. This is known in England as SAF (Sustainable Aviation Fuel) and is made from organic waste or specially grown plants. However, not only is it more expensive than normal kerosene, it also seems impossible to ever produce it in sufficient quantities. The other approach would be to use hydrogen, probably in jet engines, which are hardly any different from those currently in use. GlobalCO2 emissions from airplanes account for about 2% of total emissions, and hydrogen seems to hold the most promise for reducing emissions.

Storage of liquid hydrogen

Fig. 4: Storage tank for liquid hydrogen at low temperaturesWhetherfor airplanes or other applications, it seems certain that we will need to store hydrogen, in most cases as liquid hydrogen at low temperatures. It is therefore obvious that there are many studies looking into the design and construction of such storage tanks.

Fig. 4: Storage tank for liquid hydrogen at low temperaturesWhetherfor airplanes or other applications, it seems certain that we will need to store hydrogen, in most cases as liquid hydrogen at low temperatures. It is therefore obvious that there are many studies looking into the design and construction of such storage tanks.

The UK's National Composites Centre (NCC) is one of the organizations developing this technology. It has announced details of its cryogenic storage tank test program, which will accelerate development, including a carbon fibre tank without a liner for storing liquid hydrogen (Fig.4).

Cryogenic storage tanks are needed for H2-powered aircraft, which are expected to enter service in the mid-2030s. Most designs for liquid hydrogen storage focus on relatively heavy metal tanks, while the composite tanks developed in the aerospace industry are more suitable for low-cycle (filling and discharging) applications. In comparison, commercial H2 aircraft require the lightest possible fuel tanks that can withstand high cycles and have a lifespan of several decades.

To support the UK's transition to a low-carbon economy, the NCC is developing fundamental knowledge for cryogenic composite tanks and conducting tests on product demonstrators of increasing complexity. Engineers have designed and built a range of cryogenic systems for the handling and transfer of liquid hydrogen.

Smart textiles - mass production

We have all heard of so-called "smart textiles", which have various properties, both active and passive. Some can be used to display images, while others monitor bodily functions such as blood pressure. Until now, such textiles could only be produced using very specialized equipment. Now a team from Cambridge has developed a new type of smart fabric that can be woven on industrial looms to incorporate a variety of flexible electronic devices into clothing.

"You could make these textiles in specialized microelectronics facilities, but that requires billions of euros in investment," said Dr. Sanghyo Lee of the Cambridge Department of Engineering. "Also, making smart textiles this way is very limited because everything has to be made on the same rigid wafers used to make integrated circuits, so the maximum size you can achieve is about 30 centimeters in diameter."

To make the smart fabrics compatible with conventional textile machines such as industrial looms, the team in Cambridge coated the material to make it particularly stretchable. The researchers then mixed electronic, optoelectronic, sensory and energetic fiber components in various configurations with conventional fibers. The fiber components were connected using an automated laser welding process with electrically conductive adhesive. To illustrate the capabilities of the new fabrics, the team produced a 46-inch woven demonstrator.

In collaboration with textile manufacturers, the team was able to produce test panels of smart textiles measuring approximately 50 x 50 cm, but scaled up to larger dimensions and produced in large quantities. According to the researchers, flexible displays and monitors could be produced more cheaply on industrial looms than on specialized electronics manufacturing equipment.

"These companies have well-established production lines with extruders and large looms that can automatically weave one square meter of textile," says Lee. "So when we introduce the smart fibers into the process, the result is basically an electronic system that is manufactured in the same way as other textiles."

Truly form-factor-free industrially scalable system integration for electronic textile architectures with multifunctional fiber devices: Sanghyo Lee et al. SCIENCE ADVANCES, 9 (2023), No. 16, April 21, 2023