In anticipation of a new German government

Many friends of Germany around the world, but especially here in Europe, are eagerly awaiting the news of the formation of a new German government. It will certainly have to be a coalition, and by the time the November issue of "Galvanotechnik" reaches you, dear readers, the new government may already have been formed. Of course, there is much speculation about which parties will be represented in a new coalition - but I leave such speculation to my much better-informed German colleagues.

However, Germany's many friends are entitled to speculate about the policies of a new German government. This speculation focuses mainly on two areas. Firstly, what will the energy policy of a new German government look like? And secondly, at a time when many Western countries increasingly view Russia and China as hostile powers, what will Germany's relationship with these two superpowers look like? In Germany itself, perhaps a quarter of all voters - the younger voters - have never experienced a government other than the CDU/CSU. And of course there will be many judgments - some positive, some critical - both in Germany and abroad about Angela Merkel's 16 years of leadership. I would like to make one comment at this point, namely that while Mrs. Merkel was at the helm of Germany - the European economic powerhouse - she never exploited her potential power. She will certainly benefit from this. It is already clear that Mr. Macron will apply for the unofficial leadership of Europe after the departure of "Mutti". We will have to wait until next April to find out what the French voters have to say!

German energy policy and new technologies

We all know that the Green Party is quite strong in Germany. But will it also be represented in a new coalition? If so, it will certainly shape energy policy in Germany. But the Greens have a problem. They are against nuclear power, they are against fossil fuels such as natural gas, coal and oil. We know that the phasing out of coal-fired power generation is being discussed by some parties in Germany. Can a modern society be powered exclusively by renewable energies? Most experts are of the opinion that this is not possible, or at least not without energy storage on a scale that we have not yet seen. Batteries? Or hydrogen storage with fuel cells? The Greens are against nuclear power, which they envision as huge CHP plants, typically up to 4 GW. They have not forgotten Chernobyl or Fukushima. Many others in the world are also against such huge plants, simply because they are enormously expensive and are invariably completed many years late. The Flammanville nuclear power plant in Normandy is - who knows? - five times over budget and ten years late, maybe more. In Finland, construction of Olkiluoto (Unit 3) started in 2005 and it could be that it will be operational in 2022, also about 3 million over the original cost. In the UK, the Hinckley Point KK plant is also late and over budget. But would the German Greens also be against completely new types of nuclear power? I will come back to that later. If the German Green Party is against the use of fossil fuels, what do they think of fossil fuels combined with so-called "carbon capture and storage", where theCO2 is trapped underground? This technology has not yet been successfully demonstrated on a large scale anywhere in the world.

Germany's relationship with Russia and China

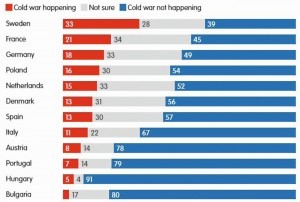

Fig. 1: European views on the danger of a cold war with China In recent years, some Western nations, first and foremost the USA, have slowly but surely come to regard Russia and China as hostile powers. Peaceful coexistence is no longer a political goal. Countries such as Japan and South Korea have increased their military spending, with the Japanese Liberal Democratic Party planning to double military spending from 1% to 2% of GDP, an increase of around USD 50 billion per year. Taiwan is living under the Chinese sword of Damocles and there is no peace in Ukraine.

Fig. 1: European views on the danger of a cold war with China In recent years, some Western nations, first and foremost the USA, have slowly but surely come to regard Russia and China as hostile powers. Peaceful coexistence is no longer a political goal. Countries such as Japan and South Korea have increased their military spending, with the Japanese Liberal Democratic Party planning to double military spending from 1% to 2% of GDP, an increase of around USD 50 billion per year. Taiwan is living under the Chinese sword of Damocles and there is no peace in Ukraine.

In addition to the increases in military spending, there is a quieter but long-term strategy to reduce our dependence on Chinese technology, e.g. semiconductors. The new word is "resilience" and the US is building several new domestic semiconductor plants, called chip foundries. Australia is increasingly fearful of the threat from China, as we saw recently when they entered into the Aukus agreement, which includes the purchase of nuclear submarines. Many friends of Germany are concerned about the close relationship with Russia and China. I am not a critic of Northstream 2, which could be completed in a few weeks. There is a desperate energy shortage in Europe at the moment and without Northstream 2 there could be serious shortages this winter. I note that although the pipeline is almost finished, it has not yet been officially approved - a very strange situation. However, I firmly believe that natural gas supplies from Russia should be seen as temporary, as a breathing space while we develop our own sustainable energy sources. Is Germany doing this with sufficient speed?

In the meantime, the fighting in eastern Ukraine continues and sooner or later Western powers, including Germany and the EU, will be forced to intervene. Germany and the EU may be forced to help Ukraine - or it may suffer the same fate as Crimea. The European Council on Foreign Relations recently conducted a survey on Europeans' attitudes towards China. The question was: "Do you think we are entering a cold war with China?" and the answers are shown in Figure 1. This shows that the vast majority of Europeans do not believe this, with Sweden being an exception. These views are in striking contrast to those in the US and Australia.

Germany has many close economic ties with China, mainly because of its massive exports there, but also because of the large Chinese investments in Germany. If China were to take military action, for example on its border with India, in the South China Sea or elsewhere, it would be extremely difficult for Germany today to ally itself with other Western nations without suffering significant economic damage. China today has enormous economic power and has shown its willingness to use this power to achieve its political goals. The new German government will have to accept the unpleasant truth that while the German economy is strong, it is dependent on the continued goodwill of Russia and China.

Future prospects for nuclear power

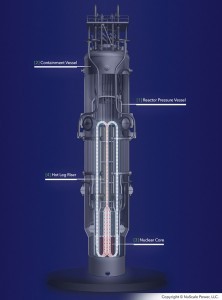

Fig. 2: The Nu-Scale nuclear reactor According to EU regulations, nuclear power is not classified as a "green" technology. President Macron wants to change this and has formed a coalition with Bulgaria, Croatia, Finland, the Czech Republic, Hungary, Poland, Romania, Slovakia and Slovenia. As nuclear power projects are a "green" technology, private investors would then be entitled to EU climate protection subsidies. Germany has committed to closing its remaining nuclear power plants by 2022 and its anti-nuclear policy is supported by Austria, Ireland and Italy. In October, President Macron announced a €30 billion "Green Futures" technology plan, including €1 billion for the development of so-called SMR (Small Modular Reactor) nuclear power plants. Plans to develop similar plants have already been announced by Rolls-Royce. It is worth noting that France and the UK are the only two European countries that have nuclear-powered submarines and could use this expertise to develop land-based SMRs.

Fig. 2: The Nu-Scale nuclear reactor According to EU regulations, nuclear power is not classified as a "green" technology. President Macron wants to change this and has formed a coalition with Bulgaria, Croatia, Finland, the Czech Republic, Hungary, Poland, Romania, Slovakia and Slovenia. As nuclear power projects are a "green" technology, private investors would then be entitled to EU climate protection subsidies. Germany has committed to closing its remaining nuclear power plants by 2022 and its anti-nuclear policy is supported by Austria, Ireland and Italy. In October, President Macron announced a €30 billion "Green Futures" technology plan, including €1 billion for the development of so-called SMR (Small Modular Reactor) nuclear power plants. Plans to develop similar plants have already been announced by Rolls-Royce. It is worth noting that France and the UK are the only two European countries that have nuclear-powered submarines and could use this expertise to develop land-based SMRs.

President Macron is effectively forcing the EU to make a decision on nuclear power and it is clear that there are very different views on both sides. It should be noted that several of the 10 countries in President Macron's alliance already have nuclear power plants.

There are at least 50 companies developing SMRs worldwide. In Russia, there are 6 icebreaker ships powered by KK and using RosAtom technology. Russia is building or planning many more such units, mainly to supply energy to industry in remote parts of Siberia and elsewhere. In the US, Nu-Scale (https://www.nuscalepower.com/technology/design-innovations) has now received official approval for its technology and is planning a plant in Idaho. Nu-Scale has also reached agreements with government agencies in Poland and Ukraine. Figure 2 shows the reactor module with a capacity of 60 MW (electrical) and 77 MW (thermal). Plants would consist of units of 4, 6 or 12 such reactors with a total capacity of approximately 500MW.

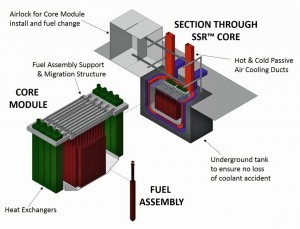

In Canada, Moltex has developed its own technology, the SSR (Stable Salt Reactor, Figure 3). Moltex claims that it is so compact that a 1200 MW plant could be transported on a single truck. The projected cost of electricity is around US$45/MWh. The reactors can be operated with spent fuel from existing nuclear power reactors, eliminating the need to store highly radioactive waste. No radioactive gases are produced during operation, making the technology inherently very safe, and the reactor operates at normal atmospheric pressure. Moltex has also developed the technology for hydrogen production using its technology.

Fig. 3: Moltex SSR unitAll ofthese reactors appear to be uranium-based. However, China has recently announced the development of thorium-based technology. Such reactors are inherently safer than uranium-based ones, and thorium is both abundant and cheaper. Thorium reactors were developed in the US from the 1940s but were mothballed in 1969. The new Chinese reactor is small and has an output of only 2 MW. It is cooled with molten salt and can therefore be operated anywhere. The new reactor is located in Wuwei, in the province of Gansu. Will the USA now revive its own thorium technology?

Fig. 3: Moltex SSR unitAll ofthese reactors appear to be uranium-based. However, China has recently announced the development of thorium-based technology. Such reactors are inherently safer than uranium-based ones, and thorium is both abundant and cheaper. Thorium reactors were developed in the US from the 1940s but were mothballed in 1969. The new Chinese reactor is small and has an output of only 2 MW. It is cooled with molten salt and can therefore be operated anywhere. The new reactor is located in Wuwei, in the province of Gansu. Will the USA now revive its own thorium technology?

Conclusion: Worldwide, it seems clear that we are now experiencing a "reactor race", with huge prices for those who are first on the market. It seems to be a problem for some in Germany whether to participate in this new technology or not. But all is not lost for the Greens. The technologies I have described above are all fission core power and are close to being ready for the market. A little further in the future is nuclear fusion, which could be acceptable to the Greens. There are also promising developments in solar technology that would certainly be welcomed by green politicians. I plan to report on this next month.

New old material wood

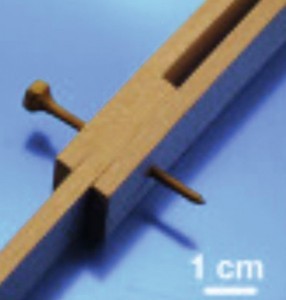

Scientists have produced a wooden blade that is almost three times as sharp as a stainless steel table knife and more than 20 times as hard as conventional wood. The same material has also been used to make wooden nails that are as sharp as steel nails and strong enough to be driven in with a hammer (Fig. 4).

Fig. 4: Wooden nail"The knife slices effortlessly through a medium-rare steak, with similar performance to a dinner knife," says Professor Teng Li, a materials scientist at the University of Maryland who led the research. Afterward, the knife can be washed and reused, making it a promising alternative to steel, ceramic and disposable plastic knives, according to Li and his colleagues. The wooden nails also have the advantage that they do not rust. "Cellulose, the main component of wood, has a higher strength-to-density ratio than most engineering materials such as ceramics, metals and polymers, but our current use of wood barely exploits its potential." To make the knife, the wood is first immersed in a chemical bath to remove a substance called lignin, which serves to bind the cellulose together. "This step makes the originally rigid natural wood soft, flexible and a little squishy," says Li.

Fig. 4: Wooden nail"The knife slices effortlessly through a medium-rare steak, with similar performance to a dinner knife," says Professor Teng Li, a materials scientist at the University of Maryland who led the research. Afterward, the knife can be washed and reused, making it a promising alternative to steel, ceramic and disposable plastic knives, according to Li and his colleagues. The wooden nails also have the advantage that they do not rust. "Cellulose, the main component of wood, has a higher strength-to-density ratio than most engineering materials such as ceramics, metals and polymers, but our current use of wood barely exploits its potential." To make the knife, the wood is first immersed in a chemical bath to remove a substance called lignin, which serves to bind the cellulose together. "This step makes the originally rigid natural wood soft, flexible and a little squishy," says Li.

The material is then heated to 105 °C and pressed. This removes water from the material and increases its density. The result is a piece of hardened wood that is 23 times harder than the natural wood from which it was made. It is then coated with mineral oil to make it waterproof and extend its life.

The method used by the scientists has reduced or eliminated the natural defects of the wood. Their material could also be used to make hardwood floors that are more resistant to wear and tear.

Source: Hardened wood as a renewable alternative to steel and plastic Bo Chen, et al. Matter, Issue: October 20, 2021 DOI: https://doi.org/10.1016/j.matt.2021.09.020

The pleasure of Italian cuisine

Fig. 5: Inside the largest vertical farm in EuropeManyEnglish people today enjoy Italian cuisine. They may have been slower than their German cousins to discover the taste of pasta and pizza, but Italian dishes are now an accepted part of everyday life. There's just one problem: many of the ingredients can't be grown here in the UK and have to be imported. That has now changed. In Scunthorpe, an unglamorous industrial town in the north of England, a relatively unknown company, the Jones Food Company (www.jonesfoodcompany.co.uk), is quietly running the largest so-called vertical farm in Europe. The large windowless former warehouse is operated at 28°C and 78% relative humidity. It is illuminated with 12 km of pink LEDs (Fig. 5). Currently, only one product is grown there - the herb basil, a key element in many Italian dishes. And this one plant now covers around 50% of the UK's entire basil requirement. The shelves, which are stacked 19 layers high, have an area equivalent to 26 tennis courts or 5000 square meters. In just 19 days, a single seed grows into a small, market-ready basil bush, and the plant can produce over 400 tons per year.

Fig. 5: Inside the largest vertical farm in EuropeManyEnglish people today enjoy Italian cuisine. They may have been slower than their German cousins to discover the taste of pasta and pizza, but Italian dishes are now an accepted part of everyday life. There's just one problem: many of the ingredients can't be grown here in the UK and have to be imported. That has now changed. In Scunthorpe, an unglamorous industrial town in the north of England, a relatively unknown company, the Jones Food Company (www.jonesfoodcompany.co.uk), is quietly running the largest so-called vertical farm in Europe. The large windowless former warehouse is operated at 28°C and 78% relative humidity. It is illuminated with 12 km of pink LEDs (Fig. 5). Currently, only one product is grown there - the herb basil, a key element in many Italian dishes. And this one plant now covers around 50% of the UK's entire basil requirement. The shelves, which are stacked 19 layers high, have an area equivalent to 26 tennis courts or 5000 square meters. In just 19 days, a single seed grows into a small, market-ready basil bush, and the plant can produce over 400 tons per year.

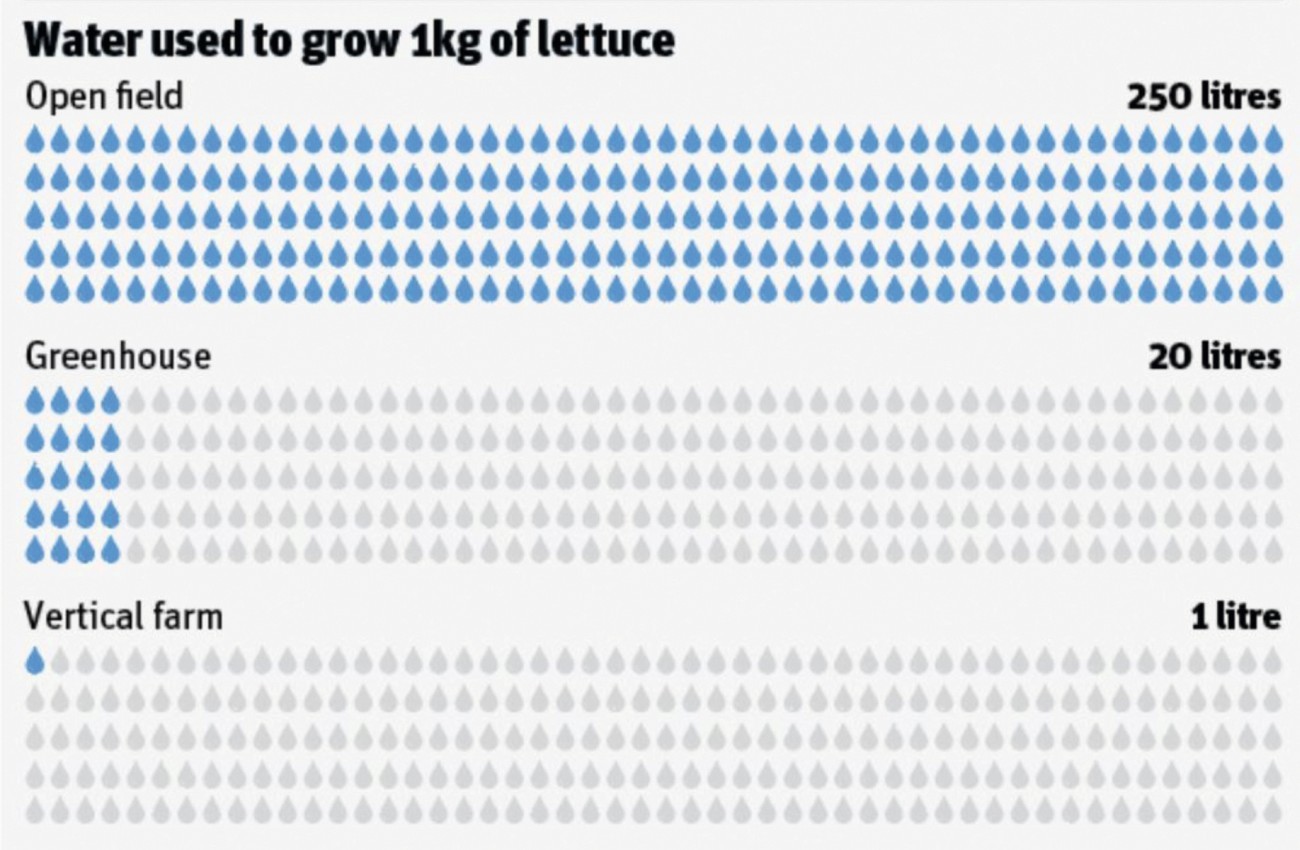

What about profitability? The plant described here has only 6 employees. Other important key figures are shown in Figures 6 and 7. Figure 6, which shows the low water demand, will be crucial in countries like Africa where water scarcity is a growing problem. The key technology that has enabled vertical farms has been the development of low-cost LEDs and solar panels. It is more efficient to use electricity from solar panels to power the LEDs than to use direct sunlight to grow the crops. Bayer is just one leading German company that recognized the potential of this new technology early on and has its own subsidiary, Unfold GmbH. Numerous new farms of this type are currently being opened in the UK, Europe and around the world. The Jones Food Company plans to grow flowers, spinach, chard and rosemary as well as other vegetables and fruit. It will be up to the metal fabricators and our industry to develop the most cost effective metal racks and trays that this technology relies on.

Fig. 6: Vertical farming uses less water

Fig. 6: Vertical farming uses less water

Fig. 7: Vertical farming makes optimum use of land areas

Fig. 7: Vertical farming makes optimum use of land areas

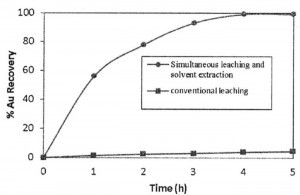

After 1100 years - a revolution

Fig. 8: The new method is much faster than conventional gold leachingTheBritish Royal Mint is probably the oldest mint in the world. It has been producing coins and medals for over 1100 years and supplies dozens of nations worldwide. But with the growth of the digital economy, it's clear that the demand for coins will decrease. But as we use fewer and fewer coins, we are also generating huge amounts of 'e-waste', which contains valuable metals, not least gold, platinum and palladium. The WEEE Forum estimates that over 50 million tons of e-waste will be generated in 2021 (more than the Great Wall of China weighs!). E-waste is worth around 60 billion US dollars a year, and most of it is never recycled. E-waste contains many chemical elements whose global reserves are almost exhausted. Currently, most of it is waste and is never recovered. The Royal Mint has teamed up with Canadian company Excir (www.excir.com), which has developed a new leaching process that works at room temperature and only takes a few seconds. Figure 8 shows how much faster gold leaching is with the new process compared to conventional methods. Google (https://patents.google.com/patent/US20180112289A1/en) provides a link to the key patent as well as links to prior art and similar patents. The key patent is US 2018 0112289 A1. It describes the classical methods of metal (ore) leaching - cyanide, thiourea, thiosulphate, chloride/hypochlorite and organic leaching agents. The new approach in this patent is a 3-component solution consisting of an acid, an oxidizing agent and an organic solvent that is either completely or partially miscible with water. The acids mentioned are the most common mineral acids, the oxidizing agents include chlorine and H202, and the organic solvents include acetic acid, ethyl acetate and acetonitrile. So it can be said that it is nothing really new or exotic. Leaching times range from a few seconds to 30 minutes at room temperature or < 100 Celsius. The patent is 23 pages long and has over 300 citations. By and large, most surface technicians are not concerned with leaching. In contrast, metal coating stripping is very important in our industry and this new approach will certainly be adopted soon.

Fig. 8: The new method is much faster than conventional gold leachingTheBritish Royal Mint is probably the oldest mint in the world. It has been producing coins and medals for over 1100 years and supplies dozens of nations worldwide. But with the growth of the digital economy, it's clear that the demand for coins will decrease. But as we use fewer and fewer coins, we are also generating huge amounts of 'e-waste', which contains valuable metals, not least gold, platinum and palladium. The WEEE Forum estimates that over 50 million tons of e-waste will be generated in 2021 (more than the Great Wall of China weighs!). E-waste is worth around 60 billion US dollars a year, and most of it is never recycled. E-waste contains many chemical elements whose global reserves are almost exhausted. Currently, most of it is waste and is never recovered. The Royal Mint has teamed up with Canadian company Excir (www.excir.com), which has developed a new leaching process that works at room temperature and only takes a few seconds. Figure 8 shows how much faster gold leaching is with the new process compared to conventional methods. Google (https://patents.google.com/patent/US20180112289A1/en) provides a link to the key patent as well as links to prior art and similar patents. The key patent is US 2018 0112289 A1. It describes the classical methods of metal (ore) leaching - cyanide, thiourea, thiosulphate, chloride/hypochlorite and organic leaching agents. The new approach in this patent is a 3-component solution consisting of an acid, an oxidizing agent and an organic solvent that is either completely or partially miscible with water. The acids mentioned are the most common mineral acids, the oxidizing agents include chlorine and H202, and the organic solvents include acetic acid, ethyl acetate and acetonitrile. So it can be said that it is nothing really new or exotic. Leaching times range from a few seconds to 30 minutes at room temperature or < 100 Celsius. The patent is 23 pages long and has over 300 citations. By and large, most surface technicians are not concerned with leaching. In contrast, metal coating stripping is very important in our industry and this new approach will certainly be adopted soon.