Atonarp

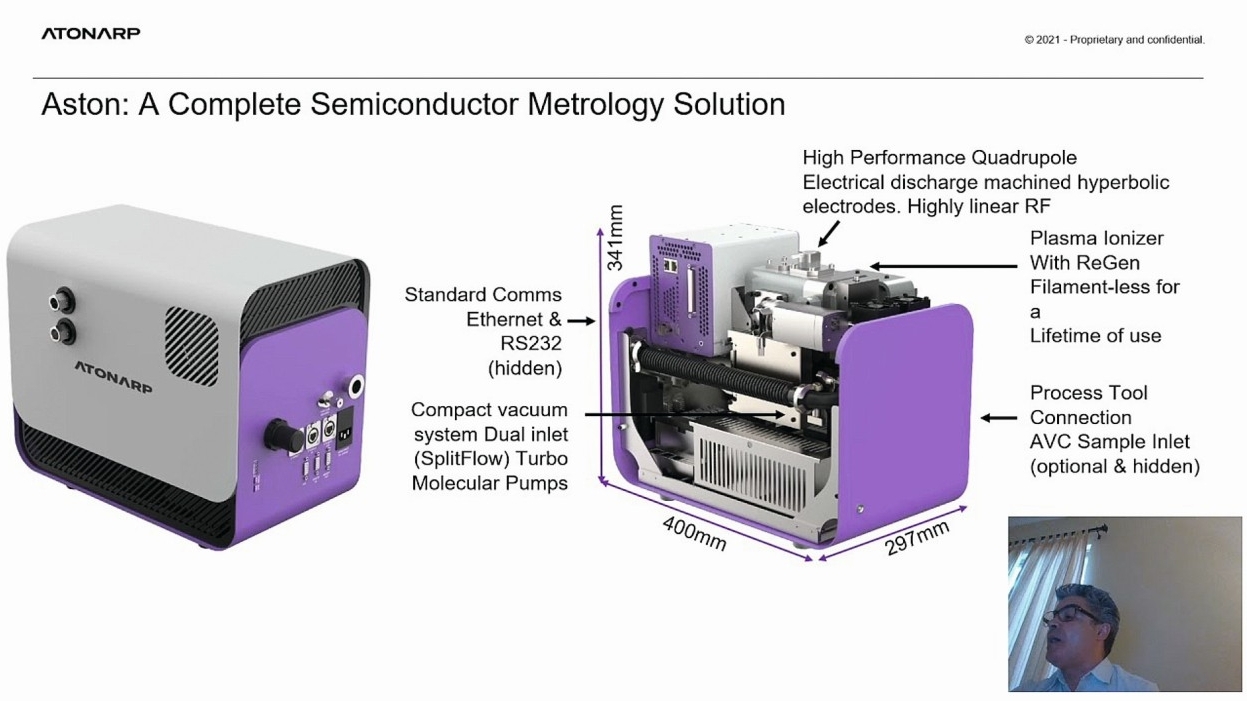

Tokyo-based Atonarp Inc. is an innovative developer of instruments and processes for the semiconductor industry and life sciences, which are also used in other industries. It recently announced the development of a miniaturized smart spectrometer. Here, the usual instrument component sets are miniaturized and optimized for an ultra-small form factor. At the heart of the technology platform is a powerful processor coupled with proprietary software algorithms that deliver resolution, sensitivity, accuracy and speed. The instrument is highly configurable and the flexibility guarantees real-time data analysis. The Smart Spectrometer® can be used in a wide range of applications thanks to its versatility. Process analysis applications for industrial gases - especially in the energy, pharmaceutical, petrochemical and semiconductor industries - are envisaged.

In semiconductor manufacturing, low κ dielectric deposition is a common process, but requires frequent cleaning of process chambers to remove the accumulation of deposition condensates. Atonarp's Aston takes a new approach with accurate end-point detection to reduce processing time. Aston has already been successfully used in low κ dielectric deposition applications. The total chamber cleaning cycle in an In-FAB production study was reduced by up to 80%. The total time for depositing wafers and cleaning the chamber in a five-wafer cycle was reduced by more than 40 % (Fig. above).

Vacuum pumps are generally reliable, but in harsh semiconductor manufacturing processes they can fail unexpectedly, leading to costly downtime and damage to the wafers. However, many process and chamber cleaning gases are corrosive, and during CVD coating everything becomes covered in condensate particles. Conventional measurement solutions such as residual gas analysis are susceptible to corrosive gases and can corrode after just a few hours of operation. Atonarp's Aston metrology platform provides actionable information in real time. Aston, with its resistance to corrosive gases, supports data-driven modeling of pump failures by enabling the measurement of gases entering and exiting the dry pump to predictively model destructive corrosion or deposits.

In diagnostics, refining clinical outcomes and improving the overall patient experience begins with fast, accurate and painless diagnostic tests. Atonarp's latest molecular sensing technology enables clinical-level diagnostics without the use of typical laboratory nasal chemistry. The ATON-360 takes a snapshot of molecular structures and uses the company's proprietary software platform to analyze and determine the type and amount of analytes present in the sample - all digitally.

Prakash Murthy, the founder of Atonarp and a native of India, has lived in Japan for more than ten years.

https:// www.atonarp.com/products/aston

White pigments from zinc electroplating sludge

Zinc phosphate is known as a white anti-corrosion pigment for a wide range of different primer applications. Zinc phosphate primer is used for overcoating. The adhesion and corrosion protection of paints and varnishes are improved with zinc phosphate. A high-quality white-grey primer based on zinc phosphate is generally known. Zinc phosphate is also used in the production of dental cements, among other things.

A Russian-Belarusian research group has developed a process to produce zinc phosphate from ammonium chloride-based zinc electroplating waste water. If the iron content is controlled, zinc phosphate can be precipitated by adding a sodium phosphate solution and the filtrate can be discharged into the sewer. The organic additives do not significantly interfere with the process. The degree of whiteness of the precipitate was 98% and the product was suitable for industrial application, according to researchers Valentin Romanovski from the Research Center for Structural Ceramic Nanomaterials, NUST MISIS and Olga Zalygina from the Belarusian State Technological University.

https://en.misis.ru/university/news/science/2021-10/7606/

Tebulo Blade Coating

Automated coating systems have been around for several decades. Recently, robots have been increasingly used to further refine the automated process. Robot-based processes are becoming increasingly important, especially for oversized and complicated parts, e.g. rotor blades(both Fig.)

Warmenhuizen-based Dutch high-tech industrial solutions developer and equipment supplier, TebuloRobotics, recently held a demonstration of its latest autonomous mobile robot (AMR) for precision coating of rotor blades, which is tailored to precisely these requirements. The AMR's four electrically driven, 360-degree rotating wheels enable precise and unrestricted movement in all directions. In addition, the vehicle has many other innovative features, including state-of-the-art External Guided Motion (EGM) technology, which allows complex 3D shapes and curvatures of turbine blades to be tracked without the need to pre-program detailed product dimensioning in the robot. For precision coating of a blade, the advanced spray head from Dutch start-up Qlayers is attached to the arm of the robot. Other integrated support systems include a device for removing excess paint particles with built-in extraction and cleaning filter units, all integrated into the carrier vehicle. The 'clean' air is then released back into the coating area through vents in the lower part of the vehicle.

It is the first robot of its kind to be able to coat without overspray thanks to the state-of-the-art and patented Qlayers coating head technology. Possible additional AMR applications include non-destructive inspection of the laminate, sanding and cleaning of surfaces, precision coating and polishing and the application of additional features such as vortex generators.

https:// www.tebulorobotics.com/wp-content/uploads/2020/11/Tebulo-Robotic-Wind-turbine-blade-coating-AGV-and-EGM-based-.pdf

https:// www.windpowermonthly.com/article/1706644/exclusive-robot-trial-looks-speed-production-large-wind-turbine-blades

Other

Tata Technologies has developed a scalable modular platform eVMP in Pune, which is described as the first complete turnkey solution for manufacturing electric vehicles. The platform is also said to be able to shorten the process of ideation, supplier management, testing, verification and launch from 36-45 months to 25-27 months.

There are car manufacturers that keep the original design of an ICE car but replace the engine with an electric motor.

In Malaysia, D&O Green Technologies Bhd recently acquired Syntronixs Asia Sdn Bhd, a precision electroplating services company in Melaka, for RM55 million (about EUR12 million). Syntronixs is known as a provider of precision electroplating services to the semiconductor industry. Syntronixs offers effective surface cleaning solutions and pre-treatment processes, namely deburring and descaling of parts prior to the plating process.