As part of the project, new hybrid processes were developed in teamwork that combine conventional manufacturing processes with laser material deposition (LMD) and three robots to create a new manufacturing approach. The four chefs behind the recipe for success come from the German Federal Ministry of Education and Research (BMBF), the Karlsruhe Institute of Technology (KIT), KUKA Industries and the Fraunhofer Institute for Laser Technology ILT.

"From the very beginning, the project has been characterized by the fact that all project partners have approached the research work in a highly motivated and well-coordinated manner," says Dr. Helmut Bossy. He is a consultant and deputy head of Department 521 "Future of Work and Value Creation; Industry 4.0" at the BMBF, Bonn.

Opportunity for SMEs: A more cost-effective version of the ProLMD robot cell for hybrid additive manufacturing using laser deposition welding, adapted to the needs of small and medium-sized companiesInfact, initial successes in laser deposition welding of small structures on large-area components were quickly achieved on the basis of the work at the Fraunhofer ILT together with the user companies. Helmut Bossy found it innovative that two approaches were merged here: powder and wire welding. Another positive aspect is the hybrid approach, which combines the advantages of other conventional manufacturing processes, such as machining or primary and secondary forming, with this additive technology.

Opportunity for SMEs: A more cost-effective version of the ProLMD robot cell for hybrid additive manufacturing using laser deposition welding, adapted to the needs of small and medium-sized companiesInfact, initial successes in laser deposition welding of small structures on large-area components were quickly achieved on the basis of the work at the Fraunhofer ILT together with the user companies. Helmut Bossy found it innovative that two approaches were merged here: powder and wire welding. Another positive aspect is the hybrid approach, which combines the advantages of other conventional manufacturing processes, such as machining or primary and secondary forming, with this additive technology.

It is usually the case with funded projects that there are financial or legal hurdles to overcome. In this project, however, these hurdles were comparatively low. Dr. Bossy: "First of all, the group of experts who advised us on the selection of projects classified this project as highly innovative and recommended it for funding. Incidentally, the scientific findings on additive manufacturing will only find their way into practice once the researched and developed processes work reliably under industrial conditions."

In order to achieve this gradually, but also within a reasonable period of time, three demonstrators were required in this case. At the Fraunhofer ILT, the scientific understanding of the process was deepened and the necessary improvements were made to the powder and wire heads of the existing plant technology. A further system was required to link the various system components, such as robotic welding in a controlled atmosphere and non-contact measurement technology for quality assurance - all under industrial requirements. With the experience gained from both systems, the findings could then be incorporated into a further system design at the Fraunhofer ILT. This is specially tailored to medium-sized companies, for example in terms of availability and simple handling of the rather complex additive manufacturing processes.

The project management and cell integration of the robot was the responsibility of KUKA from Würselen, represented by Günter Neumann. Neumann is Head of Business Unit Laser Applications at the company. When KUKA acquired Reis Robotics in 2015, it also took over Reis Lasertec in Würselen, near the Fraunhofer ILT Aachen, in order to further expand the good contacts that already existed at the time. KUKA's doors were therefore wide open when they offered to manage the project. In any case, additive manufacturing is a target market in which robot technology can set standards. There are already specialized machine tools that are now coming onto the market. A standardized robot cell makes this cheaper, although the disadvantage is that this process can never achieve the precision of a machine tool. But this precision is not needed everywhere.

Neumann is optimistic: "With ProLMD, we have now proven that the robot is capable of implementing additive laser manufacturing after all. Experts have not seen the robot being used in this area. This is a very important point that has now emerged from the project."

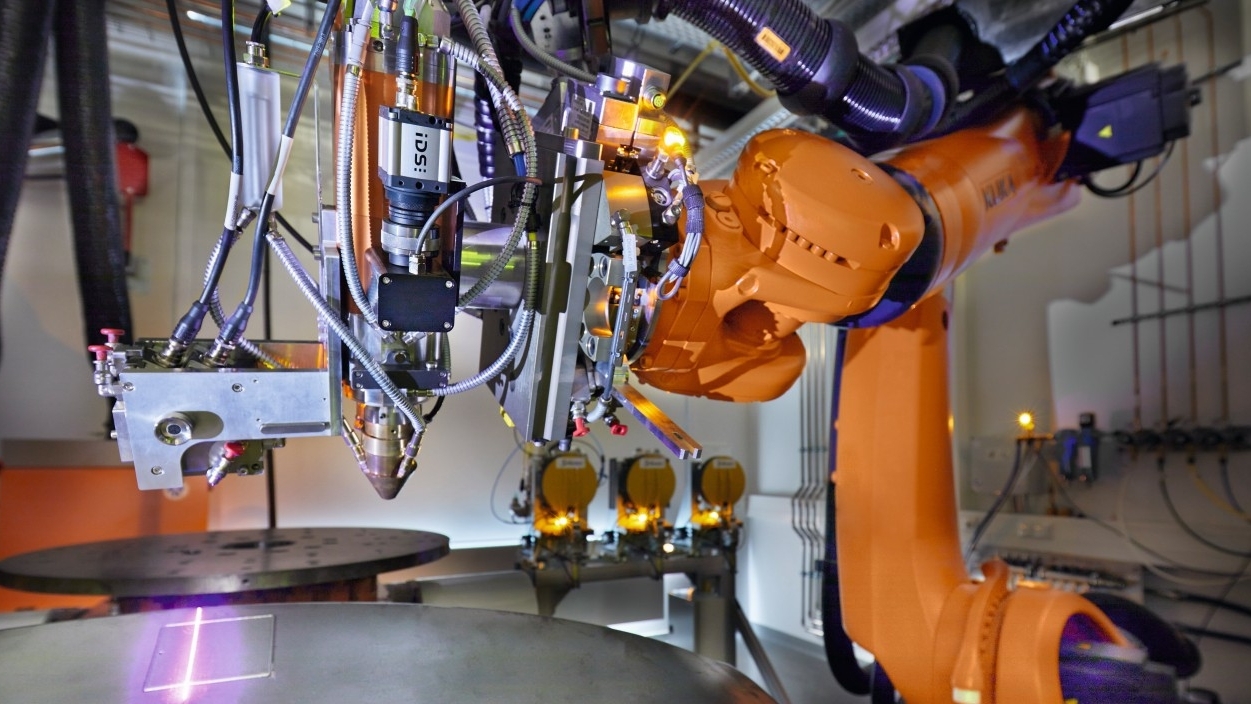

System for laser deposition welding with robot support and shielding gas cell for aerospace applications, at ProLMD project partner KUKA in WürselenWithadditional financial support from the BMBF, a cheaper version of the ProLMD robot system for small and medium-sized enterprises (SMEs) was also developed at the Fraunhofer ILT. This means that additive manufacturing with the robot can also be considered for small jobs. It was a fortunate circumstance that solutions for SMEs could also be developed specifically as part of the project. Günter Neumann: "We can now say with a clear conscience at any time: Hello SMEs, our basic version of the cell is an economical solution for numerous applications".

System for laser deposition welding with robot support and shielding gas cell for aerospace applications, at ProLMD project partner KUKA in WürselenWithadditional financial support from the BMBF, a cheaper version of the ProLMD robot system for small and medium-sized enterprises (SMEs) was also developed at the Fraunhofer ILT. This means that additive manufacturing with the robot can also be considered for small jobs. It was a fortunate circumstance that solutions for SMEs could also be developed specifically as part of the project. Günter Neumann: "We can now say with a clear conscience at any time: Hello SMEs, our basic version of the cell is an economical solution for numerous applications".

Metallic 3D printing is particularly important in Aachen. The Fraunhofer ILT was the first institute in Germany to focus completely and comprehensively on the topics of digitalization, additive manufacturing (AM) and 3D printing. This has led to the development of a growing community that also thinks about the topic from a design perspective. Although laser cladding is well known in the field of coating, it is still a relatively new technology in the field of additive manufacturing and a very promising process with many advantages, as material only needs to be added locally, allowing much larger components to be created. Additive manufacturing normally works in layers and therefore only slowly. Compared to the classic casting or forming process, it is otherwise often cost-intensive. It is now a huge step forward that the process has been enabled for fast and cost-effective production. It can also be seamlessly integrated into existing process chains.

Professor Johannes Henrich Schleifenbaum holds the Chair of Digital Additive Production DAP at RWTH Aachen University. Until September 2020, he headed the "Additive Manufacturing and functional layers" competence field at Fraunhofer ILT. Schleifenbaum sees a further advantage in this project, namely that it contributes to thinking more in terms of process chains. Schleifenbaum: "I think that's a very important point. Added value is created along the interfaces between domains. We now cover the entire process chain and define the interfaces along the maturity levels of the processes. This is the only way to create a truly functional process chain that can also be used in industry. That is already unique. It's almost like squaring the circle that we are now making this technology completely available to industry in a project like this." As the saying goes, many cooks spoil the broth. Well, many cooks were involved in the ProLMD project. The secret lay in the composition of the team. They all had a lot of experience of working together on large research projects and they all brought the same professional attitude and saw each other as equals. In addition to the metaphor of the kitchen team, Dr. Bossy also brings music into play: "We see ourselves more as an orchestra that plays all the instruments and players correctly instead of a bunch of soloists." Applied to ProLMD, Bossy's statement means that the right composition of the consortium and a coherent research plan are key to the success of the project. The Fraunhofer ILT as research partner, various companies along the value chain from automation, laser and measurement technology as well as users from the automotive and aerospace sectors gave the consortium the right mix for the forward-looking project work. As project coordinator and later system provider, KUKA Industries from Würselen played a key role in the targeted research work.

Adjustment of the component in the inert gas cell of the ProLMD system. This installation is also located at KUKA in Würselen Project supervisor Stefan Scherr agrees. The graduate engineer is responsible for "Additive Manufacturing - ProMat_3D" at the KIT project management organization. He praises the cooperation and the project.

Adjustment of the component in the inert gas cell of the ProLMD system. This installation is also located at KUKA in Würselen Project supervisor Stefan Scherr agrees. The graduate engineer is responsible for "Additive Manufacturing - ProMat_3D" at the KIT project management organization. He praises the cooperation and the project.

Experts generally agree that Germany is a world leader in the field of metallic 3D printing. The ProLMD project should also help to maintain or even expand this position. Schleifenbaum: "I believe that we are actually in a good position in Germany, but we are also facing massive competition. With projects such as ProLMD, we can repeatedly make individual, very well-placed and also very painful pinpricks for the competition.

Helmut Bossy adds: "We have a good research landscape and project funding. It's now a matter of keeping at it. It is important to maintain our leading position. For example, I see the build-up welding of difficult-to-process materials such as special types of steel, nickel-based alloys or titanium as a positive development. Companies are now gaining more and more confidence and are able to introduce their respective product and production portfolios to additive technologies on a broad scale. And the ProLMD project, as well as twelve other projects, have provided a good boost. The subject area is called ProMat_3D."

Not only did the composition of the team contribute to the success, but the environment on the Aachen RWTH campus also proved to be not unimportant. Some of those involved even claim to have detected a hint of Stanford and Silicon Valley. RWTH Aachen University is celebrating its 150th anniversary this year under the motto "Learning. Research. Do". Aachen makes many things possible by offering space, land and research infrastructure to attract companies. There are now more than 400 enrolled companies on the campus alone that are working together to develop, research and shape the future - a European "Engineering Valley". What will happen next with the project? What would ideally come out of it? Günter Neumann has clear ideas. He hopes that the findings can be used to put together a package for customers in which the features are "ready to use". That is still rare these days. Entrepreneurs can put a lot of things together, but it is still difficult for them to buy everything from a single source. Close cooperation with institutes makes this possible. The ultimate goal is something like a general supplier for additive manufacturing.

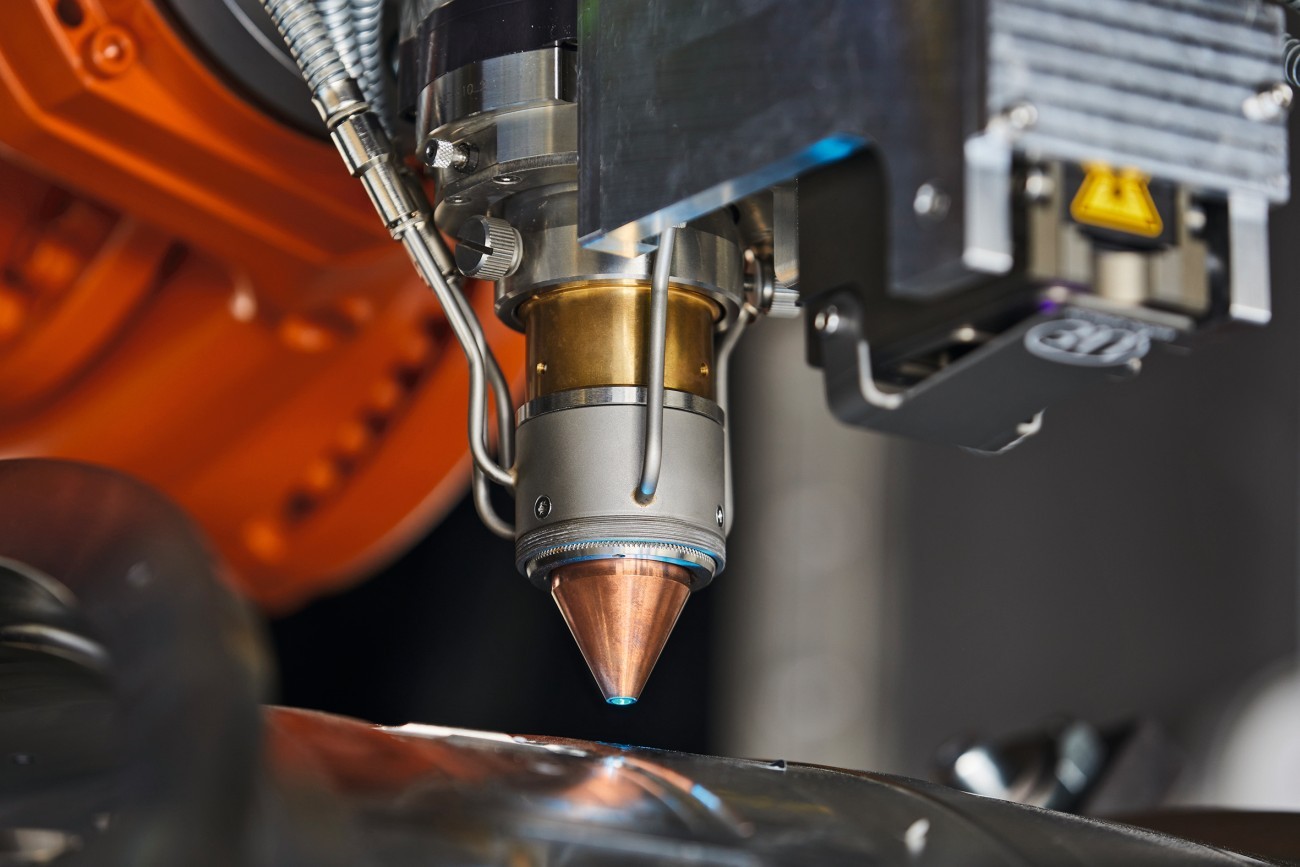

Powder nozzle for laser cladding in the shielding gas cell of the ProLMD system

Powder nozzle for laser cladding in the shielding gas cell of the ProLMD system

The BMBF intends to continue funding such future-oriented projects. Users, especially in additive laser manufacturing, also need a basic knowledge of how to handle materials and the technical requirements. And, of course, to introduce artificial intelligence methods into production and spread them further there. The team in Bonn is currently analyzing and evaluating the sketches received in this regard. Incidentally, the BMBF also invited the additive manufacturing community to submit proposals. Bossy: "I see artificial intelligence as a good approach to making planning and production processes more stable and controllable."