The technology of war

For over a year, we have been witnessing the horrors of war in Ukraine. Now there is also war in Gaza and Israel. These pages are not the place to talk about such tragedies, apart from mourning the many tens of thousands of innocent civilians who have lost their lives. But - whether we like it or not - war is about technology, and Germany, like the US, France and the UK, is a major manufacturer of military equipment, from Leopard tanks and fighter jets to ammunition. And our industry plays its part in these industries as an electroplating and surface technology provider. The US, China and NATO countries are not directly involved in these conflicts - but they are watching them closely and drawing lessons from them.

The war in Ukraine has been fought largely conventionally, and both sides have used Soviet-era tanks, some of which are almost antiques, such as the T62, which was first launched in 1961. The T72 is not much younger, having first entered service in 1969. The Shaheed drones manufactured in Iran are relatively simple devices and, with a unit price of around 25,000 US dollars each, quite inexpensive. For reasons that are unclear, Russia has hardly deployed any of the most modern T14 Armata tanks. Whether this is because it does not have many of them, or because it fears that they could be captured and examined by NATO, we do not know. Russia is also deploying a number of missiles, including the Kh-47M2 Kinzhal hypersonic missile. At least some of these missiles have been destroyed by the US Patriot missile defense system.

The conflict in Israel is quite different. Israel has developed some of the most advanced military equipment in the world. The Merkava family of tanks (series 1 to 4) is unique in that the engine is located in front of the tank to protect the crew. Israel is now developing a successor, the so-called. Karmel. Hamas has developed the "Al-Yassin" anti-tank missile, whose 105 MM shell has reportedly destroyed an Israeli tank in recent weeks. Israel also developed the so-called. "Iron Dome", a coordinated system that detects incoming missiles and fires anti-missiles to destroy them. Iron Dome has proven to be extremely successful in recent years. However, it has two weaknesses. The first is that it can fend off perhaps a hundred incoming rockets. But sometimes Hamas sends out up to a thousand drones or rockets, and then the Iron Dome is overwhelmed by the sheer number. It takes time for the rocket launchers to recharge. The second problem is that each anti-missile costs about 60,000 US dollars, while some of the Hamas missiles only cost about 600 US dollars. Israel is currently developing a radical new laser-based defense system known as the "Iron Beam". Each "shot" will cost only 3.50 US dollars. According to the Israeli authorities, the 100 kW system has already been successfully tested and never needs to be recharged. However, such laser-based systems work less well in cloudy or rainy conditions. Israel has also developed a new missile defense system called "SkyCeptor". It is described in detail at:

www.rafa el.co.il/wp-content/uploads/2019/03/SkyCeptor-Brochure-2.pd

Conclusion: Weapons technology is in a constant state of flux. We in Europe are lucky enough not to be involved in a war at the moment, but if we don't learn from Ukraine and Israel and modernize our military, we could one day pay a high price.

Amazon on the rise

Not everyone loves Amazon, but it's a fact that the company - unlike any other supermarket or department store - invests hundreds of millions of dollars in research and development every year. In recent weeks, it has announced two new projects. In a few weeks, the company will start delivering orders by drone in the UK. The service is limited to shipments weighing less than 2.25 kg. However, there are two problems. Sometimes technological developments can overtake existing regulations. The current rule in most countries is that drones may only operate within the operator's "line of sight". This limits their range to 2-3 km. This regulation is now slowly being relaxed. In Belgium, the use of 6 drones to monitor the 120 square kilometers of the port of Antwerp has been approved

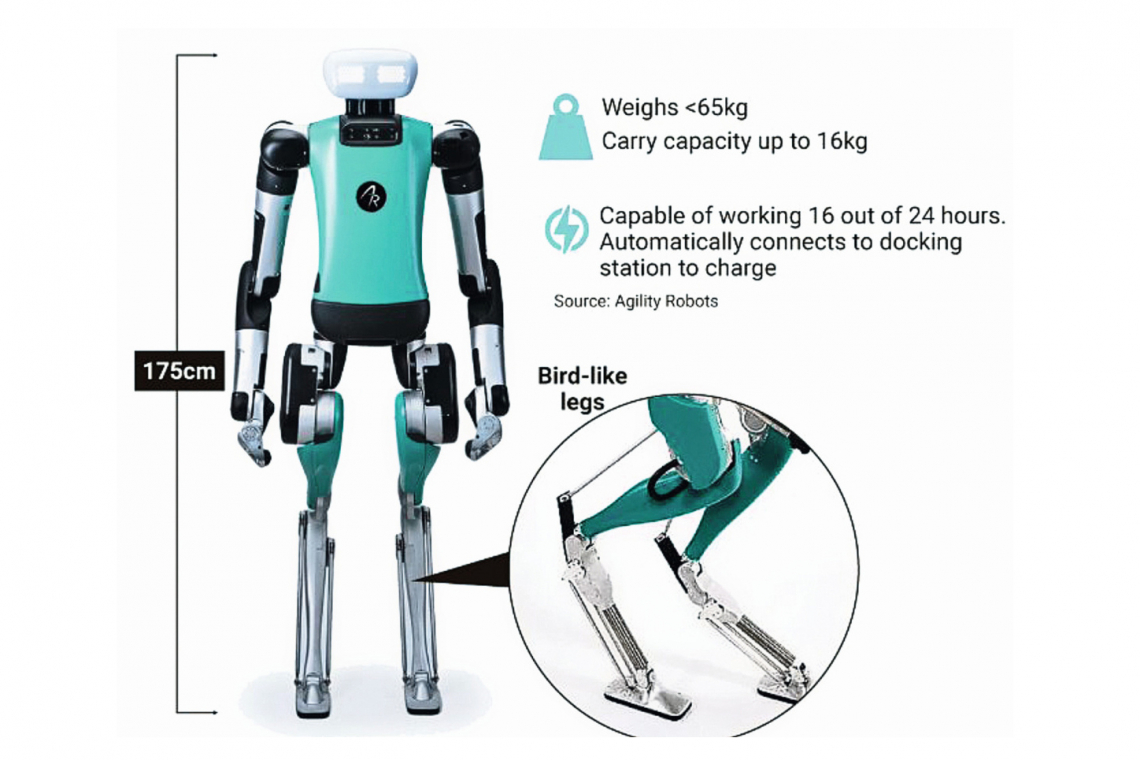

outside the line of sight of their operators. Similar permits have been granted to the delivery company UPS in Florida and South Carolina. In England, six trials are underway for drones flying beyond the line of sight. And the second problem? What about those who live in an apartment building? There are predictions that drones could create up to 650,000 new jobs across Europe by 2030 in industries such as construction, agriculture and logistics. The other news from Amazon concerns initial trials with the new robot "Digit" (Fig. 1).

The new design of human-shaped robot, which can lift and move items, is being tested in Amazon's Seattle warehouse as the e-commerce company looks to increasingly automate its fulfillment process. Initially, the robot is being taught to pick up and move empty boxes to ensure they are ready for reuse. The yellow boxes or bins are used throughout the online fulfillment process, from picking items to packing. However, according to Tye Brady, chief technologist at Amazon Robotics, there are many more uses for the robot. The robots were developed by Agility Robotics(https://agilityrobotics.com), an Oregon-based company that Amazon backed through its $1 billion Industrial Innovation Fund, a venture capital vehicle. Currently, empty boxes in warehouses without conveyor belts are moved manually by employees on a trolley. Digit is 175 cm tall and can transport items weighing up to 16 kg. It can work 16 hours a day, which is equivalent to the working hours of two full-time employees. Digit's ability to walk on two legs could be particularly useful for Amazon. A walking robot indicates that Digit's human-like form is not entirely accidental. It was developed to work in an environment suitable for humans. According to Agility's website, it is able to use its arms and legs and regain its balance when pushed. However, the robot is not yet able to perform all the necessary tasks, such as identifying certain objects.

Amazon explained that the robots have been designed to work alongside employees. However, with the company increasingly relying on automation in its facilities, the question is what impact the increasing use of robots will have on the number of jobs. Brady dismissed claims that increased use of automation in Amazon's warehouses would mean fewer jobs. Instead, Brady said, the robots would free up employees to take on more nuanced tasks that require logic and reasoning, as well as make facilities more efficient and potentially bring cost benefits to customers. "When we do that, we're more productive and can create more jobs because there's more demand." In Houston, Texas, Amazon is developing another robotic system, "Sequoia", which can stack boxes. Amazon now has 750,000 robots in use at its facilities worldwide. By comparison, the company employs 1.5 million people worldwide. The two figures are not all that different. There is growing concern among the Amazon workforce that jobs will be lost as a result of increasing automation. The company's management denies that this will be the case. Only time will tell! But while Amazon is increasingly automating, the precarious situation of traditional department stores remains. Not a healthy situation.

Global warming

We all know that climate change is causing temperatures to rise around the world. Not so many of us know that another effect of climate change is that turbulence in the air is increasing. As a result, air passengers today are increasingly experiencing a "bumpy flight" that is sometimes uncomfortable and sometimes even dangerous. This was confirmed in June this year by a report from the University of Reading and the UK Meteorological Office, which concluded that bumpy flights are becoming more common due to warmer air caused by climate change. The study found that the skies are becoming more prone to turbulence - officially defined as conditions that generate a force of at least 0.2g - and that the biggest increase in the last 30 years has been on transatlantic flights. The effects are most severe in free-air turbulence, which occurs unexpectedly (unlike a storm, which can be seen visually or on radar) and is more difficult for pilots to navigate around.

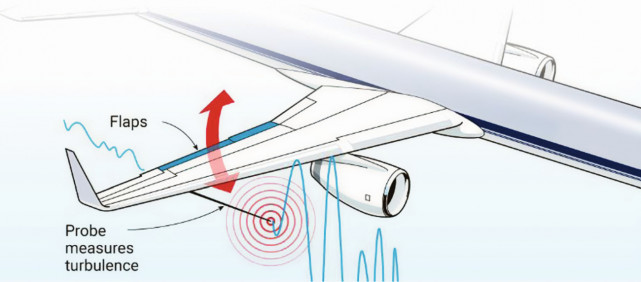

Austrian András Gálffy, founder of the Austrian-based company Turbulence Solutions, has found a possible solution. He has developed a system designed to prevent turbulence - an ambitious goal that is already being used in a two-seater aircraft in Europe and is due to be officially introduced at the beginning of 2024. As a licensed pilot who has been flying for more than ten years, Gálffy noticed the increasing turbulence he felt when flying through Austria with his friends and wanted to do something about it. Although turbulence is not dangerous, he admits that it makes the flight uncomfortable for passengers and makes them increasingly afraid of flying. The basis of his "Turbulence Cancelling Technology" is to create a counter-current to stabilize the movement of an aircraft. It does this by attaching small, fast-acting flaps to the wings that generate vertical lift when air turbulence pushes the aircraft downwards. The technology quickly adjusts the shape of the wings to deflect the airflow so that the wind flows past the wings without affecting the movement of the aircraft. According to Gálffy, the principle is similar to noise abatement. "We create a counter-turbulence to counteract the movement and this simply cancels itself out". The system is illustrated in Figure 2, which shows a 1 m probe that extends forward from the leading edge of the wing, detects changes in air density and sends a signal to a flap on the trailing edge of the wing. Fig. 2: Turbulence suppression technology

Fig. 2: Turbulence suppression technology

Currently, the new technology is being used in a small aircraft, but the first goal is to extend the technology to light aircraft, as these suffer the most from turbulence and cannot escape it because they fly lower. Gálffy has founded a company, Turbulence Solutions(https://turbulence-solutions.aero), and we wish him every success.

On the way to a greener world

Much has been written about new green energy sources such as wind turbines and solar panels. But it is becoming increasingly clear that we do not have enough capacity in the high-voltage grid to connect these new energy sources to the national grid. There seem to be two different problems. Firstly, the legal procedures required for the erection of high voltage pylons. And secondly, the huge amount of new cables that will be required. According to a new analysis by the International Energy Agency (IEA), power cables long enough to reach 200 times from the Earth to the Moon will need to be built worldwide by 2040 to meet countries' climate targets. The IEA warned that the transition to clean energy could be jeopardized if the approximately 70 million kilometers of new and replacement power grids cannot be built over the next two decades. To achieve this, investment in electricity grids alone would have to more than double to 600 billion dollars per year by 2030, according to the IEA. The IEA warned that grid constraints could become a bottleneck in some areas and called on policy makers and companies to "act quickly" to solve this problem. "We need to invest in the grids today, otherwise we face gridlock tomorrow," said Fatih Birol, Executive Director of the agency. The IEA was founded in 1974 as a forum for cooperation in the energy sector to ensure secure access to oil supplies. The remit of the Paris-based organization has expanded to include advice and analysis of the wider global energy system. Almost 70 million kilometers of overhead or underground cables are in use worldwide, comprising both high-voltage and low-voltage distribution networks. According to the IEA, as the world seeks to reduce emissions to avoid the worst effects of climate change, electricity will play an increasingly important role in the energy system, requiring "bigger, stronger and smarter grids". Electric vehicles and heat pumps are increasing demand for electricity, while countries are building new wind and solar farms that need to be connected to the grid. The IEA estimates that more than 45 million kilometers of new lines will need to be built and more than 25 million kilometers of existing lines replaced and modernized by 2040 based on the countries' announced energy and climate pledges. Grid expansion is already not keeping pace with the expansion of renewables, and delays in grid expansion have become a major problem in the UK energy industry, with a huge queue of projects of more than 250 GW waiting to be connected to the grid and new transmission lines a decade or more away. This is a huge opportunity for the German industry - a guaranteed market!

Vision for the future - or a return to the past?

In recent weeks, a new bulk carrier has set sail - the "Berge Olympus". She is the newest member of Berge Bulk Reederei's 80-strong fleet with a total carrying capacity of 14 million tons. Last year, Berge's ships transported around 70 million tons of steel, ore and other bulk goods all over the world. The Berge Olympus (Fig. 3), a bulk carrier, is actually five years old, but was refitted in a Chinese shipyard a few weeks ago. It is 300 meters long and has a carrying capacity of 211,000 tons. As part of the retrofit, the Berge Olympus was equipped with four BARTech wind wings from Yara Marine Technology(https://yaramarine.com). Each wind wing is 37.5 meters high and 20 meters wide and has a total area of 3,000 square meters. The wind wings are expected to save 6 tons of fuel per day. The ship is also equipped with a 1 MW diesel generator. It will initially sail between Brazil and China, a route where winds are normally favorable. Fig. 3: The Berge Bulk ore carrier, newly equipped with "WindWings "

Fig. 3: The Berge Bulk ore carrier, newly equipped with "WindWings "

The Berge Olympus is a bold experiment, but it is not the first for this shipping company. Last year, the company signed a contract with Anemoi Marine Technologies(https://anemoimarine.com) to equip two large ore carriers with wind rotors. The first is the Berge Neblina with a carrying capacity of 388,000 tons and the second is the Berge Mulhacen with 210,000 tons. The Anemoi technology is of particular interest to German readers interested in history. Take a look at Figure 4, which shows the two ships as they will look when they are equipped with Anemoi technology. It is an almost exact replica of the German Flettner rotor technology from the 1930's. Berge Bulk is undertaking a bold experiment with these three ships. It will soon be exactly 100 years since Anton Flettner launched his experimental ship "Buckau" in 1924. So history is repeating itself. Will this new/old technology be more successful this time? we will have to wait and see.