The reference project presented below shows how the investment in a modern drying system pays off in terms of process and quality costs. The investment pays for itself after just a few years thanks to the increase in product throughput, energy savings, lower heating output and state subsidies.

By investing in a modern drying system, a production company from the European Economic Area saves around 80,000 kWh per year in energy consumption. The new GALVADRY® drying system was designed as a space-saving two-chamber dryer. In addition to saving energy, this allows up to 50 % higher load capacity

Criteria for an efficient drying system

The primary aim of plant operators is to improve production output through short drying times and perfect drying results. As a rule, the required quality requirements and throughput rates cannot be achieved with older drying systems: Dryers from other technological eras require long and energy-intensive drying times. Long drying times and a lack of control and regulation functions lead to process-related restrictions (cycle time, throughput) and possibly quality problems due to coating abrasion. As a result, drum batches cannot be treated in a product- and quantity-optimized manner. Fabric drying can only be achieved with longer cycle times and/or higher temperatures.

Modern drying systems offer an immediately measurable improvement in efficiency and quality. The criteria are: Short drying times, high throughput and a high degree of flexibility in the range of goods to be treated and low maintenance and servicing costs. This is achieved through intelligent energy management of the program control, thermal insulation without thermal bridges, sophisticated flow control, combined with a low-maintenance, efficient heat recovery system.

Energy saving subsidized by the state

In today's environmentally conscious "Green Deal" era, there are of course also sustainability goals: modern, highly efficient drying systems make a major contribution to energy savings, which are also verifiable. Considering that dryers in a barrel plating plant are in use for more than 30 years on average, annual energy savings of 20-30% quickly become significant - and ensure that the dryer investment pays for itself after just a few years. Government subsidies for energy-saving technologies also have a positive effect on amortization. The maximum subsidy in Germany is up to 40% of the eligible investment costs (as of July 2021). This means that every ton ofCO2 saved is subsidized with an amount of 500 euros. For small and medium-sized companies, the amount is even 700 euros. Due to the high savings achieved by a new drying system, a considerable proportion of the investment sum is immediately reimbursed by the state.

Reference project

Hot air dryers had been in use for 25 years in an electroplating plant of a production company in the European Economic Area. The dryers were preceded by a hot rinse, which was operated at 60 °C. The goods were therefore preheated. The goods were therefore preheated and then dried at 80 °C. In order to achieve complete fabric drying, cycle times of > 10 minutes were required and the drum fill quantity even had to be reduced for fabric with a high carry-over rate. With the procurement of spare parts also becoming an increasing challenge, the company decided to invest in a modern drying system.

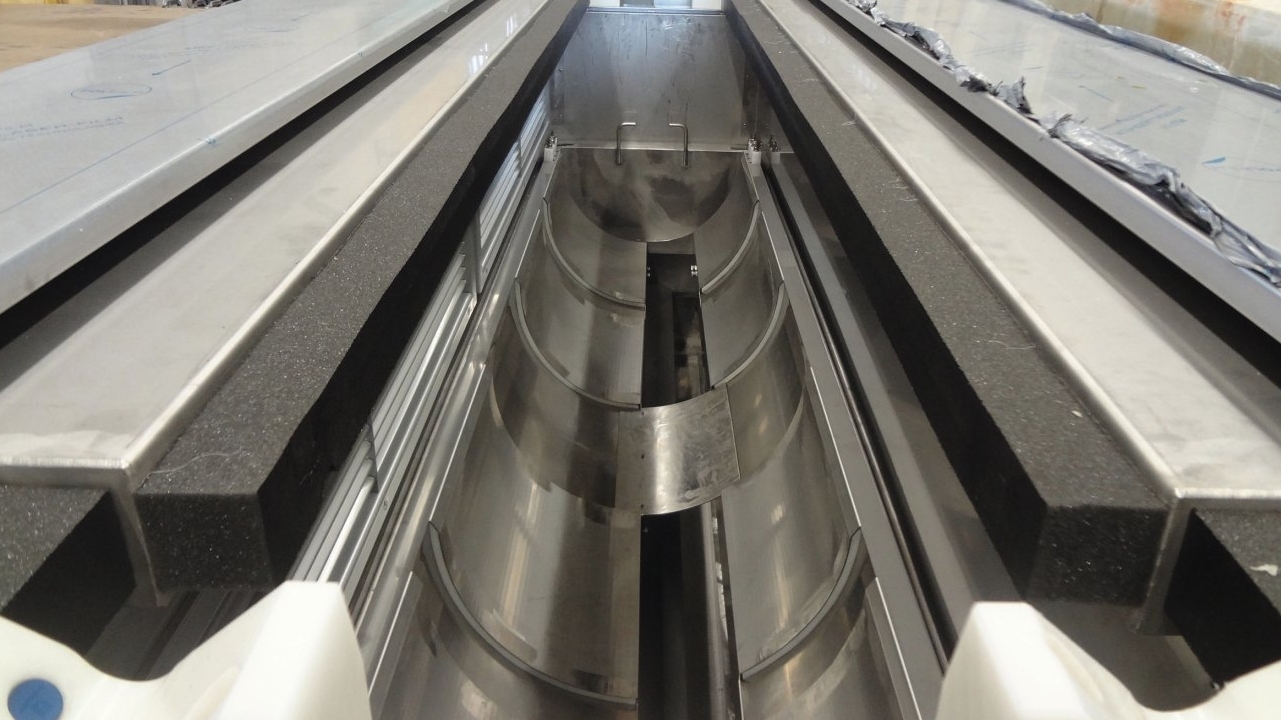

Two-chamber drum dryer

After weighing up the systems available on the market, the decision was made in favor of the GALVADRY® dryer from Richard Tscherwitschke GmbH, which was commissioned as a space-saving two-chamber drum dryer with integrated energy recovery and a self-sufficient control and regulation system. With this solution, it was possible to achieve the lowest possible energy consumption and space requirement while at the same time increasing the productivity of the system. The results in the test dryer were convincing in terms of process parameters, reliability and quality. The new dryer solution has been in operation since 2019.

Productivity gains thanks to improved drying parameters

While the old dryer was previously only able to achieve a throughput of 100 kg of goods per drum unit at maximum capacity and with an upstream hot rinse, the modern drying process of the GALVADRY® now enables a 50% higher load of up to 150 kg. Energy is also saved: the drying temperature is now only 50 °C on average. The upstream sink is only operated at room temperature and no longer needs to be heated. The special air routing in the drying chambers accelerates drying, while the thermal bridge-free insulation ensures a high degree of utilization of the energy used.

The integrated PLC regulates the temperature, drum rotation, air flow and energy supply by continuously measuring the moisture level. This achieves optimum, product-specific drying results with minimum energy consumption.

80000 kWh saved per year

Thanks to the energy-saving drying process with integrated energy recovery, an average of 25 kWh was saved per machine hour in this project. At average capacity utilization, the annual saving is therefore over 80,000 kWh.CO2 emissions are reduced by approx. 40 tons (according to the German electricity mix). Depending on the electricity tariff, this can save around 25,000 euros per year. In the reference project presented here, the cost savings are currently around 30,000 Swiss francs per year. The investment in the GALVADRY® drying system and the associated energy savings were also rewarded with a state subsidy amounting to 30% of the investment sum.

Low maintenance cycles

Another aspect that should not be underestimated when modernizing systems is the ease of use and low maintenance cycles of the new GALVADRY® dryer models. Thanks to the modernization, the maintenance requirements of the drying system have been significantly reduced. In principle, the filters are the only wearing parts. Maintenance personnel can replace the filters themselves. The drying process takes place via the integrated control system, which communicates with the system control via a bus system. Fabric-dependent control parameters can thus be entered directly via the system control. The GALVADRY® has a display for maintenance and diagnostic purposes as well as for test runs with new fabric. This can be used to call up diagnostic data and set drying parameters such as temperature, drum rotation and control settings for energy recovery directly.

Dryer with integrated energy recovery

Richard Tscherwitschke GmbH is the market-leading manufacturer of electroplating drums and units and has been building its own drum dryers for surface treatment systems for 40 years. The drum and drying technology are ideally matched, for example in terms of air flow, air volume control and gentle drum movement. The focus here is on the individual adaptation of the drying system to customer requirements, optimum design and the greatest possible energy savings. To this end, drying tests are carried out for customers at the Richard Tscherwitschke GmbH test center. The results are used to design the drying system and provide certainty for planning and investment.