Even today, polishing free-form surfaces on tools, mold inserts or similar components is usually still a manual, time-consuming process. Employees with the right skills and stamina for these tasks are rare, and it is often not possible to reproduce them in large-scale production. The patented Surfast technology from Jet Clean Systems can automatically polish a wide variety of metals or plastics, depending on the additive and pressure used.

Jet Clean Systems was formed in 2015 as a management buyout during the merger of General Electric and Alstom. From 2007 to 2015, the technologies now used by Jet Clean Systems were developed, applied and verified in research projects. Today, by using this technology, a surface quality with Ra values of less than 0.1µm can be achieved depending on the initial surface. With the Surfast system, several work steps become one, which saves an enormous amount of time and money. The method and the associated systems are currently marketed by industry expert Michael Hofer of MostTech, among others.

Efficient technology for the post-processing of 3D printed components

Especially when using manual processing steps, post-processing in additive manufacturing often takes up 60% of the total manufacturing time and therefore represents a decisive cost factor. For extremely small, but also very large components, manual processes can be replaced by automated fast processes. Several work steps can be turned into a single one.

Especially when using manual processing steps, post-processing in additive manufacturing often takes up 60% of the total manufacturing time and therefore represents a decisive cost factor. For extremely small, but also very large components, manual processes can be replaced by automated fast processes. Several work steps can be turned into a single one.

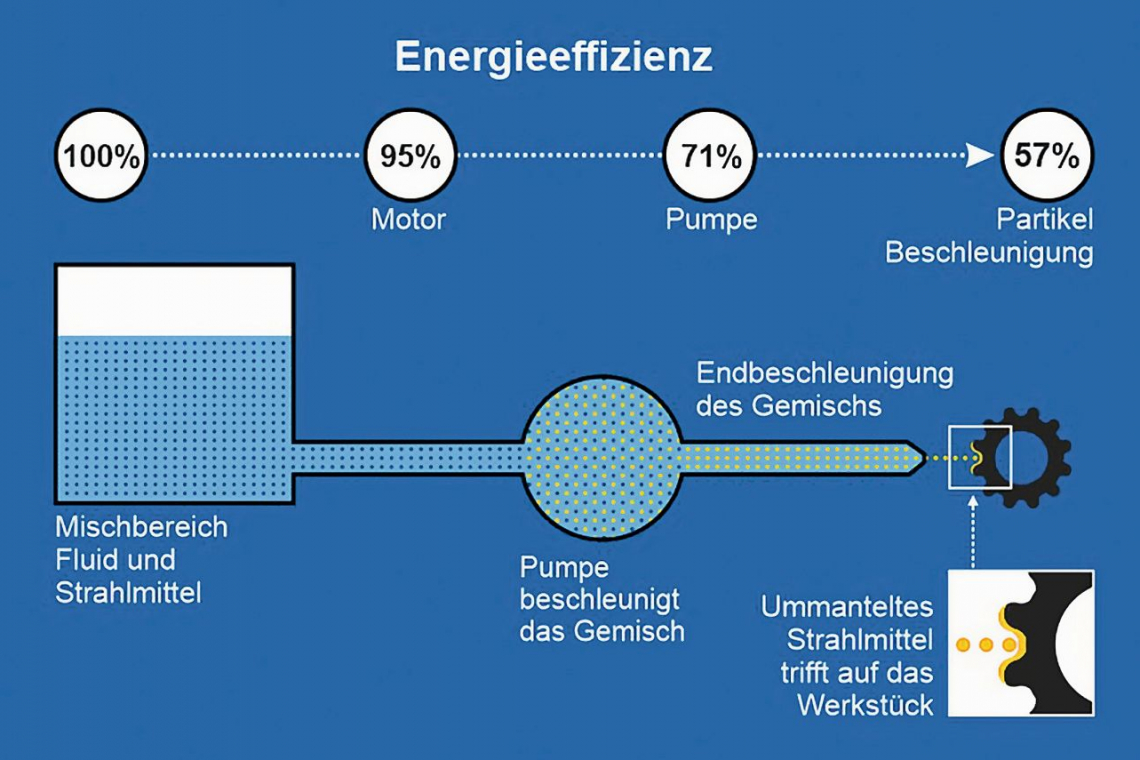

Surfast technology basically involves mixing abrasive additives and the fluid at ambient pressure to begin with. The mixture is then brought directly to the desired working pressure by a pump. This creates an abrasive jet with an overall efficiency of 57 %. This enables efficient processing of components and surfaces made of metal and plastic. The significantly higher overall efficiency of the Surfast technology results in lower energy consumption.

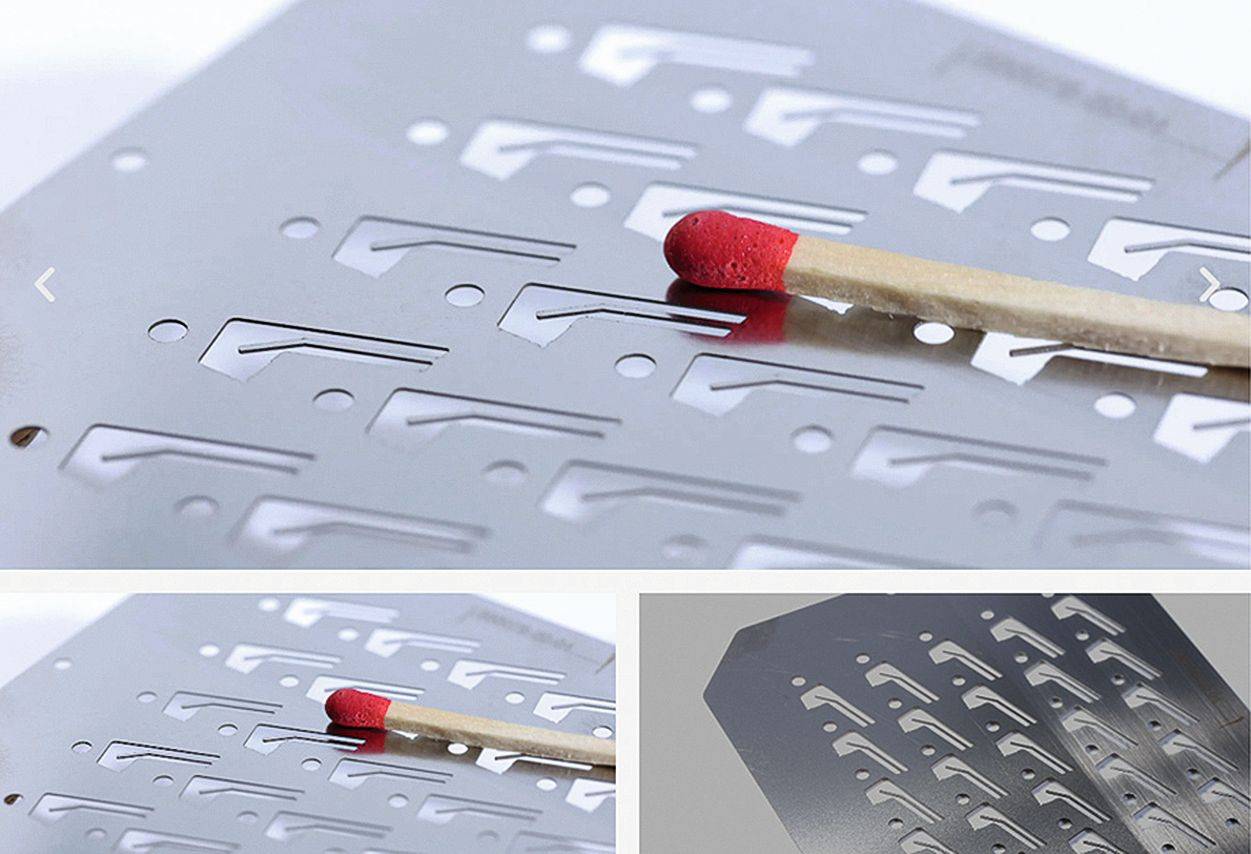

The abrasive blasting media are coated with fluid and are located in a circulation system. This means they can be used for much longer. Depending on the composition of the blasting medium, the mixture of different media and the setting of the blasting parameters, surfaces can be processed flexibly. The working area ranges from gentle polishing and deburring to targeted roughening of surfaces. Even intricate contours and lettering can be processed and an attractive appearance achieved. This is made possible by the particle coating created during premixing, which produces a certain damping effect. This parameter can be varied in a targeted manner, which leads to increased flexibility in component processing.

Versatile application possibilities

Surfast can be individually adapted to the respective application using its own components. From standard blast cabinets and filter units to fully automated, robot-controlled processing environments for efficient and reproducible surface processing.

Turned, milled, drilled or eroded production parts made of metal and plastic from 1 mm to several meters can be cleaned in this way. Cutting edges are cleaned without rounding off the corners. Deposits can also be removed from tool inserts. This even works in channels, i.e. on internal surfaces. The processing of molds, injection and die casting tools as well as embossing dies is therefore one of the main areas of application of the method.

The surfaces of implants must also be brought into a suitable surface condition for the application after basic machining. It is precisely in this area that the method shows its strength. In the manufacture of medical implants or bone plates and precision tools, the surfaces can be processed without changing the geometry. No residues remain on the surface.

In the production of components made of metal, sheet metal and plastic, burrs often occur at transitions, which must be removed for precise use or before further processing. Due to the increasingly complex component geometries, these can usually only be removed in a downstream manual process (e.g. brushing). The automated Surfast system ensures the tightest tolerances and efficient deburring at the same time. There is no unwanted edge rounding. Components with internal geometries and cross holes can be deburred just as easily as complex external geometries. Processing of bulk material is possible.