Fillserts are selectively open-pored aluminum inserts for the production of lightweight, high-performance, multifunctional, media-tight hybrid parts for mechanical, electrical, mechatronic, thermal, optical, chemical and many other applications. In contrast to conventional metal inserts, the fillserts have previously unknown multifunctional and multi-structural properties and are infiltrated rather than overmolded with plastics.

The fillserts offer many innovative approaches to increase the material, energy, resource and cost efficiency of products. They are available in three- to six-digit quantities in various designs. Interested companies can take advantage of free consulting services.

Insert and outsert technology

The production of hybrid components by combining plastics with metals has long been established in plastics processing. There are two main processes for this: In insert injection molding, the functional properties of metallic materials are integrated into the plastic matrix in the form of inserts. The metal inserts are inserted into the master mold during the production process and are almost completely overmolded by the primary molded plastic in a force-fit and form-fit manner.

In outsert injection molding, the functional properties of polymer materials are integrated by selectively encasing a metal insert. In this case, the metal inserts are only overmolded by the primary molded plastic in selected areas.

However, both hybrid techniques have well-known disadvantages, especially for modern, function-integrated lightweight construction:

-

Use of heavy metals such as steel or brass

-

Small contact surface with limited force and form fit

-

Warping, cracking and leakage due to different thermal expansion

-

Increased risk of crevice corrosion, contact corrosion and electrochemical corrosion at the interfaces between different materials

-

Limited quality and functionality when transmitting higher forces and torques, especially in the event of vibration or climate change

-

Partial need to use chemicals for better adhesion

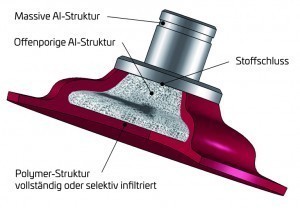

Fig. 2: Fillserts combine structures, materials and functionsTheworldwide new fillsert technology improves hybrid parts in terms of weight, performance, multifunctionality and quality and enables previously unimaginable designs and applications.

Fillserts are produced as selectively or completely open-pored cast parts made of aluminum using the gravity die casting process. They have solid and/or open-pored functional areas that are bonded together. The possible geometric combinations of open-pored and solid functional areas allow many new design solutions.

The open-pored chill-cast parts differ in all aspects from conventional foamed or sintered metals. They have adjustable pores, macroscopically isotropic properties, a resilient cast structure, better mechanical, fluid-mechanical, thermal, acoustic and other properties and can be manufactured in different shapes and sizes to an accuracy of a hundredth of a millimeter. The density of open-pored aluminum is approx. 1.3 g/cm3.

All functions known from solid metals, such as threads, drill holes, hinges, eyelets, press-fit bolts, rivet nuts and much more, can be realized in both the solid and the open-pored functional areas of the Fillserts.

Fig. 3: The geometrically precise and macroscopically isotropic fillserts can be excellently integrated into the plastic matrixThepore size in the open-pored functional areas can be adjusted from a few micrometers to several millimeters depending on the application, and graded settings are also possible. They can be infiltrated with polymers in various primary molding processes such as injection molding, thermoforming, blow molding, foaming or RTM to produce an extremely strong, gas-tight material composite without the use of chemicals. If they are deliberately not infiltrated, they can integrate other functions specific to open-pored metals such as filtration, sound absorption, heat transfer, crash energy absorption, ventilation and much more.

The completely open-pored fillserts without a solid functional area can be fully integrated into a plastic matrix. This means that a plastic component can be deliberately equipped with functionality from the composite material at selected points.

The selectively open-pored fillserts can be equipped with one or more solid and/or open-pored functional areas to enable many other combinations of solid, open-pored, infiltrated and non-infiltrated functional areas.

Fig. 4: The examples give a first impression of the new design possibilitiesThesolid fillserts with selective, open-pored functional areas can be infiltrated locally with polymers. In this way, an aluminum component can be deliberately equipped with a functionality from the composite material at selected points or provide a defined interface for a plastic component.

Fastening fillserts - hybrid fastening systems for material hybrids

The Fastening Fillserts are hybrid fastening systems for multifunctional multi-material use. They are based on the excellent compatibility of open-pore castings with conventional joining methods such as screwing, riveting, flanging, press-fitting, soldering, gluing, ultrasonic welding, etc. This provides very flexible options for developing an optimum fastening system for every application. Such interfaces can also be equipped with additional functions such as vibration damping, filtration, heat transfer and more.

For example, the ecosyn® blind rivet nut technology developed by KVT-Fastening Deutschland GmbH for plastics and lightweight materials, among other things, is also impressive in open-pore cast parts. Due to the specific design of the fastening element, a defined bead formation is achieved here without perforation in the base material. This ensures both a secure fit of the thread system and ideal tolerance compensation. Even thin-walled areas and hollow structures can be used for load-bearing fastening points.

Fig. 5: Fillserts as a hybrid fastening system in combination with ecosyn® blind rivet nut technologyTheFillserts with thread in the porous area are load-bearing and can be screwed to various porous or solid components. The deliberate infiltration of the porous thread with polymers or adhesives additionally secures the screw connection in the event of vibrations or dynamic, cyclical loads through a chemical or clamping locking effect.

The modern Fastening Fillserts combine classic fastening elements with the design freedom of porous castings to create new, hybrid, multifunctional and precise fastening systems. They can be pre-assembled, automatically inserted into the production tools and excellently infiltrated with polymers, resins, adhesives or similar.

Metaker® Fillserts: Enhanced performance and multifunctionality

In addition, the functionality and performance of Fillserts can be further enhanced by converting the surfaces of the component in the solid and/or open-pored functional areas into a high-performance, multifunctional micro-material composite using the Metaker® process.

Fig. 6: Load-bearing screw connection between an open-pored Fillsert and a solid material nozzleTheMetaker® Surface Technology changes the mechanical, electrical, thermal, optical, haptic, chemical, biological and other material properties of light metals. Depending on the individual configuration, Metaker® Fillserts can be equipped with many functions that were previously impossible for aluminum, making the use of steel, brass, bronze or ceramic superfluous:

- Thermally conductive, microstructured and extremely wear-resistant → Tribology, thermal management

- Dielectric (22 kV/mm) and extremely thermally conductive (210 W/mK) → Electronics

- Microstructured, microporous, extremely wear-resistant → Tribological boundary layers, lubrication

- Extremely heat-conducting and extremely heat-radiating → IR heating, LED and electronics cooling

- Thermally conductive, corrosion-resistant and light-reflecting → Lighting systems

- Optically and haptically sophisticated, scratch-resistant, light-absorbing → Decorative parts, optical devices

- Atomically adhesive, microstructured, microporous and activated → Bonding, printing, painting, impregnating

- Food-safe, microstructured and bioactivated → Medicine

- And much more.

For example, a Metaker® modified 99.5% aluminum fillsert can have a surface microhardness of over 1000 HV, a dielectric strength of 22 kV/mm and a thermal conductivity of 210 W/mK. The range of functions that can be implemented and the resulting potential are enormous.

Fillserts - advice and system solutions

In order to exploit the full optimization potential through the use of fillserts, a holistic understanding of the technology is required in the interdisciplinary development teams. Automoteam GmbH offers interested companies free consulting services for their R&D teams.

In a further step, the fillserts can be adapted to specific applications in one of the standard versions or developed to series maturity in a special version. The developed solutions can be delivered in three- to six-digit quantities.

Fig. 2: Fillserts combine structures, materials and functionsTheworldwide new fillsert technology improves hybrid parts in terms of weight, performance, multifunctionality and quality and enables previously unimaginable designs and applications.

Fig. 2: Fillserts combine structures, materials and functionsTheworldwide new fillsert technology improves hybrid parts in terms of weight, performance, multifunctionality and quality and enables previously unimaginable designs and applications. Fig. 3: The geometrically precise and macroscopically isotropic fillserts can be excellently integrated into the plastic matrixThepore size in the open-pored functional areas can be adjusted from a few micrometers to several millimeters depending on the application, and graded settings are also possible. They can be infiltrated with polymers in various primary molding processes such as injection molding, thermoforming, blow molding, foaming or RTM to produce an extremely strong, gas-tight material composite without the use of chemicals. If they are deliberately not infiltrated, they can integrate other functions specific to open-pored metals such as filtration, sound absorption, heat transfer, crash energy absorption, ventilation and much more.

Fig. 3: The geometrically precise and macroscopically isotropic fillserts can be excellently integrated into the plastic matrixThepore size in the open-pored functional areas can be adjusted from a few micrometers to several millimeters depending on the application, and graded settings are also possible. They can be infiltrated with polymers in various primary molding processes such as injection molding, thermoforming, blow molding, foaming or RTM to produce an extremely strong, gas-tight material composite without the use of chemicals. If they are deliberately not infiltrated, they can integrate other functions specific to open-pored metals such as filtration, sound absorption, heat transfer, crash energy absorption, ventilation and much more. Fig. 4: The examples give a first impression of the new design possibilitiesThesolid fillserts with selective, open-pored functional areas can be infiltrated locally with polymers. In this way, an aluminum component can be deliberately equipped with a functionality from the composite material at selected points or provide a defined interface for a plastic component.

Fig. 4: The examples give a first impression of the new design possibilitiesThesolid fillserts with selective, open-pored functional areas can be infiltrated locally with polymers. In this way, an aluminum component can be deliberately equipped with a functionality from the composite material at selected points or provide a defined interface for a plastic component. Fig. 5: Fillserts as a hybrid fastening system in combination with ecosyn® blind rivet nut technologyTheFillserts with thread in the porous area are load-bearing and can be screwed to various porous or solid components. The deliberate infiltration of the porous thread with polymers or adhesives additionally secures the screw connection in the event of vibrations or dynamic, cyclical loads through a chemical or clamping locking effect.

Fig. 5: Fillserts as a hybrid fastening system in combination with ecosyn® blind rivet nut technologyTheFillserts with thread in the porous area are load-bearing and can be screwed to various porous or solid components. The deliberate infiltration of the porous thread with polymers or adhesives additionally secures the screw connection in the event of vibrations or dynamic, cyclical loads through a chemical or clamping locking effect. Fig. 6: Load-bearing screw connection between an open-pored Fillsert and a solid material nozzleTheMetaker® Surface Technology changes the mechanical, electrical, thermal, optical, haptic, chemical, biological and other material properties of light metals. Depending on the individual configuration, Metaker® Fillserts can be equipped with many functions that were previously impossible for aluminum, making the use of steel, brass, bronze or ceramic superfluous:

Fig. 6: Load-bearing screw connection between an open-pored Fillsert and a solid material nozzleTheMetaker® Surface Technology changes the mechanical, electrical, thermal, optical, haptic, chemical, biological and other material properties of light metals. Depending on the individual configuration, Metaker® Fillserts can be equipped with many functions that were previously impossible for aluminum, making the use of steel, brass, bronze or ceramic superfluous: