One of the main tasks of surface coating is to ensure the durability of products. Properties such as corrosion protection, hardness and friction coefficients are significantly improved by suitable coatings. However, if you leave this cosmos, you enter a world in which longevity is often undesirable.

One of the causes of the throwaway society in which we live is planned obsolescence, i.e. the deliberate reduction in the service life of products, e.g. by using inferior components

How does this fit together?

Once again, a complaint is on the table. A coating thickness of 8-12 µm was required, but the customer only measured 7.5 µm. "A complete 8D report is requested within three days." The in-house quality control department re-measures the parts. Although it does not reach 7.5 µm, the coating thickness measurement remains below the 8.0 µm mark. There can be many reasons for the insufficient coating thickness. In most cases, it has to do with the price pressure to which the electroplating shop is exposed. The 0.5 µm difference, if it is that big at all, makes no difference in 99.99 % of cases. Technically, everything is perfect. What some customers, perhaps from the automotive industry, are really interested in is pushing the price down further. At some point, an audit is due, everything is checked in detail - and new price negotiations follow later. These companies justify their complaints with quality and customer satisfaction. Longevity, in this case measured by the thickness of the coating, is seen as a quality feature. But in reality, it's all about the price!

If we zoom out from this individual example from the electroplating and surface technology sector and look at the topic in the context of society as a whole, durability was and is a critical factor. Using it as a cover for a price reduction, even though a slightly thinner coating thickness does not affect quality, is the least of the evils: some companies deliberately integrate weak points into their designs or block innovations in order to artificially reduce the durability of their products. Unfortunately, this is common practice and even has its own name: planned obsolescence, of which there are numerous examples in industrial history.

The Phoebus cartel set the lifespan of light bulbs at 1,000 hours to ensure their sale - Photo: stock.adobe.com/kimly

The Phoebus cartel set the lifespan of light bulbs at 1,000 hours to ensure their sale - Photo: stock.adobe.com/kimly

The Phoebus cartel

The practice of planned obsolescence has a long history. The definition of the Latin word obsolescence is: "The ageing of a product [in its method of manufacture, materials or similar], rendering it obsolete or unusable". A particularly well-known example of this is the Phoebus cartel, which was founded in the 1920s.

At the time, leading light bulb manufacturers noticed that the long life of their products was having a negative impact on their sales. Light bulbs that lasted a very long time meant that consumers were less likely to buy new ones, which depressed the companies' sales. To counteract this problem, several leading companies in the light bulb industry joined forces in 1924, including General Electric, Osram and Philips. They founded the aforementioned cartel with the aim of deliberately shortening the service life of light bulbs and thus increasing sales.

The cartel set a standardized lifespan for light bulbs of around 1,000 hours. To ensure that this target was met, they developed technical standards and test procedures. Companies that produced light bulbs with a longer lifespan were fined.

In the 1940s, the existence and practices of the cartel became public knowledge and were widely criticized. The public reacted indignantly to the deliberate shortening of product life. Although the cartel was eventually disbanded, it left a "lasting" legacy.

Super solid

A glass that never breaks? It already existed, but nobody in the West wanted to sell it. In the 1970s, scientists in the German Democratic Republic developed a particularly robust glass that became known as "Superfest" glass. This glass had outstanding properties. It was extremely break-resistant. The service life of the glass was about fifteen times longer than that of conventional glass.

The GDR used this glass in numerous areas, especially in public facilities and households. It was particularly popular due to its durability and break resistance. After the fall of the Berlin Wall, no Western company wanted to manufacture this product. In market-oriented countries, there was little interest in a product that was so durable that it impaired the sale of new products.

The "Superfest" glass is an example of the tensions between technological innovations and the economic systems in which they are introduced.

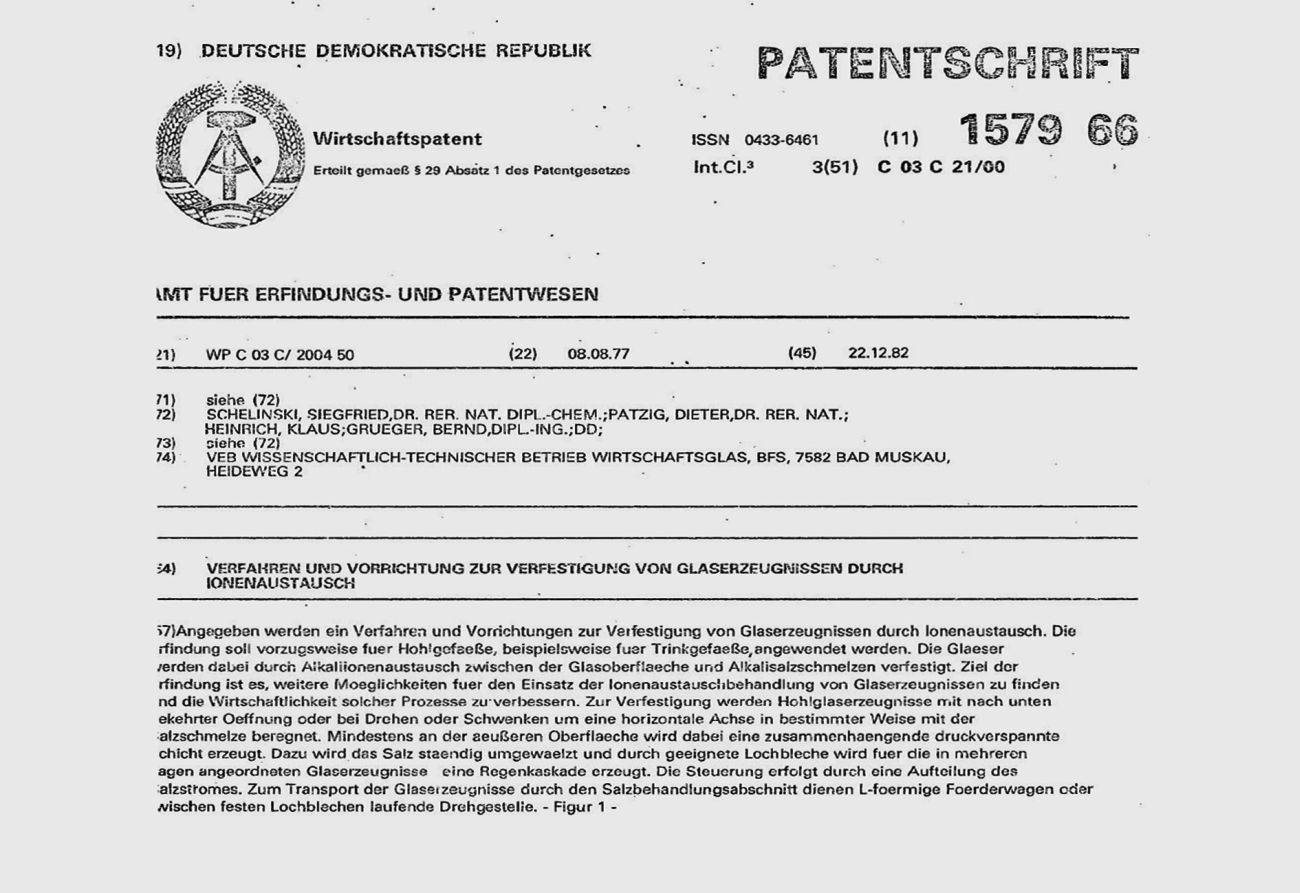

As this patent from the former GDR shows, super-solid glass requires a pressure-stressed layer on the surface of the glass - source: Wikipedia

As this patent from the former GDR shows, super-solid glass requires a pressure-stressed layer on the surface of the glass - source: Wikipedia

Virtually wear-free brake disks

It could reduce particulate emissions on the roads by 90% and last an entire vehicle life of 300,000 kilometers on average without requiring maintenance: the conventional grey cast iron brake disc, coated with tungsten carbide in a high-speed flame spraying process (also read the report from Galvanotechnik 9/2022, p. 1224 ff.). The patent has been around for decades. A foundry from Iron Valley in Hesse has been trying for several years to help the ultra-long-life brake disc, which has already won innovation awards, achieve a breakthrough, more recently with the development of a more cost-effective variant. However, commercial success has failed to materialize, even though the introduction of such a brake would protect the environment and save drivers a lot of money and effort. However, the victims would be the manufacturers, who would produce fewer brake discs, as well as the garages, which would have to service and replace fewer brakes in future - a mischievous person who thinks evil, although it is fair to mention that the introduction of such a braking system would bring further technical changes, because braking would be adhesive and no longer abrasive. At the same time, the issue of braking in electric cars must be viewed in a new light.

Modern times

Planned obsolescence is also common practice in the IT sector. A well-known example at Microsoft is the case of the early operating system "DR DOS", which was originally developed by Digital Research. Microsoft was accused of deliberately creating error messages in Windows 3.1 stating that the program would only run under MS-DOS, even though it technically also worked under DR DOS. These error messages caused confusion among users, prompting many to switch to MS-DOS. This practice was later the subject of a court case against Microsoft. In the meantime, Microsoft has adopted a slightly different company policy and is putting pressure on users to switch to the latest operating system version and preferably to a new PC with updates and the absence of updates.

Apple was accused of slowing down older iPhone models with software updates, especially when the battery was ageing. This led to a scandal and the so-called "Batterygate", in which Apple admitted to throttling performance to prevent unexpected shutdowns. However, critics argue that this encouraged consumers to buy new models instead of simply replacing the battery. Several class action lawsuits have been filed against Apple in the US. In 2020, Apple agreed to a settlement under which the company paid up to 500 million US dollars to affected customers.

Printers are another troublesome example. Many printer manufacturers build chips into their cartridges that prevent them from being refilled. Some printers also display error messages or refuse to work when ink levels are low, even if there is still enough ink for further prints.

If brake discs are coated with tungsten carbide using a high-speed flame spraying process, they can remain maintenance-free for the entire service life of the vehicle. At the same time, particulate emissions are massively reduced - Photo: Andreas Bednareck

If brake discs are coated with tungsten carbide using a high-speed flame spraying process, they can remain maintenance-free for the entire service life of the vehicle. At the same time, particulate emissions are massively reduced - Photo: Andreas Bednareck

Everyday scrap

We now encounter the problem of planned obsolescence everywhere. The impression that most products only last from noon to noon is no coincidence. Foodstuffs are often given expiration dates that are shorter than their actual shelf life in order to boost sales. Razor blades are manufactured in such a way that they quickly become blunt. Even expensive hair clippers often contain delicate plastic parts that wear out after a certain number of uses - preferably after the warranty has expired.

This is supported by what is known as perceived obsolescence. Through advertising and marketing, consumers are led to believe that their products are no longer any good, even though they are still functional. This buying behavior is accelerated by "social proof", i.e. the desire to keep up with the latest trends. Consumers are motivated to replace older but still functional products with newer ones. In addition to the electronics industry, the fashion industry is particularly noteworthy here.

Apple founder Steve Jobs with a Macbook. Apple has been accused of slowing down older iPhone models with software updates to encourage customers to buy new devices - Photo: Matthew Yohe, CC BY 3.0, wikimedia

Apple founder Steve Jobs with a Macbook. Apple has been accused of slowing down older iPhone models with software updates to encourage customers to buy new devices - Photo: Matthew Yohe, CC BY 3.0, wikimedia

Surface technology as a role model

No surface coater would think of deliberately applying a poorer coating in order to win new orders. Only the big players in business and industry can afford to do this. The examples shown illustrate the tense contradiction between the technical possibilities of long-lasting production and mass production for a throwaway society that is subject to the constraints of constant growth. Will this contradiction be overcome one day in view of climate change? We shall see.

But back to electroplating technology: 7.5 instead of 8.0 µm, 140 instead of 144 hours in the SS test and other complaints may be factually correct, but they do not make the world a worse place. On the contrary: if all branches of industry planned and worked as conscientiously as surface technology, we could live in a much better world because it would conserve resources. Sustainability through electroplating and surface technology is not just lip service. After all, longevity, which our industry ensures, is the essence of sustainability. After all, products and applications consume less energy and produce fewer emissions during the manufacture and transportation of new products and the recycling of old ones the longer they last. The diverse coating technologies that give products a long life free from corrosion and protected from excessive wear are therefore sustainable and indispensable - now more than ever!