Scientists at Empa have developed a coating for ropes that indicates the deterioration of mechanical properties by changing color. The coating is complex: it consists of a total of three layers.

Researchers from ETH Zurich and Empa developed a coating system back in 2018 as part of a master's thesis, which the Empa team has now been able to apply to fibers.

The first coatings only worked on smooth surfaces, so the method first had to be adapted so that it would also work on curved surfaces. Empa has extensive expertise in coating fibers - the scientists there have already developed electrically conductive fibers in the past. Sputtering has now also been successfully used for the latest coating.

Color change thanks to physics

Three layers are required for the fiber to actually change color when exposed to heat. The researchers apply silver to the fiber itself, in the case of the research work PET (i.e. polyester) and VectranTM, a high-tech fiber. This serves as a reflector - in other words, as a metallic base layer. This is followed by an intermediate layer of titanium nitric oxide, which ensures that the silver remains stable.

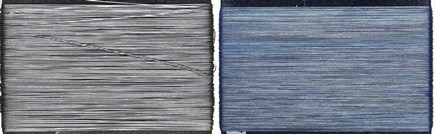

The coated polyester filament before (right) and after the heat test at 150 degrees. The color change from blue to white is clearly visible and the safety of the product is no longer guaranteed (Photo: Empa)

The coated polyester filament before (right) and after the heat test at 150 degrees. The color change from blue to white is clearly visible and the safety of the product is no longer guaranteed (Photo: Empa)

And only then comes the amorphous layer that causes the color change: germanium antimony tellurium (GST), which is just 20 nanometers thick. If this layer is exposed to elevated temperatures, it crystallizes - this changes the color impression, for example from blue to whitish. The color change is based on a physical phenomenon known as interference. Two different waves (e.g. light) meet and amplify or attenuate each other. Depending on the chemical composition of the temperature-sensitive layer, this color change can be adjusted to a temperature range between 100 and 400 degrees and thus adapted to the mechanical properties of the fiber type.

Project partners wanted

The potential areas of application for the color-changing fibers are still open, and the company is currently looking for potential project partners.

In addition to safety equipment for firefighters or mountaineers, the fibers can also be used for load ropes in production facilities, on construction sites, etc. In any case, research on the subject is far from complete. For example, the fibers cannot currently be stored for long periods of time without losing their functionality.

"Unfortunately, the phase-change materials oxidize over the course of a few months," says one scientist. This means that the corresponding phase change - crystallization - no longer takes place even when exposed to heat and the rope therefore loses its warning signal. In any case, the principle has been proven to work and durability is a topic for future research. As soon as the first partners from industry register their interest in their own products, the fibres can be further optimized according to their needs.