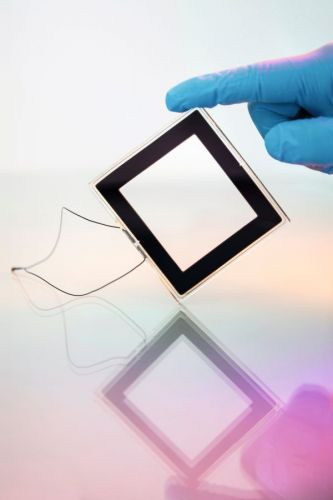

Charging smartwatches, keyboards and the like could soon be a thing of the past. The spin-off "Perovskia Solar" from the Swiss Federal Laboratories for Materials Science and Technology (Empa) prints customized solar cells for almost any electronic device. The solar cells can be produced cost-effectively - and even work indoors.

Every person owns an average of seven electronic devices. There are several billion devices in use worldwide - and with the Internet of Things (IoT), the number is growing. These need to be charged regularly or their batteries replaced. The Empa spin-off "Perovskia Solar" has therefore specialized in custom-made solar cells for every conceivable electronic device.

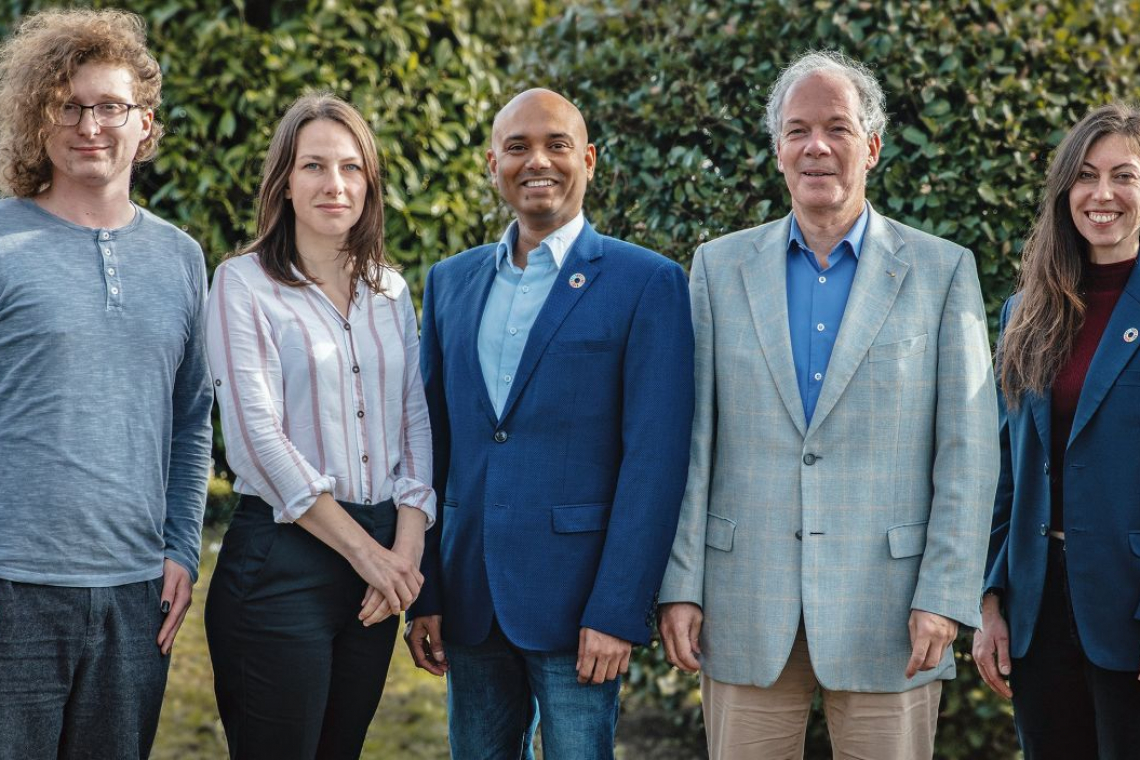

Printed solar cells could soon be used to power our many electronic devices - even indoors. Scientists at Perovskia Solar in the new factory in Aubonne, Switzerland

Scientists at Perovskia Solar in the new factory in Aubonne, Switzerland

Conventional silicon solar cells are complex to customize, expensive and inefficient in low light conditions. "We can print innovative perovskite solar cells in any size - and at low cost. With their high efficiency, they can power almost any electronic device indoors in bright home and office lighting," says company founder Anand Verma.

A new factory for customized solar cells

Perovskites have two outstanding properties: they absorb light particularly efficiently and conduct the generated electricity well. Until now, however, perovskite-based solar cells were not stable enough and not durable enough for large-scale use. Anand Verma therefore spent five years at Empa researching printing processes for perovskite solar cells before setting up his own company in 2020.

The Empa spin-off is currently on the road to success: "Perovskia Solar" supplies over 25 international companies with solar cells for the IoT and consumer electronics devices. The Empa spin-off recently set up a factory in Aubonne in the canton of Vaud. One million perovskite elements are to be printed there every year to equip electronic devices with solar cells that supply our digital lifestyle with electricity.

Vacuum processes such as CVD and PVD (chemical vapor deposition, physical vapor deposition) are used for regular solar cell coating. These processes are also mastered by the Functional Polymers department at Empa. One of the department's three groups is called Functional Thin Film Solution Processing and deals with printing as a manufacturing process. This is where founder Anand Verma laid the foundations for Perovskia Solar with his research.