When the CD finally established itself on the market at the beginning of the 1990s, vinyl recordings were declared dead. In fact, sales of black disks collapsed to less than one percent of the total market within a few years. However, a few upright people held on to analog singles and LPs. One of them is Björn Bieber, who specializes in the electroforming of pressing matrices - and works on orders from all over the world as a one-man company.

Vinyl panels are like vintage cars: they are fragile, impractical, have flaws and are also difficult to produce. But aficionados swear by the warm sound, the subtle crackling in the carpet of sound and the sensual feeling when you peel the shiny black disks out of their sleeves.

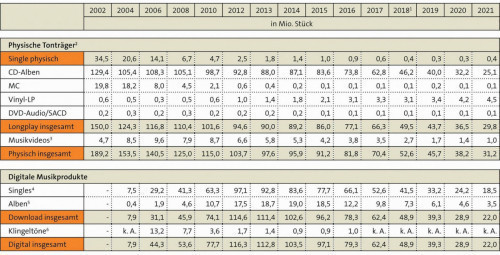

Sales of sound carriers in recent years (Source: German Music Information Center/Music Industry in Figures)

Sales of sound carriers in recent years (Source: German Music Information Center/Music Industry in Figures)

Because of this - or despite it - the analog record was practically dead in the 1990s. In 1994, a total of 166.2 million CDs were sold in Germany, but only 0.7 million records. That was just 0.4 percent of the total market (further figures in the table).

"Records are really impractical," admits Björn Bieber

"Records are really impractical," admits Björn Bieber, who makes his living producing vinyl records. "With a CD, it was not only easier right from the start, you also had a lot more options (in terms of sound)."

At 46 years old, Bieber is actually more at home in the digital age, but since graduating in business administration, he has dedicated himself entirely to analog vinyl. Bieber initially worked at the Freiburg-based label flight 13 records before he had the idea of producing the records that were sold there himself. This is how Bieber got into record production and soon he was not only pressing records for flight 13 records, but also accepting orders from third parties. During the first few years, his new company flight 13 duplication offered all the production steps involved in making a record - except for the electroplating. This was bought in from a French company. Since the beginning of this year, the situation has been reversed. Bieber has given up all production processes before and after the electroplating of a press die and now only does electroforming. "I was close to burnout," he explains his move. "We sometimes pressed plates for 20 hours at a time, then slept for four hours on camp beds next to the machines and then carried on." Today, he runs his business in a more relaxed way. "I can produce up to ten pressing matrices in one day, that's five records, each with an A and B side, of course.

INFO

16 steps to the finished record

Preparatory work in studios

- Recording a piece of music in a recording studio

- Converting the electrical signal into mechanical signals.

This is how the cutting foil is created

In the electroplating shop

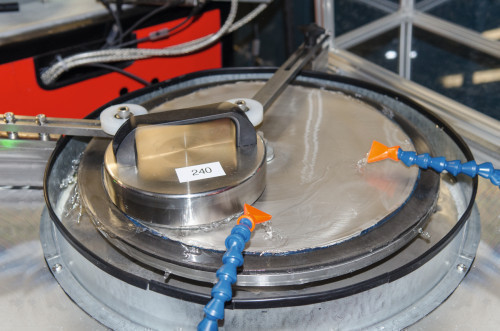

- Pre-treatment of the cut film: degreasing, activating, silver plating

- Pre-electroplating: A fine nickel layer is created on the cut foil

- Main electroplating: The father is created in a nickel sulphonamate bath

- Backup copy: An exact replica of the cut foil, the so-called mother, is immediately produced from the father

- Press matrices: Any number of press matrices, the

the sons can be made from the mother - Post-treatment: Polishing of the reverse side, punching of the center hole

- Forming the edge and center hole

In the pressing plant

- Production of the PVC press cake in an extruder

- Fathers or sons of the A (bottom) and B (top) sides are clamped in the pressing machine (hence the crimping)

- The labels are added

- The sheet is pressed at 200 bar at 180 °C

- The crimping edge is cut off

- The finished panel is left to cool for 24 hours

- Packaging in inlay and cover

Electroforming creates the so-called father from the cutting foil

Every sound carrier production begins with the recording of a piece of music in a studio. There, the sounds produced by a singer or a band are recorded electrically. Today it is digital, in the past it was analog, for example on a tape.

Whether digital or analog - this sound carrier from the studio then goes to the editing studio. Bieber: "This is probably the most crucial step for the subsequent quality of a record." Technically speaking, a cutting machine converts the electrical signals from the original recording into mechanical signals. A fine diamond cutter cuts the sounds into an aluminum plate whose surface is coated with a nitrocellulose lacquer. This creates the actual primal sound record, a unique specimen that could be played on a record player. The specialist speaks of a cutting foil.

A fine diamond cutter cuts the sounds into an aluminum plate

This cutting foil is the intermediate product that finally ends up at flight 13 duplication. Björn Bieber degreases the cutting foil before activating it with zinc II chloride. In a third step, the disk is silver-plated. This means that a machine sprays it from two nozzles with a silver nitrate solution and a reducing solution. Both jets meet in the air and finally together on the pickled cutting foil. This is where the conductive silver layer is formed.

The next step is pre-plating. Bieber applies a fine nickel layer in around 15 minutes at a bath temperature of 35 °C. Finally, a flat nickel plate around 0.2 millimetres thick and weighing around 200 grams is produced in the main electroplating process. This plate is deposited from a nickel sulphonamate bath at a low voltage (11 V) and 150 A. The duration of the deposition process at these energy values is around one hour and 15 minutes. The resulting record is a negative of the cutting film and therefore cannot be played back. Experts call this intermediate product the father.

The father is a non-playable negative of the cutting film

An iron rule in record production is that you should not make any more fathers from a cutting film. A metallic copy of the cutting foil is therefore immediately made from the resulting father. The so-called mother is created. If no mother was made and the father was damaged in the further production process or lost during transportation, the time-consuming production of a cutting foil would have to be started all over again. The nut is therefore archived in the vast majority of cases.

To summarize the process in another way: The cutting film is effectively a playable (primal) version of a record with engraved grooves. The resulting father is a non-playable version, a negative, with bumps instead of grooves. The later print, the mother, is a positive. It is therefore playable again because it has grooves. Any number of negatives, so-called sons, can then be made from this mother.

A maximum of 2000 records can be pressed from one father (or one son)

Making two, three or ... n sons is not necessary for small record productions. However, large runs, which often run on several pressing machines, require a large number of sons. Depending on the quality, a father (or son) can press a maximum of 2000 records before he has to be replaced.

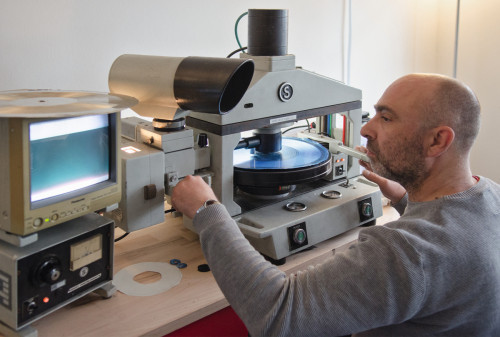

A finished LP measures exactly 30 centimetres in diameter

Björn Bieber's main work is completed after the father is made. However, there are several subsequent steps that should not be neglected. Because these also contribute to the later quality of a record. After the father has been removed from the cutting foil, its reverse side is carefully polished. The next step is to determine the exact center of the record. This is important because if the center hole is punched inaccurately, the vinyl record will be eggy. The center hole is determined using a special machine with a microscope. The run-out groove of the record is helpful here. The center hole of the pressing die is then exactly one inch in size, and the final process is the forming of the record edge and center hole. A finished LP measures exactly 30 centimeters in diameter. After electroplating, however, it is several centimeters larger. Some of the edge is therefore cut off first and the rest is flanged. This is necessary so that the pressing die can later be clamped in the pressing plant.

Father or sons finally arrive at the pressing plant. The employees in the pressing plant have already extruded the press cake from plastic pellets in an extruder. This is the material that gave vinyl its name: a special rigid PVC (where PVC stands for polyvinyl chloride). The analog sheet, colloquially known simply as vinyl, is therefore nothing more than a shortening of the type of plastic PVC to the V in the middle.

It should be added that the record label and the center hole are applied directly during the pressing process. The A-side is at the bottom during pressing, the B-side at the top. Due to the 200 bar pressure and 180 °C processing temperature, the vinyl forms a pinch edge, which is later cut off. After a day's rest, the finished record is finally packaged - first in the inlay and later in the cover.

INFO

History and markets

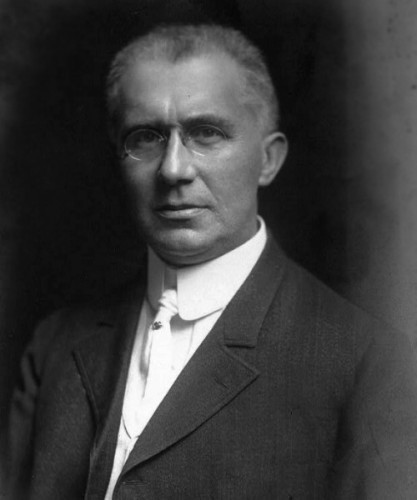

Emil Berliner was the first to produce a record by electroformingFrom1857

Emil Berliner was the first to produce a record by electroformingFrom1857

Precursor of the vinyl record as a roller or wax record

1887

Emil Berliner produces the first modern record by electroforming

From 1888

Experiments are carried out with various materials: records are made from celluloid, later from hard rubber. Mixtures of phenol, formaldehyde, sawdust and clear lacquer were also experimented with. Finally, shellac, a precipitate of the lacquer scale insect, became established.

From 1930

The expensive natural product shellac was replaced by PVC - the vinyl record was born. From this year, the diameter of a record (LP) is also set at 30 cm and the playback speed at 33 1/3 revolutions per minute. The so-called single was not standardized until 1949: Diameter 17.5 cm at 45 rpm playback speed

Today

In the 1970s, the record was joined by the music cassette as a sound carrier, and especially from the mid-1980s by the CD. The appearance of the more practical CD caused the sales figures for analog sound carriers, especially LPs, to plummet. In 2002, almost 130 million CDs were sold, but only 600,000 records. The low point was reached in 2006. Only 300,000 LPs were sold. But that was also the turning point. What no one would have expected happened: the sales figures for vinyl records recovered step by step: as early as 2012, one million analog records were sold again, in 2015 the two million mark was broken, in 2016 it was already 3.1 million records again and today (last available figure 2021) it is even 4.5 million again.

Outlook

Despite this development, the market for physical sound carriers is declining significantly every year. While vinyl records may succeed in regaining market share within this segment, the future belongs to streaming services in the long term. Music sales outside the streaming segment are in sharp decline. While the declining sales figures for physical sound carriers were offset by the digital market until the beginning of the 2010s, sales of digital music products have also declined significantly in recent years. In 2021, sales of 18.5 million digital singles were offset by only around 400,000 physical singles. Longplays, on the other hand, are mainly sold physically: 29.6 million music albums sold on CD, vinyl, cassette and DVD-Audio/SACD compared to 3.5 million digital albums.

(Source: German Music Information Center/Music Industry in Figures)

All photos: Heinz Käsinger