Two-dimensional (2D) semiconductors have proven to be promising candidates due to their unique atomic layer structure and their special surface. The classical Si metal oxide semiconductor field effect transistors (MOSFET) suffer from this disadvantage. 2D semiconductors such as single-layer MoS2 have attracted a lot of attention due to their exceptional electronic and optical properties. However, their practical application has been hindered by limited light absorption due to atomically thin thickness and low quantum yield.

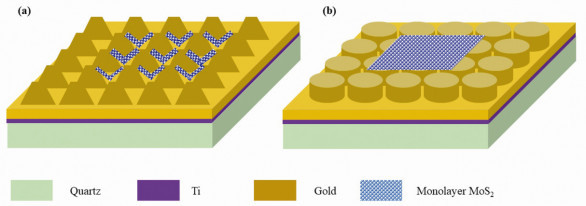

A very effective approach to overcome these limitations is the integration of sub-wavelength plasmonic nanostructures with single-layer semiconductors. Engineers and scientists at the Indian Institute of Technology Bombay (IITB) have developed a plasmonic platform of gold nanodiscs (AuND) using electron beam lithography (EBL) and nanoelectroplate technology. A monolayer of MoS2 deposited on the AuND array leads to up to 150-fold enhancement of photoluminescence compared to a gold film without normalization of plasmonic hot spots. In addition, the unique nanoelectroplating protocol helps to obtain flat-top cylindrical disks that allow less cracking during the delicate wet transfer of a monolayer of MoS2. A polystyrene-assisted wet transfer process was used to transfer a monolayer of MoS2 onto an AuND array. In the physical vapor deposition method, the metal is deposited in the exposed areas and on the resist. In the electroplating method, the metal is deposited only in the exposed areas (Figs. 1 and 2). Fig. 2: AuND array fabricated with (a) EBL and physical vapor deposition and (b) EBL and nano-galvanization technique

Fig. 2: AuND array fabricated with (a) EBL and physical vapor deposition and (b) EBL and nano-galvanization technique

The experimental results were interpreted using electromagnetic simulations. In this work, a novel protocol was developed using EBL followed by nano-galvanization leading to a cylindrical AuND array with a flat top. MoS2 monolayers can be transferred to this modified surface relatively easily and without large cracks. ACS Appl. Mater. Interfaces 2023, 15, 49, 57783-57790; https://doi.org/ 10.1021/acsami.3c11564

Phase change materials and electroless copper plating

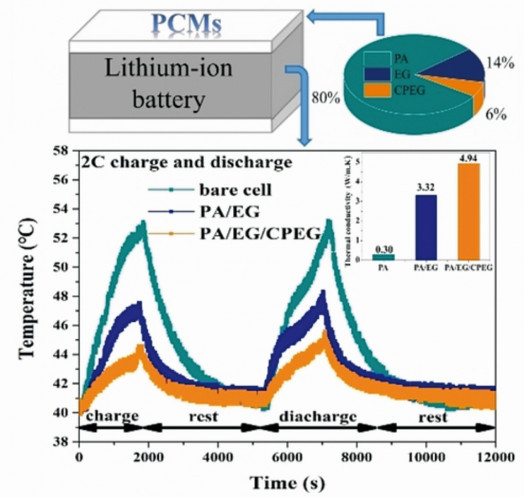

There are three types of thermal energy systems, which are categorized into sensible heat, latent heat, and thermochemical systems. Phase change materials (PCMs) are a possible answer to the global energy problem. They have the ability to store and release thermal energy when they change from one phase to another. In addition, latent heat storage using PCMs is one of the most effective and sought-after thermal energy storage systems due to its ease of use and similar energy storage density. PCMs are frequently and widely used in latent heat energy storage (LTES) and thermal management (TM) systems due to their large latent heat and ability to maintain a near constant temperature. Improved thermally conductive phase change materials are produced by incorporating copper-coated expanded graphite (CPEG) with a porous 3D structure, produced by electroless copper plating, into kerosene wax (PA) and expanded graphite (EG) composites. The PA/EG/CPEG composites show remarkable thermal conductivity and temperature control effect on lithium-ion batteries. PA/EG composite is suitable for phase change with low cost, high heat storage, good thermal conductivity and cycling stability. However, its thermal conductivity needs to be further improved for application in the thermal management system of lithium-ion batteries. In this work, copper-coated expanded graphite (CPEG) with porous 3D structure was prepared by electroless copper plating by scientists from Beijing, which was used as a material to improve thermal conductivity to replace part of EG in PA/EG composite materials (Fig. 3). Fig. 3: Thermal conductivity improvement of PA/EG/CPEG composite material

Fig. 3: Thermal conductivity improvement of PA/EG/CPEG composite material

For the optimized phase change material, which consists of 80% PA, 14% EG and 6% CPEG, the copper content is very low (0.768 wt%), but its thermal conductivity can be significantly improved without loss of latent heat and thermal cycling stability. Compared to the copper-free composite (80 % PA, 20 % EG), its thermal conductivity increases from 11 times to 16.5 times that of kerosene. The PA/EG/CPEG composite material shows good temperature control in lithium-ion batteries. ChemPhysChem 2023, 24, 23; https://doi.org/10.1002/cphc.202300320

Leading conference of the Indian electroplating industry

The Metal Finishers' Association of India is the leading organization for the electroplating industry in India. It is once again organizing a three-day exhibition and conference in Greater Noida outside New Delhi from 14 to 16 February 2024. The event, under the auspices of the International Union of Surface Finishing IUSF, will be held in Hall 15 of the India Exposition Mart. It is the first ISF show after 2017. The last industry show in India was organized in New Delhi. https://isfmfai. com/wp-content/uploads/2023/07/Brochure-ISF-copy.pdf