In Germany, fire incidents occur frequently in surface treatment companies, especially electroplating, anodizing and printed circuit board companies. Preventive fire protection and early fire detection play a key role in avoiding major fire damage and environmental pollution. The topic is also of great importance with regard to risk protection, as insurance companies have now started to set very high fire protection requirements, demand unusually high premiums or no longer insure companies in the surface technology sector at all.

For surface technology companies in Germany, this is often a matter of survival. A study conducted by the French Ministry of the Environment in June 2022 confirms that this trend has also been observed in France in recent years, with a strong upward trend [1]. The top priority in fire protection should be to prevent fires from starting in the first place. If it cannot be avoided, the first few minutes after the fire starts will determine how it progresses. If a fire breaks out, damage to the aquatic environment and possible environmental and legal consequences can be averted by adequately dimensioned and maintained extinguishing water retention in advance.

Frequency and cause of fire incidents in the surface industry

"A rough rule of thumb is that a major fire occurs in an electroplating plant in Germany approximately every three months, i.e. around four major fires per year. A major fire is defined as an incident with a loss of more than one million euros. The much more frequent smaller fires are not counted here [2]."

A rough rule of thumb is that a major fire occurs in an electroplating plant in Germany approximately every three months

The German Central Association for Surface Technology (ZVO) writes in its 2021 annual report: "In recent years, countless major fires have alarmed the operators of electroplating and other surface technology companies and at the same time focused the attention of insurers on electroplating and surface technology. Fire and explosion damage usually merge seamlessly with environmental damage and generally lead to long-term business interruptions. Placing customer orders with competitor companies, loss of market share, customers, image or employees are just some of the major challenges that the company has to overcome after a major fire damage in parallel to the claims settlement and reconstruction [3]."

![Abb. 1: Anzahl der gemeldeten Umweltfälle in der Oberflächenbranche in Frankreich; oberste, orangebraune Linie: Brandfälle [1] Abb. 1: Anzahl der gemeldeten Umweltfälle in der Oberflächenbranche in Frankreich; oberste, orangebraune Linie: Brandfälle [1]](/images/stories/Abo-2024-02/thumbnails/thumb_gt-2024-02-080.jpg) Fig. 1: Number of reported environmental incidents in the surface industry in France; top orange-brown line: fire incidents [1]

Fig. 1: Number of reported environmental incidents in the surface industry in France; top orange-brown line: fire incidents [1]

It is estimated that only about 1/3 of companies survive a fire incident for a long time [4]. In France, the number of reported cases has risen continuously and recently by leaps and bounds, as Figure 1 shows.

Causes of fire

The main cause of fires in surface treatment plants is electrical current. "The combination of heat sources, corrosive loads and the transmission of electrical energy represents a high potential for fires in electroplating plants [4]." The possible ignition sources are supplemented in rarer cases by flammable work (e.g. welding), hydrogen explosions, arson and chemical ignition sources.

The combination of heat sources, corrosive loads and the transfer of electrical energy represents a high potential for fires to occur in electroplating systems

An example of accidental arson is a smoldering cigarette that was carelessly thrown into a waste water shaft (illustration - cover picture). The cigarette ended up in a pump sump for rainwater and - possibly leaking - acids and alkalis. Solvents were not involved. Particularly in the summer months, or in persistently dry periods, dust, leaves, fine branches etc. can accumulate in these sumps, which in this case, in combination with the smouldering cigarette, led to a very clear and rapid fire development. It has been shown that it is very important to clean these shafts regularly. This also applies in the event that acids or alkalis get into the shaft intended for this purpose. A reaction with the organic components is to be expected.

A chemical ignition source that should not be underestimated is sodium dithionite, which is often used for chromium (VI) reduction in wastewater treatment. It self-ignites even with small amounts of water (e.g. when using a damp dosing scoop) and continues to burn on its own, like lithium ion batteries. Dried aerosols of oxidizing process solutions (e.g. ammonium nitrate, potassium nitrate) in ventilation systems can also ignite or contribute to a very rapid spread of fire. Prof. Dr. W. Hasenpfusch describes other possible ignition sources in a series of articles in Galvanotechnik [5].

Fire protection - fire prevention

Recommended preventive measures and safety equipment:

- no use of electric bath heaters (frequent source of ignition - safer alternative: indirect bath heating using hot water or steam)

- if electric bath heaters are unavoidable, then only safety bath heaters with redundant safety monitoring against overheating should be used

- Regularly check all electrical contact points (e.g. 12x/a) such as product carrier contacts, contact anode rails and baskets

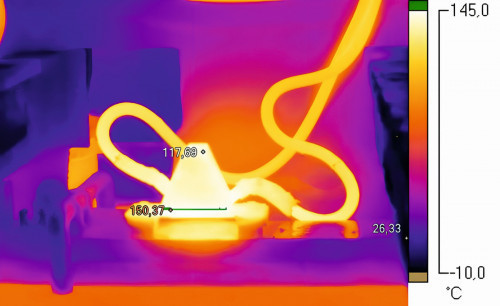

- Contacts of the anode baskets on rails with suspended baskets are easily heated if the contact is inadequate. This can lead to arcing and thus to the ignition of surrounding plastic components. The extraction system also intensively draws in fresh air, which significantly accelerates a fire. This problem occurs partially, especially with older baskets and rails, and temperatures of over 100 °C (measured using a thermal imaging camera) are quickly reached even with a minimal contact point. The contact surface of anode baskets and busbars should be checked regularly (Fig. 2a and b).

- For anode baskets that are attached to the anode rail using screws, it is recommended that the contact screws are tightened using a torque wrench (e.g. to 25 Nm) not just twice a year, but 12 times a year.

- All-pole current disconnection during shutdown (ZVO recommendation)

- sufficiently large cross-sections for current-carrying cables / rails - current feeds on both sides of electroplating baths have proven to be advantageous here

- Sufficient extraction to avoid hydrogen explosions (some pickling processes, electrolytic degreasing, chrome baths) - note possible hydrogen accumulation in the event of extraction failure and sudden resumption of power supply

- In barrel electroplating systems, the "finger contacts" must generally be checked for cleanliness, corrosion and function during maintenance in the electroplating system in order to ensure the necessary contact surface for current transmission. As barrel electroplating systems can sometimes be subject to heavy spattering when the barrels are moved out, it is recommended that the condition of the contacts is also checked during production and, if necessary, combined with suitable early detection methods (visually or better with a thermal imaging camera)

- Staff training combined with checklists for inspection are suitable as proof.

Fig. 2: a) Contact block and cable in the visible range; b) Contact block and cable in the infrared range (approx. 150.37 °C)

Fig. 2: a) Contact block and cable in the visible range; b) Contact block and cable in the infrared range (approx. 150.37 °C)

Early fire detection

- Use of modern automatic fire detection systems, e.g. aspirating smoke detectors (RAS system), which are designed for the special conditions in an electroplating plant and can distinguish fire smoke from other typical operational contaminants

- Install fire detectors in switch cabinets - including effectiveness testing at regular intervals

- Regular or even permanent inspection of the systems for unusual heat development using thermography / thermal imaging cameras. Very good mobile systems are now available on the market, as well as fixed systems with 24/7 operation, which are suitable for monitoring.

- Instead of the sprinkler systems often required by insurance companies, other measures such as the installation of thermal imaging cameras and/or the installation of PT100 temperature sensors on live rails/contacts can be taken if necessary.

Recommendations of the Central Association for Surface Technology (ZVO):

- Annual inspection of all electrical systems by an expert recognized by the VdS (Verband der Schadenversicherer e.V.) including thermography

- ½-yearly inspection of portable equipment

- ¼-yearly inspection of safety equipment.

Positive practical example

A company in the surface treatment industry, which complied with the above-mentioned ZVO recommendations, nevertheless suffered two electroplating fires in one year. As a consequence of the first fire, thermal imaging cameras with 24/7 monitoring and connection to the fire alarm control panel (FACP) were installed. This monitoring was accepted by the property insurer as an alternative to a complete sprinkler system, which was also considerably more cost-effective and proved its worth. In the second fire, despite unfavorable circumstances, the thermal imaging monitoring system was triggered 3 minutes before the aspirating smoke detection system (RAS system), enabling employees to extinguish the fire at an early stage. This meant that the fire department was only required to extract smoke from the production hall.

Organizational measures

- Risk assessment; instruction of internal and external employees - for regular operation and disrupted operation - also during repairs: welding, cutting, soldering, cutting, ...

- Explosion protection document

- Fire inspections and fire drills (every 5 years)

- Sufficient extinguishing water supply

- Sufficient retention of extinguishing water.

Maintenance and servicing

- Regular cleaning of all system parts - including the exhaust air ducts - according to a cleaning and maintenance plan monitored by the management (usually twice a year)

- Regular electrical system inspection (VDE 0105-100) by a qualified electrician - insulation faults with currents of 100 mA can cause fires!

- Regular inspection of electrical system components using thermographic inspections (thermal imaging camera).

Extinguishing water retention

Extinguishing water from surface technology operations is generally contaminated or highly contaminated, i.e. de facto "hazardous to water". It can also be contaminated with PFAS if AFFF extinguishing foams are used. The UNECE guideline: "Safety guidelines and good practices for the management and retention of firefighting water [6]" therefore concludes: "Because firefighting water must always be considered contaminated, special considerations must be taken into account when disposing of it".

"Because firefighting water must always be considered contaminated, special considerations must be taken into account when disposing of it"

This sentence was impressively confirmed by an incident in Berlin in 2019. In an electroplating fire with damage amounting to well over 100 million euros, the extinguishing water caused the total failure of the city's sewage treatment plant with subsequent fish mortality. The tragedy in this case was that the company was already in the process of installing sufficiently dimensioned extinguishing water barriers in accordance with VdS 2557. However, the fire occurred before the work was completed and the extinguishing water still escaped.

In the event of inadequate retention, extinguishing water can enter bodies of water directly via floor drains or via the sewage system into municipal sewage treatment plants and damage or kill them. Extinguishing water can also flow directly into bodies of water via rainwater overflow basins in the case of indirect dischargers or seep into the groundwater via house drainage systems and thus endanger the drinking water supply.

Technical protective equipment

- Sufficiently dimensioned extinguishing water retention and disposal

- Recommendation: fixed, preferably central extinguishing water retention areas (e.g. install the entire electroplating and/or waste water treatment plant in a tank)

- Design internal water downpipes with fire resistance class F 90 up to the maximum expected water retention height in the event of extinguishing water (Fig. 3 and 4)

- Avoid flammable plastic waste water pipes that penetrate the extinguishing water tray and melt away in the event of fire

- Extinguishing water retention barriers - extinguishing water bulkheads (Fig. 5)

- For existing systems, provide mobile sealing materials, manually deployable extinguishing water bulkheads, sewer seals, sewer bladders on site if necessary [1].

Dimensioning the extinguishing water retention volume

VdS 2557 "Planning and installation of extinguishing water retention systems [7]" has proven to be the best and most realistic calculation model for companies in the surface treatment industry. This source of knowledge, which is provided free of charge and also in English by the German Property Insurers' Association including a calculation tool, covers all factors relevant to the surface treatment industry. On the one hand, it takes into account that in the event of a major fire, experience has shown that both the quantity and the hazardousness of the extinguishing water is significantly increased by the leakage of all liquid chemicals, baths, etc. On the other hand, the firefighting measures taken by the company are taken into account. On the other hand, fire protection measures taken by the company are "rewarded" in the calculation and lead to a lower extinguishing water retention volume.

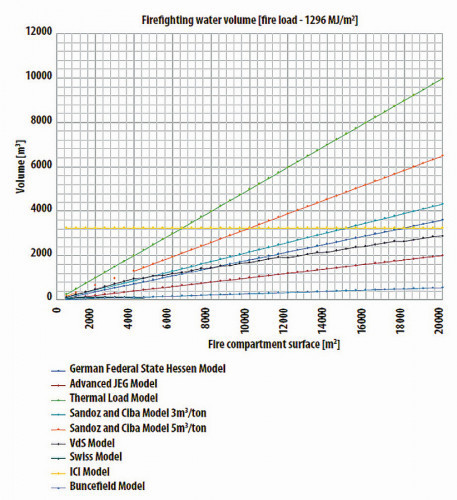

As the graph in Figure 6 shows, VdS 2557 is balanced in the middle range in an international comparison when calculating firefighting water retention volumes and therefore does not set any excessive requirements.

Summary:

In order to prevent the occurrence of a major fire or to limit the effects in the event of damage, it is important to check the points and recommendations listed above for your own surface treatment plant and to derive and implement the appropriate measures. As it is a matter of averting an existential risk, it is also recommended to implement measures that go beyond any specifications required by the authorities.

A step-by-step approach to improving fire protection measures on a technical level and organizational measures is recommended. The retention of extinguishing water must also be planned and implemented. Particular attention should be paid to the necessary maintenance, relatively short maintenance periods and the care required during the process. Another important aspect is the safety culture and the awareness of the personnel in the surface treatment plants, both when operating the plants and when dealing with critical situations. Regular training and safety inspections are the means of choice here.

Literature

[1] Ministère de la Transition Ecologique 06-2022: "Accidents involving fires at surface treatment facilities"; https://www.aria.developpement-durable.gouv.fr/wp-content/uploads/2022/11/2022_10_13_Synthese_TS_MG_VFinale_EN.pdf

[2] Galvanotechnik 7/2019: W.Willand "Fires and extinguishing water retention in electroplating plants"

[3] ZVO Annual Report 2021 p.82, https://www.zvo.org/fileadmin/zvo/ZVOJahresbericht/2022/ZVO_Geschaeftsbericht_2021.pdf

[4] Womag, issue 2/2022: Frank Schüle

[5] Galvanotechnik 1-3/2019): W.Hasenpfusch, series of articles: "Explosion protection in surface technology"

[6] UNECE 2019: "Safety guidelines and good practices for the management and retention of firefighting water"; https://unece.org/sites/default/files/2020-12/ece_mp.wat_58_ENG.pdf

[7] VdS 2557: Planning and installation of firefighting water retention systems Extinguishing water volume calculation sheet - free download: http://vds.de/fileadmin/vds_publikationen/vds_2557a_web.pdf" target="_blank">http://vds.de/fileadmin/vds_publikationen/vds_2557a_web.pdf

Further sources of information:

- VdS 3412 2018-01: "Electroplating plants - hazards, risks, protective measures"

- VdS 2557: Planning and installation of extinguishing water retention systems, extinguishing water volume calculation sheet - free download:http://vds.de/fileadmin/vds_publikationen/vds_2557a_web.pdf" target="_blank">http://vds.de/fileadmin/vds_publikationen/vds_2557a_web.pdf

- Water protection during fires in industrial and commercial enterprises - responsibilities and extinguishing water management. Exchange of experience in Baden-Württemberg. https://www.lfs-bw.de/Fachthemen/abceinsatz/.../Gewaesserschutz_bei_Braenden.pdf Literature

All photos: W. Willand