Energy saving series part 7 What else can be done to save electricity and energy in a modern electroplating company? The latest generation of compressors have been installed at MVB in Bretten and Strähle Galvanik GmbH in Zaisenhausen. These work with frequency-converted motors and can therefore save a reasonable amount of electricity.

How they work

The main component of a compressor is its motor, which drives the compressor. In common parlance, the compressor itself is often referred to as the compressor, although this is only one part of the compressor. The air compressed by the compressor is not directly expelled again. A pressure vessel, into which the compressed gas is pumped, distinguishes the compressor significantly from the air pump and motor and offers various advantages. For example, the pressure tank can store larger quantities of air than the piston of the compressor can continuously deliver. This air can then be expelled as a total quantity. This also means that the compressor motor does not have to be in continuous operation. Important parameters are therefore

Intake capacity

The intake capacity is the amount of air that the device draws in order to compress it and convert it into compressed air. The value is given in liters per minute (l/min). The intake capacity of a piston compressor is always greater than the output capacity, which is significantly more important. Therefore, the intake capacity is not ideal as a performance indicator and is only of limited significance. However, the situation is different with a screw compressor. Here, no distinction is made between intake and output performance, as the compressed air losses (also known as blow-by) are much lower than in a piston compressor. The pressure loss in a screw compressor is generally less than 0.2 %. However, due to the price, very few compressed air generators for private use are screw compressors.

Output capacity

The output capacity of a compressor, also known as the delivery rate, indicates the amount of compressed air that the compressor can provide. This compressor parameter is the most important comparative value. The output capacity is determined on the basis of a standard. Depending on the cut-out pressure of the respective compressor, the delivery rate is measured at a back pressure of between 6 and 8 bar (g). In practice, the actual output capacity of a compressor may therefore differ from the specified value, as the value depends on the set pressure.

Filling volume

The filling volume refers to the amount of air that is pumped into the compressed air tank by the compressor (if a tank is available). This is compressed air. The volume can vary greatly as it depends on the back pressure applied. Care should therefore be taken when using this comparative value for compressors. In particular, if the manufacturer only specifies the filling capacity at 0 bar back pressure, you should check the offer again carefully. The filling volume is declared in liters per minute (l/min).

Boiler size

The tank size indicates the volume of the pressure tank. Depending on the requirements and use, the tank volume can be an important compressor comparison value. This compressor characteristic value indicates how high the filling volume of the compressed air tank is. The larger the tank size, the greater the reserve of compressed air and therefore the less strain on the compressor, as it does not have to start up as often. The motor only starts again when the pressure in the tank falls below a minimum level. The tank size is specified in liters.

Capacity

The power of a compressor describes the strength of the electric motor that drives the piston. The power is specified in watts or horsepower. As a compressor indicator, the electrical power is only of secondary importance, as the output power - i.e. the actual air output - is much more decisive here.

Maximum pressure

The maximum pressure of a compressor represents the highest achievable degree of compression of the air that can be realized with the respective compressed air generator. Contrary to expectations, in many cases this compressor comparison parameter is not very important. This is because an exceptionally high air pressure is only required for very few jobs. In most cases, an average pressure is sufficient, which means that this compressor comparison value should only be decisive for a purchase decision in individual cases. The pressure is also measured in bar.

The biggest disadvantages of compressed air

- The production of compressed air is relatively expensive (depending on performance)

- The purchase of a well-functioning system is expensive

- Maintenance after approx. 3000 operating hours is expensive (depending on the oil used)

- Noise level, depending on the application and location.

This makes it all the more important to have a comprehensive concept with state-of-the-art and energy-saving technology.

Which compressors are available?

- Oil-free compressors

- Oil-lubricated compressors

- Piston compressor

- Screw compressor

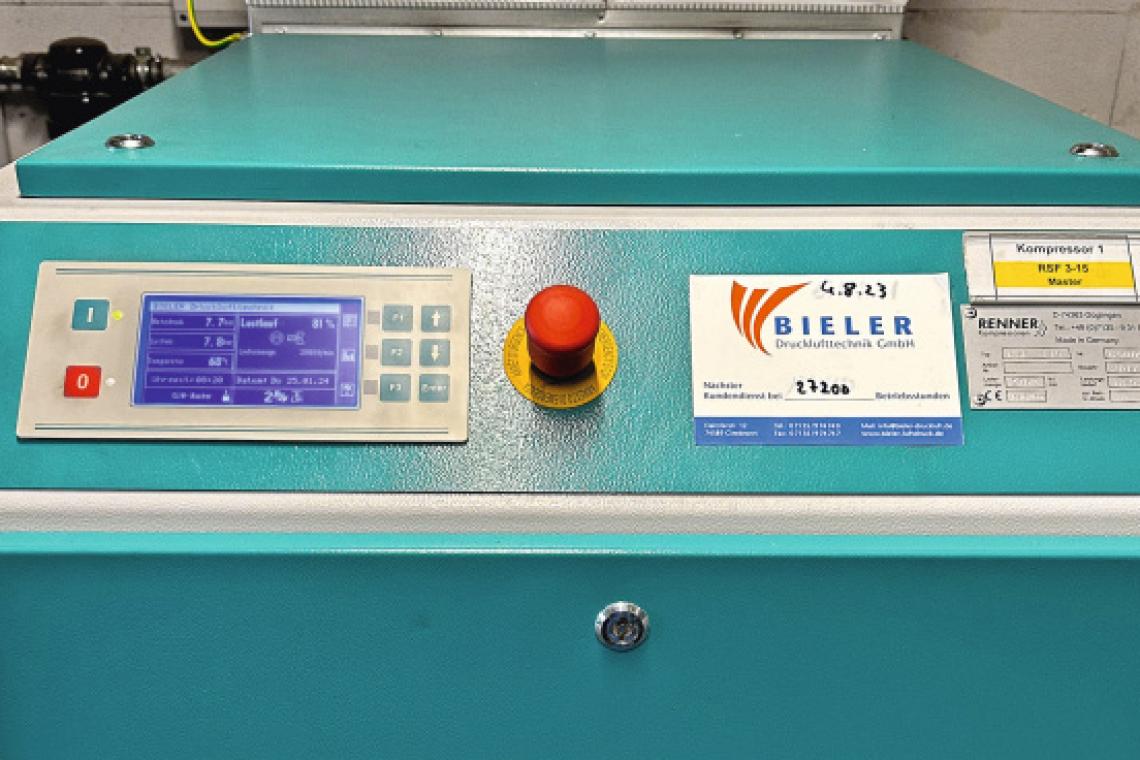

We have opted for an oil-lubricated screw compressor with a frequency-controlled motor. (Figure 1). In order to increase the operating hours, we used a synthetic oil, which means that we achieve 3000 operating hours instead of 2500. If less air is required, the control system regulates the motor down, so we need a relatively small pressure vessel. Fig. 2: Heat recovery for the compressor room and the hall

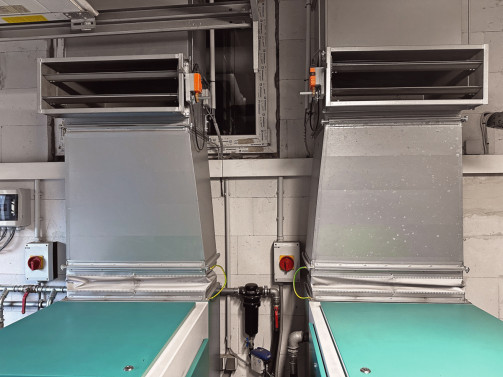

Fig. 2: Heat recovery for the compressor room and the hall

The exhaust air from the compressors is throttled so that in winter the compressed air room is first heated with warm air and then the flaps in the hall are opened (Figure 2). Another proven advantage is the redundant use of a second compressor of equal value. An additional system is also used for the air dryers. We have implemented this for all performance and safety-relevant systems.

As a highlight, we have networked all systems in operation with the air control system so that the main compressed air valve is closed at the end of the working day. This protects the compressors and, should there be a leak, there is no loss of compressed air at the weekend.

In the next issue: Electromobility charging infrastructure