It is estimated that lightning strikes cause around 100 million euros worth of damage to wind turbines every year. The protection systems include an external lightning protection system and a surge protection system, but these have proven to be inadequate. The increasing frequency of lightning strikes - presumably also due to climate change - makes it imperative for the wind turbine industry to manufacture more resistant products that can withstand the harsher operating conditions. Lightning strikes account for 80 % of insurance claims for wind turbines (Fig. 1).

Mankiewicz, a global company based in Hamburg, Germany, which is almost 130 years old and known for its high-quality industrial coatings, has now launched a new coating on the market that is designed to eliminate this problem. The ArcGuide coating uses a polyurethane-based top coat with a special mixture of different elements. It is applied to the turbine blades near the lightning receptors. The ArcGuide coating creates ionized channels on the surface of the turbine blades prior to the lightning strike, which helps the lightning find a safe path to the ground receptors instead of striking through the blade. Lightning strikes are a recurring phenomenon and turbines may be struck several times during their lifetime. Therefore, the coating is designed to continue to function even after a strike to the turbine blade. Arctura distributes the new coating system in the USA.

www.mank iewicz.com/de

Sm-Co composite nanowires

The nanomagnetic material Sm-Co has attracted a lot of attention recently as it is seen as the next generation of permanent magnets with potential applications in energy technology. A considerable number of Sm-Co nanowires have been synthesized in anodic aluminum oxide (AAO) by electroplating in aqueous solutions.

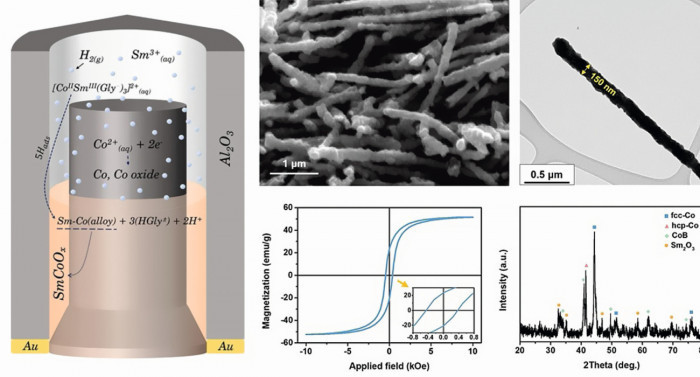

At Sungkyunkwan University in South Korea, electroplating of Sm-Co nanowires was performed using linear voltammetry to ensure a uniform Sm-Co composition ratio. A considerable number of Sm-Co nanowires were synthesized in anodic aluminum oxide (AAO) by electroplating in aqueous solutions. It was found that the addition of boric acid during electroplating suppressed the conversion of the Sm-Co nanowires to the Sm2Co17 phase. The use of boric acid as an additive in the synthesis of nanowires by electrodeposition using an AAO template has been shown to be beneficial for highly ordered morphology; however, this may lead to undesirable problems in the reduction and diffusion process and should therefore be carefully considered. Boric acid prevented the conversion to the Sm2Co17 phase during the R-D process. Boric acid acts as a buffer by forming polyborate and as a suppressor by adsorption on the cathode electrode, which supports the growth of Sm-Co alloy in the AAO pores (Fig. 2).

Dispersed Sm-Co nanowires were synthesized by a combination of annealing for densification and etching of the template. Subsequently, a low-temperature reduction and diffusion process at 700 °C using NaCl, KCl and Ca granules was performed in a facile manner. However, although the one-dimensional structural morphology was maintained, the hysteresis loop in the vibrating sample magnetometer (VSM) did not show the excellent magnetic properties of the Sm2Co17 hard ferromagnet, contrary to expectations. Fig. 2: Parameters and properties of the electrolytic Sm-Co nanowires

Fig. 2: Parameters and properties of the electrolytic Sm-Co nanowires

Appl. Surface Science, Volume 635,

30 October 2023, 157710; https://doi.org/10.1016/j.apsusc.2023.157710

Nickel plating and spot welds

Martensitic stainless steels (MSS) are difficult to weld due to their brittle microstructure both in the weld seam (WN) and in the heat-affected zone, resulting in premature fracture under insufficient load. Engineers from two universities in Tehran, Iran, have investigated whether nickel plating could be an industrial method to improve the spot weldability of MSS. The equilibrium and non-equilibrium solidification models showed that a 50 μm thick Ni coating on 1.5 mm thick MSS changes the solidification mode from δ-ferrite to γ-austenite, resulting in a weld nugget (WN) dominated by austenite grains. Electron backscatter diffraction (EBSD) and electron probe microanalysis (EPMA) showed that the other phases (martensite, δ-ferrite) appeared in the band regions of the WN due to the incomplete mixing of MSS and the Ni coating.

Strategies such as increasing the size of the weld nuggets, tempering the weld nuggets in situ and using Ni interlayers were tested.

The desired surface was then activated in a Woods bath (with nickel chloride and hydrochloric acid) at room temperature and a current density of 16.2 A/dm-2 for a period of 2 minutes, with the anode consisting of pure nickel. In the final stage of the electroplating process, the desired coating was deposited on the prepared surface in a Watts bath containing nickel sulphate, nickel chloride, boric acid and sodium dodecyl sulphate.

The tough microstructure in the Ni-coated MSS spot welds provided better mechanical properties compared to uncoated welds in both transverse tensile (CT) and tensile shear (TS) tests. In particular, the TS and CT strengths of the Ni-coated MSS spot welds showed a remarkable increase of 57% and 127% respectively compared to the conventional bare MSS spot welds. The Ni-coated MSS spot welds showed a significant increase in failure energy of 296% for TS and 520% for CT compared to their uncoated counterparts.

Scientific Reports 2024, Vol. 14, Article number: 3490 (2024)