In court 1

Whatever happens in the world - war, famine, earthquake.... Lawyers are always busy. The last few months have been no exception. Over a year and a half ago, the Nordstream pipelines between Russia and Germany were damaged. Swedish divers found traces of explosives, so there is no doubt that they were sabotaged. But by whom? Russia, Ukraine, the US and the UK have been blamed, but nothing has been proven. Although the German economy has suffered, Russia has lost billions of euros due to the loss of gas exports. Now an energy company, Nord Stream AG, based in Zug, Switzerland, is suing Lloyds of London and Arch Insurance for 400 million euros. The cost of repairing the two pipelines is estimated at between 1.2 and 1.35 billion euros.

The Swiss company claims that the sabotage of Nordstream 1 and 2 should be treated as two separate incidents, which would increase the value of their claim. A date for the trial has not yet been set. Many insurance policies exclude so-called. "Acts of war" are excluded. Was this an act of war? German industry and the government have done an outstanding job in quickly establishing a new natural gas supply chain from the Middle East. The price for this is unknown, and the natural gas has to be liquefied before being loaded onto tankers and then transported to Germany. So do the two pipelines have a future? As long as Russia attacks Ukraine, probably not. And now that a supply chain from the Middle East has been established that seems to be working well, many will argue that it should continue. To come back to the Nordstream pipelines: Who would pay the huge cost of repairing them? Their future is uncertain - but the lawyers will be busy for many months to come.

In Court 2

AI can do wonderful things - and is getting better every week. But - as with any new technology that goes back to steam engines - there are winners and losers. Last summer, thousands of workers in Hollywood went on strike. Some of them wanted a pay rise. But they were also protesting against the increasing use of AI in the film industry. AI can now replace human actors, leading to job losses. Allow me to summarize the situation. AI usually starts with the creation of so-called LLMs - Large Language Models. Not millions, but hundreds of millions, perhaps even billions of pages from newspapers, magazines and books are scanned into a database. This in itself is a very expensive process. However, simply scanning and storing such data does not appear to be illegal under current laws. With the help of AI, this huge amount of data, including images and sounds, human voices and music, can be used to create entirely new content which - because it is new - does not infringe copyright. But without the original input - e.g. from the Frankfurter Allgemeine - this process would not be possible. As a result, dozens of lawsuits are now looming in which the creators of original content are suing the AI companies. A few weeks ago, 50 letters were sent to companies such as Google Deep Mind, Meta (owner of Facebook) and OpenAI (owner of ChatGPT). In the US, the Authors Guild has filed a lawsuit, while Getty Images is suing Stability AI because the company created images using Getty's image database. Universal Music is suing Anthropic and the New York Times is suing OpenAI. In the UK, the music industry is suing Vocify (trading as "Jammable"), which uses AI to create fake performances of famous living and dead singers. These are just some of the proceedings that have already been initiated or will soon be initiated.

We are therefore dealing with a situation in which, according to the applicable laws, nothing illegal is happening and no copyrights are being infringed. Nevertheless, from a moral point of view, money is being made from material created by others. I'm not a lawyer, but I believe that judges have to interpret the law as it is - and that seems to favor the AI companies. Only governments, in my opinion, have the power to change the law. One can only hope that they will do so. In the meantime, lawyers are among the biggest users of AI, and there will probably be job losses there. The same goes for accountants. KPMG, one of the largest accounting firms in the world, has predicted significant job losses as AI is introduced. One of the world's largest publishers, Reed Elsevier, now known as Relx, with 33,000 employees, now offers a range of AI products under its "LexisNexis" banner. I don't think AI will have a big impact on our industry - it's being used to predict failures in pumps and other machinery, but - who knows - maybe I'm wrong.

A new path to green steel?

Conventional steelmaking in blast furnaces is a major source of greenhouse gases and there are many efforts worldwide to replace this old technology. German scientists deserve praise for working to solve two problems at the same time. Aluminum production produces a waste product called "red mud" (Fig. 1). This is produced during the Bayer process, in which bauxite is treated with alkali to form sodium aluminate. Red mud is the residue that results from this process, and there are currently around 4.5 billion tons of it, growing by around 180 million tons every year.

So far, no use has been found for it. In 2010, a huge basin in Hungary where this waste product was stored collapsed, killing ten people and costing around 120 million euros to rebuild. Now scientists at the Max Planck Institute for Iron Research in Düsseldorf believe that red mud could be a new source for iron production. Professor Raabe and his team used plasma chemistry to extract iron from the red mud. The red mud was placed in an electric arc furnace into which a mixture of hydrogen and argon was blown. The sample was then melted with a 200 A discharge and the hydrogen ionized. The iron obtained in this way was purer than that from a blast furnace and around 98% of the iron contained in the red mud was extracted. There are now plans to use the new process on a large scale.

M Jovicevic-Klug et al. Nature (2024) Vol. 625, p. 703.DOI 10.1038/s41586-023-06901-z

Electromobility

It's fascinating to watch technology progress, both as a technologist and as a consumer, and nowhere is this more true than in the development of electric vehicles. A few weeks ago, Toyota announced a breakthrough - a new material to be used in a solid-state battery to achieve a range of around 1500 km and a charging time of just 10 minutes. This new technology is promised for 2027. There seems to be a slight contradiction, as elsewhere Toyota promises a range of only 1200 km. By comparison, the Tesla Model Y has a range of 530 km and a charging time of 15 minutes with the Tesla Supercharger. Honda announced a new polymer fabric to form the basis of its solid-state battery for 2022, but little further information has been released. Until the new battery comes to market, Toyota will offer a new, low-cost bipolar lithium iron phosphate battery. With these batteries, Toyota promises a 20% increase in range while reducing costs by 40% and a charging time of less than 30 minutes. The entire Toyota battery program is too complicated to outline here, but the following link will give you all the details.

https:// media.toyota.co.uk/toyota-sets-out-advanced-battery-technology-roadmap

And of course, many other battery manufacturers around the world have similar technology plans. Two thoughts come to mind. First, would a range of 1200 km be safe enough? We humans get tired long before we have traveled 1000 km. But what if the car is self-driving? Secondly: the shorter charging times. What is very rarely said, but should be clear to all GT readers, is that they mean ever higher currents. This means heavier charging cables and ever greater ohmic losses. The battery of an electric car may have a capacity of around 70 kWh. If we charge it with 200 amps and 200 volts, that's 40 KW - so 90 minutes for a 60 kWh charge. Readers can use their own current-voltage values, but one thing is clear: that very high current-voltage values are needed for a 10-15 minute charge. Are we prepared to pay for these ohmic losses?

Advances in nuclear energy

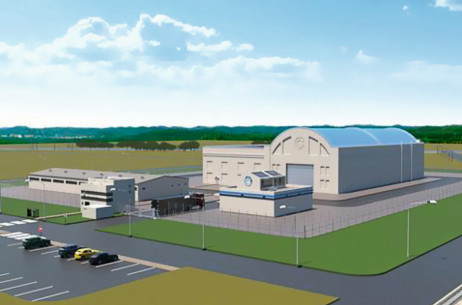

There are dozens of exciting new projects for nuclear power plants, some still in the lab, others already in pilot plants. In the USA, Kairos Power, based in California, has now received approval to build a prototype nuclear power plant. It will be the first in the world to use a coolant made from molten salt. The so-called "Hermes" technology uses a mixture of lithium and beryllium fluorides. This mixture, called "Flibe" (fluorine-lithium-beryllium), remains a stable liquid at 600 °C and therefore offers many advantages over pressurized water, which is used in many existing reactors and operates at around 300 °C and a pressure of 1.5 MPa. Construction will begin next year at a site in the US state of Tennessee. Operating at higher temperatures makes each plant more efficient. Flibe's molten salts do not react violently with air or water, do not decompose when exposed to radiation and have a higher specific heat than water. Hermes technology uses a so-called "pebble reactor". In these pebbles, the uranium fuel is encapsulated in a graphite-coated SiC structure the size of a tennis ball. The plant is scheduled for completion in 2026. Figure 2 shows what the plant will look like. Fig. 2: Diagram of the Kairos nuclear power reactor plant with molten salt

Fig. 2: Diagram of the Kairos nuclear power reactor plant with molten salt

The march of the robots

The US giant Nvidia is known as a leading manufacturer of chips, not least those used in AI applications. The company is increasingly involved in the development of robots. Many of them - like us - have two legs and arms and even a head. Nvidia's goal is to develop robots that simply and easily replace humans, for example in a warehouse - and that are powered by AI. The name for such robots is "Humanoid". Nvidia has developed a new robot operating system. There are dozens of robotics companies today, most of them in the San Francisco Bay Area. Silicon Valley Robotics(www.svrobo.org ) is the umbrella organization. The website provides links to numerous reports describing the latest developments. In the USA alone, there are now 600,000 vacancies for warehouse workers, and companies such as Agility Robotics(www.agilityrobotics.com) are addressing this. Their bipedal (two-legged) robot is called "Digit". Another leading company is www.figure.ai. Both companies (and many others) have videos on their websites showing their robots in action. Experts believe that these robots could be in widespread use in just 2-3 years. Figure 3 is a screenshot from a video on the Agility Robotics website. Fig. 3: A humanoid robot at work

Fig. 3: A humanoid robot at work

Conclusion: With AI on the one hand and robotics on the other, we seem to be on the verge of a major revolution. One question that is rarely asked is how humanoid robots will be powered. Will they have batteries? Or will they be connected to power sockets with long cables, which would restrict their freedom of movement? And if such robots replace human workers, they will also require a new generation of "robot engineers". If we believe the experts, change will come soon.

Kerosene from waste

A British company has developed a process for producing kerosene from household waste called Firefly Green Fuels(https://flyfirefly.uk). The process starts with sewage sludge. It is then converted into an oily solid and finally into kerosene. The new fuel has been tested by the DLR Institute for Combustion Technology, which suggests that it is a perfectly acceptable aviation fuel. According to the company, each person generates enough waste to produce around 4 liters of kerosene per year. This could meet around 5% of the UK's demand. Yes, this process turns a waste product into something valuable. But should we take this seriously? That's for each reader to decide for themselves!

Going green - but how?

Everyone agrees that harvesting solar energy is a key element of any 'green strategy'. The EU recently announced plans to triple European solar capacity to 672 GW by 2030. As part of the EU's Green Deal Industry Plan, 40% of solar panels should be manufactured here in Europe. But unfortunately, the manufacture of solar panels in Europe has almost completely collapsed and China now dominates the global supply of these devices. In 2023, 97% of solar panels installed in Europe came from China. In fact, Chinese manufacturers produce far more panels than they can sell. The European Solar Manufacturing Council (ESMC) has warned of an almost complete collapse of the industry. The Dutch company Exasun filed for bankruptcy in January of this year and the Austrian company Energetic is also in difficulties. Global solar installations currently amount to around 400 GW/year. Chinese production of solar modules is around 1100 GW/year. It is estimated that the stock of solar modules in European warehouses awaiting installation is around 90 GW. In China, the largest manufacturer of solar modules, Longi, recently announced that a third of its workforce would lose their jobs. The cost of solar modules has more than halved since 2015, from around 1.5 million euros/MW to 650,000 euros/MW today.

In large parts of Europe, the construction of solar parks is rejected because it means the loss of agricultural land. However, in the Middle East and India, solar parks are being built in deserts, i.e. on land that would otherwise not be used. Figure 4 shows part of India's Bhadla solar farm, which covers 56 km2 and produces around 2.2 GW, making it one of the largest in the world. All in all, it's a strange situation. Solar modules have a lifespan of around 20 years and there will come a time when, here in Europe at least, the market is saturated and manufacturers will have to cut back production, as is already the case in China. Will we ever be able to rebuild the industry in Europe, perhaps with the help of robots, to compete with the low labor costs in China? But - as Figure 5 shows - the Chinese are already using robots to produce solar cells. As one European expert said: "That ship has sailed".

"Green" ammonia

The Haber-Bosch process, in which nitrogen and hydrogen are converted to ammonia, is around 110 years old. It is undoubtedly one of the most important chemical processes in the world and without the fertilizers produced from ammonia, it would not be possible to feed the world's population. However, the process also releases a lot ofCO2 - perhaps 2% of global greenhouse gases. This is why attempts are being made worldwide to produce ammonia using alternative methods. Renewable energies are by definition discontinuous, and if the Haber-Bosch process is not operated continuously, the catalyst used will decompose. Although ammonia is an important component of fertilizers, it has been increasingly recognized as a fuel or energy storage medium in recent years. The production of "green" ammonia is therefore more important today than ever before. Numerous companies are developing ways to produce "green" ammonia. Who knows which of them will be successful? One of them is Starfire Energy(www.starfireenergy.com), based in Colorado, USA. Its method consists of producing hydrogen by electrolyzing water and then reacting it with nitrogen in a honeycomb reactor equipped with catalysts. Another company is Atmonia(https://atmonia.com), based in Finland. Its process consists of a single electrochemical reduction of nitrogen and the production of hydrogen. Jupiter Ionics(https://jupiterionics.com) is based in Australia and uses the so-called. MacFarlane-Simonov electrolyzer. Water is added to one side, nitrogen to the other, and ammonia is produced. Lithium nitride is used as a moderator. Several of these projects are housed in a standard container. These are just a few of many projects of this type. Ammonia as a fuel is the subject of numerous R&D projects.

Conclusion: The future may not only be determined by electricity generation and storage, but also by an "ammonia economy".

"On the use of ammonia as a fuel - A perspective", Fuel Communications, Volume 11, June 2022, 100064

"Ammonia as a potential marine fuel: A review", K Machaj et al, Energy Strategy Reviews, Volume 44, November 2022, 100926

"Nitrogen reduction to ammonia at high efficiency and rates, based on a phosphonium proton shuttle", Suryanto, B. H. et al, Science, Vol. 372, No. 6547

Buried treasures

Since the beginning of civilization, we have extracted from the earth the materials we need for our civilization. Metals, from gold to iron, and non-metals such as coal and oil. This also includes gas, such as natural gas and - although it is hardly known - helium, which is found in East Africa. But now a completely new search and a new technology is emerging: the extraction of hydrogen from underground rock. Gentech, a company based in London(https://hydrogengentech.com), is mapping deposits around the world and plans to extract hydrogen from them. Hydrogen can be found trapped in certain rock layers, particularly in ophiolites. Such deposits are known to exist in Oman, Mali, the central and southern parts of the USA and the UK. Another company, Gold Hydrogen, has discovered H2 deposits on the Yorke Peninsula in South Australia. Earlier this year, the US company Koloma(https://koloma.com), which is funded by Bill Gates of Microsoft, also entered this business. According to the US Geological Survey Department, the so-called "white hydrogen" could last for hundreds of years. This whole concept could change the global energy scene - or prove to be a dead end. We may find out the answer in 2-3 years.