Microplastic pollution

Scientists in Oldenburg have taken a closer look at microplastic pollution in the German Bight of the southern North Sea. Using pyrolysis-GC/MS, different types of plastic were analyzed in samples taken from different locations at a depth of 2.5m. The concentration of microplastics (MP) ranged from 2-1396 μg.m-3 and was not homogeneous. Both meteorological and oceanographic locations had an influence on the concentration. Water samples taken from the vicinity of important shipping lanes were contaminated with plastic particles originating from binders used in ship paints. Dr. Barbara Scholz-Boettcher, who led the research, regards these as a kind of "marine skid marks".

The plastic particles were filtered out of the seawater using stainless steel sieves with a diameter of less than one millimeter. In addition to the particle numbers, the mass distribution was determined for the first time. Samples from the coast showed packaging-like polymers. The "marine skid marks" had microparticles of chlorinated rubber, acrylic-styrene polymers and epoxy binders. All known polymers (PE, PP, PS, PET, PVC, PMMA and PC) were detected.

The plastic particles were filtered out of the seawater using stainless steel sieves with a diameter of less than one millimeter. In addition to the particle numbers, the mass distribution was determined for the first time. Samples from the coast showed packaging-like polymers. The "marine skid marks" had microparticles of chlorinated rubber, acrylic-styrene polymers and epoxy binders. All known polymers (PE, PP, PS, PET, PVC, PMMA and PC) were detected.

Until now, it was assumed that 80% of MP pollution in the sea consists of terrestrial waste and 20% of marine litter. The new research calls this assumption into question.

Environ. Sci. Technol. 2021, 55, 4, pp. 2285-2295 ; https://www.presse.uni-oldenburg.de/mit/2021/025.html

Precious metal recovery

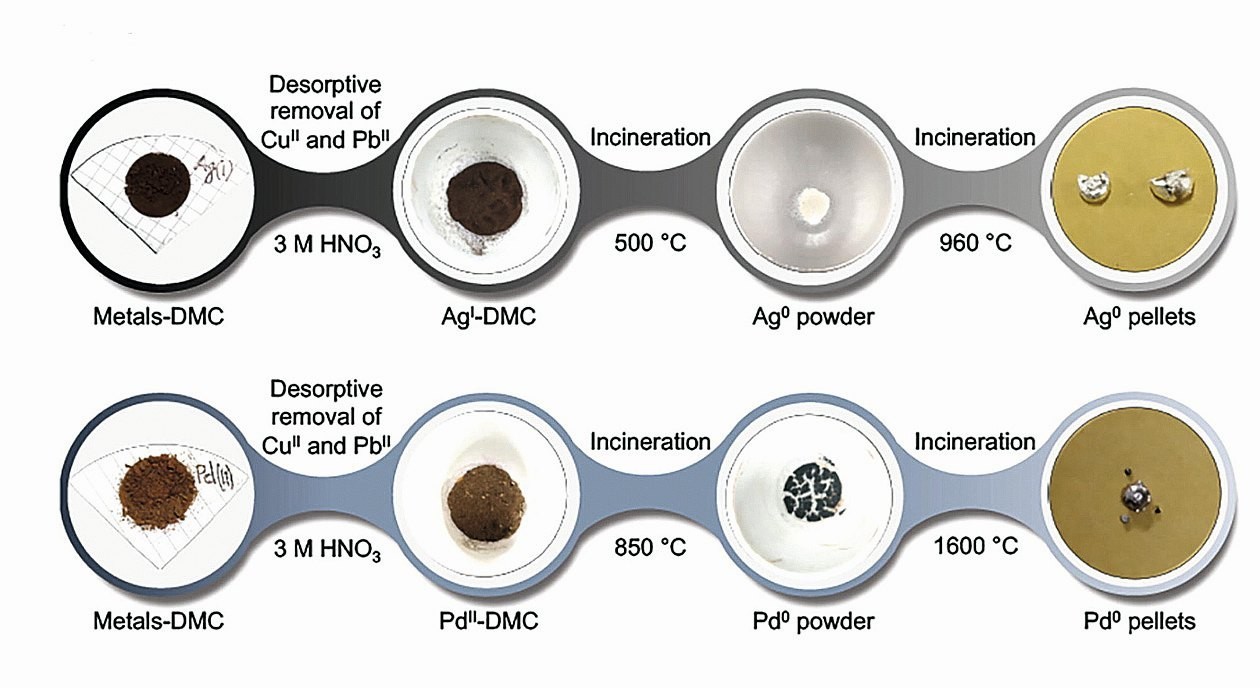

Scientists from Japan and Bangladesh have chemically modified cellulose to develop a new adsorbent for the uptake of precious metals from wastewater. The thiocarbamate-modified pulp was able to selectively remove silver (I) and palladium (II) from acidic wastewater using chelation. The adsorption capacities for silver and palladium were 10.97 mMol.g-1 and 4.28 mMol.g-1 respectively. Subsequently, the metals could be recovered by simple incineration with a purity of over 99 %.

No toxic eluents or reducing agents were used in the process described. According to the authors, the process is scalable.

Chem. Eng. J. 2021, 407, 127225 ; https://doi.org/10.1016/j.cej.2020.127225

Aqueous zinc ion battery

Aqueous zinc ion batteries (ZIBs) are being intensively researched because they are safer and more cost-effective. If the zinc coating on the anode is not uniform, this often leads to uncontrolled dendrite growth. The internal resistance increases and the battery is no longer functional. In a collaboration between scientists from Dresden and Dalian, it was found that a silver coating on metallic zinc is capable of enabling uniform galvanization. The electrolytic wettability of Ag-coated zinc is better than that of zinc alone. The slight overpotential and the fast coating dissolution kinetics of zinc also contribute positively to this.

Thanks to the Ag coating, the zinc anode can withstand up to 1450 hours of repeated plating/stripping at low overpotential. In combination with a V2O5-based cathode, the positive effects were confirmed.

ACS Appl. Mater. Interfaces 2021, 13-14, pp. 16869 - 16875 ; https://doi.org/10.1021/acsami.0c22911