Wabtec Corporation, originally founded in 1869 by Thomas Edison, Louis Faiveley and George Westinghouse as the Westinghouse Air Brake Co., has made one of the largest foreign direct investments in the railroad sector in India. Wabtec, whose manufacturing capacity in India has grown, plans to make India the manufacturing hub for exporting diesel locomotives, electrical components and a range of other products. Wabtec has a diesel locomotive manufacturing facility in Marhowra in the northern state of Bihar and a third of its global engineering team is based in India.

The team tests components, digital solutions, track maintenance and electrification across national borders. Wabtec also has two locomotive maintenance workshops in Roza, Uttar Pradesh and Gandhidham, Gujarat and several other locations across the country. Wabtec's India Technology Center was inaugurated in Bengaluru in October 2021. In January, the railroad friction business was acquired from Masu for $34 million to strengthen the braking business. The company currently supplies braking systems for Indian locomotives and LHB wagons.

ZF expands in India

The ZF Friedrichshafen Group has committed to investing more than EUR 200 million in the commercial vehicle division in India over the next ten years. It will set up a new production facility in Orgaddam on the outskirts of Chennai, which has been selected for the Indian government's Production-Linked Incentives program.

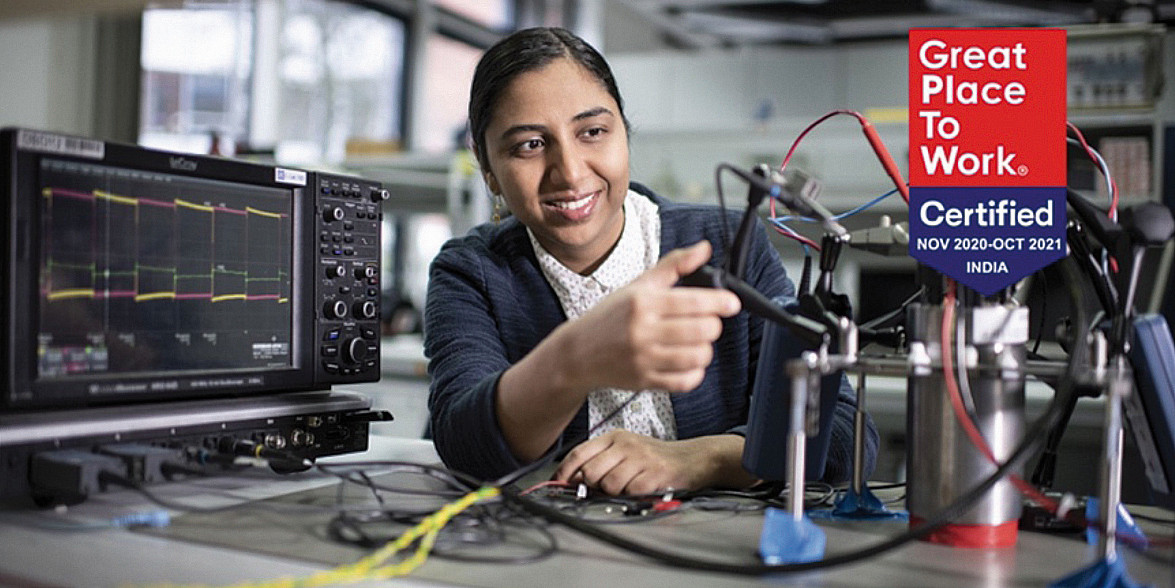

ZF employs many thousands of people in India, including software engineers

ZF employs many thousands of people in India, including software engineers

ZF already employs 6500 people in India across all business units. For the Commercial Vehicle (CV) division alone, ZF has hired 300 software engineers who will play a critical role in the future of mobility, and the company is in the process of setting up a new plant to grow in this decade.

All-in-one coating system from Sifco

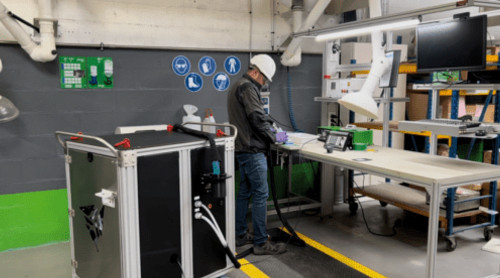

Portable all-in-one coating systemSifcoASC from Independence, Ohio, also operates in Ahmedabad, India, with Sifco India. The global player in the field of selective electroplating has launched the Advanced Solution Control System (ASCS), a new portable all-in-one coating system with drip-free technology.

Portable all-in-one coating systemSifcoASC from Independence, Ohio, also operates in Ahmedabad, India, with Sifco India. The global player in the field of selective electroplating has launched the Advanced Solution Control System (ASCS), a new portable all-in-one coating system with drip-free technology.

Thanks to drip-free selective plating, all chemical solutions flow through the so-called SmartTools and soak up before being returned to the trolley's solution management system - directly on the surface of the workpiece. The result is a cleaner, more environmentally friendly and inherently safer working environment.

This innovative system is fully transportable and can be taken directly to the part or component in question. As well as increasing throughput and productivity, the reduced ergonomic risk also offers major safety benefits for operators and employees. Exposure to fumes and chemicals is significantly reduced and the amount of waste is reduced as fewer covers, masking materials and cleaning agents are required. With increased automation, cycle times can be optimized, data is recorded in real time, repeatability from one technician to the next is increased and human error is minimized.

The ASCS is currently available in two sizes, Nano and Prime. Both have been developed to further enhance the existing benefits of selective coating, including in-situ repairs and reduced masking and downtime. Designed for simple jobs with two or fewer process steps, the manual Nano uses the TechnoPlate with its detachable controller that allows technicians to continuously monitor current and voltage levels without having to turn around. Recommended applications include anodizing, zinc-nickel, cadmium and passivation.

The Prime, an extension of the Nano, is suitable for more complex applications and can accommodate up to nine different plating solutions. This fully automated system is equipped with an HMI-controlled rectifier that allows technicians to program each process step, continuously monitor operations and log data in real time. The trolley also has a unique cleaning-in-place feature that prevents the potentially harmful mixing of chemicals. The Prime takes up the footprint of a standard pallet.

Sifco tools cover a variety of geometries and contact areas, ranging from 0.07 dm2 to 1 dm2. Various drip-free anodes have been developed for this purpose. With the patent-pending SmartTools, unlike the conventional brush plating process, the deposit can be plated in any orientation - horizontal, vertical and upside down - without changing the performance or result. The tools can be combined to build infinitely shape-changing, scalable electrodes to suit even the most specific plating applications.