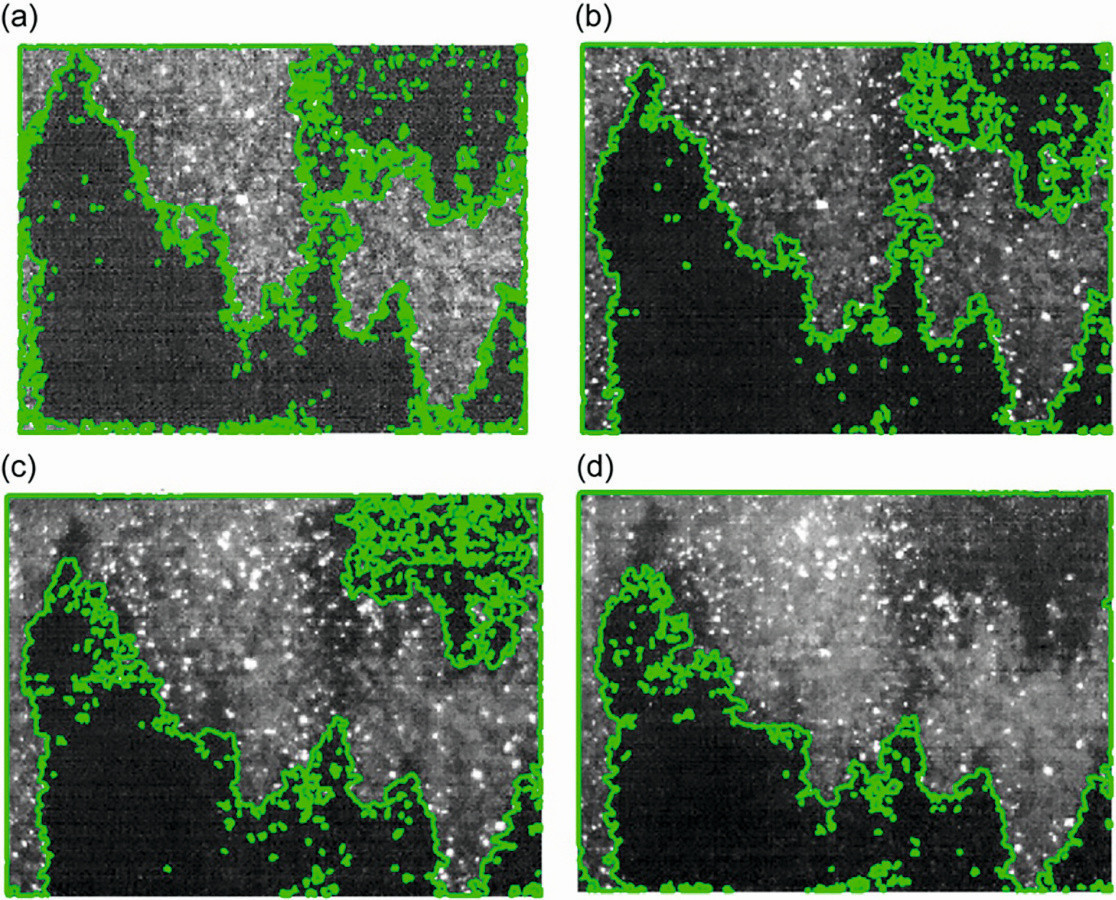

Primer corrosion starts when the coating fails and the cause is hidden and usually not visible during a visual inspection. Under mechanical or thermal stress, micro-defects slowly spread through the coating and eventually reach the substrate, exposing it to the environment and leading to accelerated corrosion and flaking or peeling of the coating. Non-destructive testing methods such as eddy current measurement, radiography, near-field microwave measurement and thermography are used to detect and quantify undercoat corrosion. In the case of thermography, the inspection relies on highly qualified personnel to analyze the images for defects and, in the case of corrosion, to assess its growth (Fig. 1).

Fig. 1: Processed thermal images of a painted sample stored in saline solution for (a) 6 days, (b) 8 days, (c) 13 days and (d) 15 days

Fig. 1: Processed thermal images of a painted sample stored in saline solution for (a) 6 days, (b) 8 days, (c) 13 days and (d) 15 days

Scientists at the University of Waikato in New Zealand have developed a method for the automated detection and quantification of the onset and growth of underbody corrosion using impulse thermography. Using a novel algorithm, corrosion was automatically detected in a large number of structural steel samples exposed to three different corrosive environments. Using thermal images captured by a microbolometer infrared camera, the method was able to accurately and reliably detect, quantify and monitor the growth of corrosion under coatings. The extent of corrosion was reported with an accuracy of 3% absolute deviation compared to the actual extent.

The new method could not accurately detect the extent of corrosion in samples with blistering under the coating. In such cases, it is assumed that the coating has failed. The blisters should be identified from the thermal data or by visual inspection and the coating repaired rather than following the progression of corrosion. Pulse thermography allows for a more comprehensive inspection of components as a highly skilled operator no longer needs to inspect a large data set.

100 years of SKF in India

Fig. 2: Sven Wingquist, inventor of the double row self-aligning ball bearing

Fig. 2: Sven Wingquist, inventor of the double row self-aligning ball bearing

Aktiebolaget Svenska Kullagerfabriken was founded on February 16, 1907 in Säve Strandgata, Gothenburg. Sven Wingquist, inventor of the double row self-aligning ball bearing, was one of the founding members and the first managing director (Fig. 2). As early as 1912, a representative was appointed in India and in 1923 a branch office was opened in Calcutta, which also covered Burma (now Myanmar). SKF is currently celebrating its 100th anniversary in India. As a leading supplier of bearings and units, seals, lubrication, condition monitoring and services, SKF plays an important role in the industry (not only) in India. The company now employs 2600 people in India, operates six production sites, eight distribution centers and four factories as well as a nationwide network of suppliers and dealers. In addition, SKF has a Global Technical Center in India for end-to-end technical and technological solutions.

Events in India

The Indian Paint Association (IPA), the apex body of the Indian paint and coatings industry, which generates around USD 8 billion in revenue, organized the Indian Paint Conference in Goa in January 2023, the largest trade event in the Indian paint and coatings industry. The IPA conference takes place every two years. Around 700 delegates and more than 40 panelists, including leading businessmen, technology specialists and other professionals, shared their views on a range of relevant topics in the industry. The aim was to develop a strategic approach for the sustainable growth of the sector in today's dynamic times.

The Surface & Coating Expo of the Confederation of Indian Industry is yet to come. It is India's largest and most exclusive event focusing on surface engineering, preparation, coatings, finishing, corrosion protection, environmental engineering and technologies. The 4th edition of Surface & Coating Expo 2023 (SCE2023) will be held from June 29 to July 1, 2023 at Chennai Trade Centre. A 2-day International Conference on Surfaces and Coatings and a 2-day Technology Conference on Electroplating will be the focal points of this highly prestigious event.

Miscellaneous

India is now one of the top ten countries for the installation of industrial robots. Within five years, the number of industrial robots in operation has more than doubled and now stands at more than 40,000 units. This corresponds to an average annual growth rate of 16% since 2016. Robot density, which measures the number of industrial robots per 10,000 workers, reached 148 in 2021. In addition to the automotive industry, other major buyers of robots include the metal industry, the rubber and plastics industry and the electrical and electronics industry. Further figures: India has 759 million active internet users per month, and their number is expected to reach 900 million by 2025.

Car manufacturers see high growth potential in the Indian market for electric vehicles. Mercedes-Benz, India's largest luxury car brand, expects battery electric vehicles to account for 25% of total sales in India by 2027. However, only five of the ten largest Indian car manufacturers offer electric cars, including Tata, Hyundai, Mahindra, Kia and MG Motors.