Shot peening is an established surface treatment process that improves the properties of components that are exposed to high alternating loads. Surface treatment processes such as bending, milling, grinding or heat treatment processes cause residual tensile stresses that lead to a shorter service life of the components. If the residual tensile stresses are transformed into residual compressive stresses with shot peening, this leads to a significant increase in service life and the maximum load properties are considerably improved.

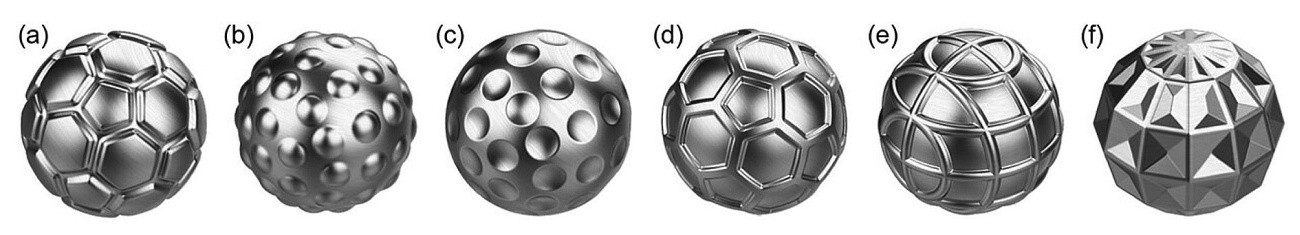

Fig. 1: The proposed designs of the AM-manufactured shots: a) soccer ball, b) multibumps, c) golf ball, d) icosahedron, e) lattice and f ) with square pattern

Fig. 1: The proposed designs of the AM-manufactured shots: a) soccer ball, b) multibumps, c) golf ball, d) icosahedron, e) lattice and f ) with square pattern

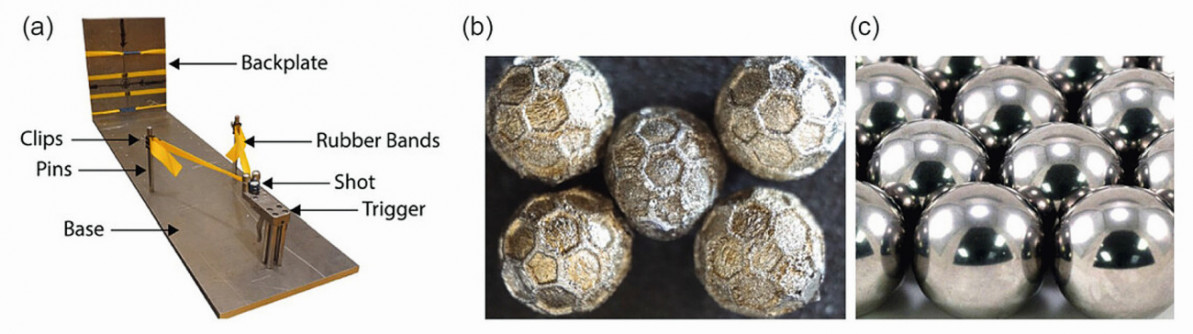

Engineers at the Polytecnico di Milano in Italy have developed a new method of surface patterning using customized additively manufactured shots based on the conventional shot peening process. Customized spheres are designed and their surface texturing capability on acrylonitrile butadiene styrene (ABS) polymer substrates is investigated. A finite element model was developed to bombard the substrate with customized AISI 316 stainless steel spheres. The unique textures produced were compared qualitatively by visual inspection and quantitatively using standard surface roughness parameters (Figs. 1 and 2). To prove the concept, tests were conducted in which the ABS sheets were treated with a custom shot and a ball shot. The results underline the great potential of the shot peening process, in conjunction with additive manufacturing, for customizing the abrasives used for surface texturing of polymer materials.

Fig. 2: a) Centrifugal system used for the preliminary tests, b) Special icosahedron spheres (diameter of approx. 8 mm) produced by laser powder bed fusion (LPBF) in their AB state, c) Stainless steel ball bearing (diameter of 8 mm)

Fig. 2: a) Centrifugal system used for the preliminary tests, b) Special icosahedron spheres (diameter of approx. 8 mm) produced by laser powder bed fusion (LPBF) in their AB state, c) Stainless steel ball bearing (diameter of 8 mm)

The authors assume that the result of this study opens the view to the development of a new, flexible, economically and ecologically sustainable process for surface structuring and functionalization.

Adv. Eng. Mater. 2023, 25, 2201730

Aluminum thin film deposition

Supercapacitors are capable of storing very large amounts of electrical charge. They are one of the most promising electrochemical energy storage devices to complement rechargeable batteries. The state of the art is based on widely available and relatively cheap active materials and electrolytes, i.e. activated carbon and inorganic salts such as tetraethylam monium tetrafluoroborate (TEABF4) dissolved in organic solutions, usually acetonitrile (ACN). These combinations guarantee an operating power of 10 kW kg-1 and more.

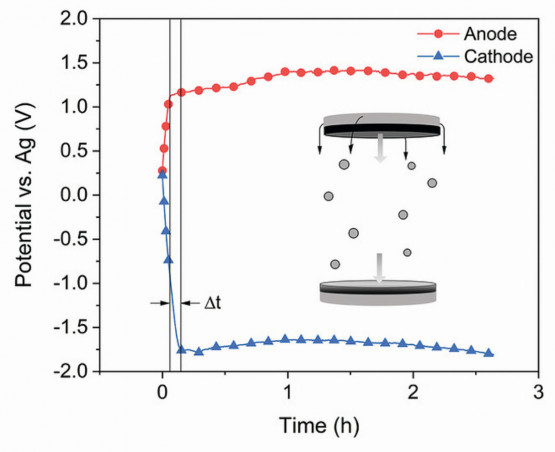

Scientists in Turin and Jena have jointly addressed a new finding observed when performing aluminum dissolution experiments to study the stability of supercapacitors (SCs). Supercapacitor (SC) electrodes based on carbon-coated aluminum foils were electrochemically investigated under harsh conditions in an electrolyte based on bis-trifluoromethylsulfonylimide (TFSI), due to their high chemical and thermal stability, and with acetonitrile (ACN) as solvent. During the subsequent deposition on the carbonaceous surface of the counter electrodes, the dissolution of aluminum was observed. The process could be reproduced on standard SC activated carbon electrodes (Fig. 3).

Fig. 3: Al dissolution experiment with activated carbon electrodes as anode and cathode in 1 N Al(TFSI)3 in ACN. The current density was 0.5 mA g-1

Fig. 3: Al dissolution experiment with activated carbon electrodes as anode and cathode in 1 N Al(TFSI)3 in ACN. The current density was 0.5 mA g-1

Currently, Al is deposited with baths of low melting point aluminum halides such as AlCl3 or AlBr3, either in mixture with some metal hydrates or in non-polar solvents. These present many limitations in practice. The development of halogen-aluminate-free electrolytes opens up the possibility of developing safer and more cost-effective processes for aluminum plating, which remains a good technological solution for developing coatings against corrosion, improving wear resistance and surface aesthetics. However, according to the authors, deeper insights into the deposition mechanism on the carbon surface need to be gained in order to better utilize the observed phenomena, possibly also as an alternative to copper.

Adv. Mater. Interfaces 2023, 10, 2202470

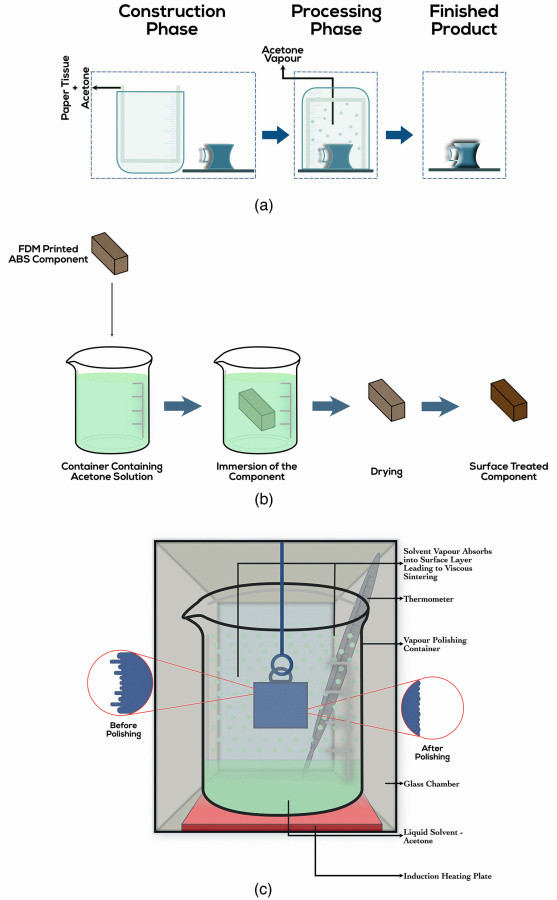

Fig. 4: Steam polishing techniques, (a) phases of cold steam polishing, (b) immersion technique of steam polishing, (c) hot steam polishing

Fig. 4: Steam polishing techniques, (a) phases of cold steam polishing, (b) immersion technique of steam polishing, (c) hot steam polishing

Steam polishing of 3D-printed parts

The market share of 3D printing has grown exponentially since 2014. It is estimated that the 3D printing market is expected to grow from USD 15 billion in 2023 to USD 34.5 billion in 2028, with an annual growth rate of around 18%. Fused deposition modeling (FDM), one of the most widely used additive manufacturing processes in the industry, involves depositing molten material in layers to create a 3D structure. These 3D-printed parts must then undergo post-processing to improve the surface quality. For polishing an FDM part, the most commonly used options are sanding or vapor smoothing. One of the best methods for improving the surface quality is chemical treatment with cold steam. Post-processing of samples by chemical vapor polishing is a superior technique that is also suitable for complex geometries. With this process, parts can be printed at a lower resolution and then polished with chemical vapor polishing to improve the production rate and quality of the finished 3D printed parts. Chemical vapor polishing has the potential to make FDM printing more reliable, cost-effective and marketable for use in commercial applications and new product research and development (Fig. 4).

In a joint review article, scientists and engineers from Germany, India and Singapore have described the state of the art and future prospects.

Progr. Additive Manuf. https://doi. org/10.1007/s40964-022-00391-7