Artificial intelligence

Almost every day we read something about AI (artificial intelligence) in our newspapers. Sometimes exciting new developments, sometimes "horror stories". Should we be happy or afraid? How will this affect our personal lives, our work and our careers, and how will it affect our industry - and the Galvanotechnik magazine that arrives in our mailbox every month? One thing is clear, AI technology is evolving on an almost weekly basis. But already we are seeing some important benefits, not least in the field of medicine. AI is now being used extensively to interpret X-rays and other medical scans.

These are usually taken by a medical technician who then passes the results on to a highly qualified radiographer who interprets them. With the help of AI, the radiographers now interpret the scans more accurately and also much faster. In large hospitals, the workload of radiographers is reduced and scans are processed much faster - good news for patients. So fewer radiographers are needed, and perhaps one day they will be completely replaced by AI. Understandably, therefore, they have mixed feelings about the impact of AI in their industry. AI is also bringing change to other areas of medicine. Across the Atlantic, in Hollywood, where actors and screenwriters have been on strike for many weeks. Partly - as usual - it's about pay. But they are also concerned because it is now clear that AI can not only write scripts but also create - or should we say recreate - actors who died many years ago. It seems quite possible to produce an entire movie on a computer without the need for actors, a film studio or hundreds of men and women to operate the cameras, create the lighting, costumes and much more. I'd like to mention another area where AI is already having a huge impact - the legal profession. When we think about this profession, we realize that it rests on two pillars. The first pillar is the law itself, as laid down in the constitution of each country or in international law. The second pillar is "legal history" - the way judges have interpreted these laws in the past. This is usually referred to as "precedent". AI is the perfect tool here. It can be fed with the law as written in the constitution and with "legal history" - the results of court cases going back perhaps 100 years. Many lawyers can already use AI and, for example, issue a legal "opinion" in just one hour. In the past, it might have taken a week to search legal databases on a computer. I could give many other examples, and it seems obvious that in certain areas some jobs will simply disappear.

AI and electroplating

And what about our industry? I believe that AI will have a rather minor impact. In the "front office", tasks such as dealing with customers, preparing price quotations for new orders, ordering materials and even answering phone calls or emails could be largely or completely automated. In the laboratory, AI will help to interpret test results, e.g. micrographs. Using data from electroplating baths and others, it will predict how bath solutions should be controlled. But in actual production, where much is already automated, hardly any significant changes are to be expected. And last but not least: How might AI affect the magazine we value so much? AI has two elements. The first is the enormous database on which it is based. Countless billions of documents are stored there. Newspapers, magazines, legal and medical documents and much more. The second element is the ability of AI not only to search this database, but also to interpret the data and draw conclusions from it. The data is not just text, but also images and sounds - such as the voices of many well-known people. This can be used to create new images or - using the voice of a famous person - show how they speak and say things they have never said. The criminal potential of artificial intelligence is enormous. But - back to our magazine. Most of the content of a Galvanotechnik magazine is 100% new. It is not (until a few weeks later) added to the huge databases of AI. Every now and then there are review articles in Galvanotechnik, and - yes - KI could perhaps be used to create them. But even then, such reviews need a "stage" - i.e. our magazine. Likewise, advertising is usually 100% new and it's hard to imagine how AI could change that. One last word. AI is truly amazing - but sometimes it can get pretty crazy and create text that is largely wrong or completely wrong. It can lie! No doubt this will improve, but for now all experts agree - the output of AI-generated text should be treated with caution and should always be checked by a real human.

Bottom line: AI will lead to the loss of some jobs (and the creation of new ones), but it seems unlikely to bring major changes to our industry or the plating magazine that serves it. On the contrary, AI could be a useful tool for all of us.

tool for all of us.

Hydrogen in the news

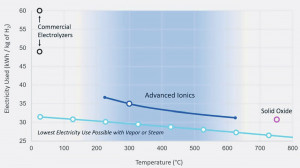

Hydrogen, most of us believe, is the fuel of the future. But how will it be produced? There are various projects planned or under construction that use natural gas as a feedstock and convert it into hydrogen andCO2, which is then transported away via pipelines and stored in an underground or undersea reservoir. As this technology can only work on a large scale, such projects are designed as a hub at the center of the chemical or metallurgical industry, so that different companies could be supplied from a hydrogen hub in an industrial park. There are now many new developments in the field of electrolytic hydrogen plants. Most of them use so-called PEM technology - proton exchange membranes. IMI Vivo(www.imi-critical.com/brands/imi-vivo) now offers skid-mounted container units in the 0.1 to 1.5 MW range. The power consumption is specified as > 60 KWSt/kg H2. A company called ITM Power(www.itm-power.com/products/poseidon) has been manufacturing PEM electrolyzers for several years. A few weeks ago, it launched a new 20 MW unit, the so-called "Poseidon" - probably the largest of its kind in the world (Figure 1). Fig. 2: Energy requirement for hydrogen production

Fig. 2: Energy requirement for hydrogen production

At higher temperatures

A US manufacturer, Advanced Ionics Inc(www.advanced-ionics.com/technology) based in Milwaukee, has developed a new technology that operates in the > 100 °C range and uses waste heat in the form of steam from other processes on site. In this way, they claim to be able to produce H2 at < 35 kWh/kg, perhaps even 30 kWh/kg. Figure 2 is from a presentation at the CERAWeek conference earlier this year. It shows (top left) typical energy requirements for PEM electrolyzers. Also, data for the new Advanced Ionics technology and (at the bottom) the lowest possible energy based on thermodynamic calculations. At the bottom right is a single data point for high temperature solid oxide. The basis of the technology is not clear to me. US patent US10253421 is a general description of the Advanced Ionics technology. However, the company states that its new technology does not use membranes, nor does it use precious metals such as Pt or Ir. I will not discuss the high temperature solid oxide hydrogen electrolyzers, because as far as I know these are mainly still in the development stage. The world's latest hydrogen technologies will be presented and discussed at the Hydrogen Technology Conference & Expo in Bremen on September 27 and 28.

JCB makes a decision

JCB is one of the world's largest manufacturers of mechanical excavators and similar earthmoving equipment. All of these machines are currently powered by diesel engines. It is clear that they - like all other companies of this type - need to find an alternative. So they tried batteries, fuel cells (using hydrogen) and developed their own hydrogen fuel engine. They came to the conclusion that the latter was the only realistic solution for all but the smallest machines. The new hydrogen fuel engines will be commercially available in a few months. Figure 3 shows a hydrogen-powered excavator. How is it refueled? The company also offers a hydrogen refueling truck. It will be interesting to see what other companies like Caterpillar decide. Fig. 3: Hydrogen-powered excavator

Fig. 3: Hydrogen-powered excavator

Vietnam conquers the world market

A few years after the Second World War, we in Europe were offered Japanese-made cars for the first time. A few years later, Korean cars entered the European market. More recently, China has become a serious player. It is perhaps strange that the USA - until recently the largest car manufacturer in the world - has never played a role in the European market. Russian cars were available in Europe for a few years, but for many they were nothing more than a bad joke. Now Vietnam is trying to gain a foothold in our markets for the first time. The Vietnamese company VinFast was launched on the New York Stock Exchange a few weeks ago and valued at an almost unbelievable 85 billion US dollars - more than Ford (48 billion US dollars) or GM (46 billion US dollars). VinFast is controlled by one man - Pham Nhat Vuong, who owns around 99% of the shares. VinFast stated that it sold 11,300 units in the first six months of 2023. By comparison, Tesla sold around 900,000 cars in the same period. Figure 4 shows one of the company's main models, the VF6. Vinfast only builds electric vehicles. The company also offers the VF8 and VF9 models. What can be said about this? If the company succeeds, it is certainly bad news for China. But it is not good news for our European manufacturers either.

Fig. 4: The new Vietnamese VF 6 EV from VinFast

Fig. 4: The new Vietnamese VF 6 EV from VinFast

An energy-saving coating

As we "go green", an inevitable consequence is that we will see more and more high-voltage power lines in our landscape - and no one claims that they are beautiful. True, the technology exists,

underground - but (per km) - it is many times more expensive. So we have to accept these masts and cables as part of modern technology. The temperature of the cables is often above the ambient temperature. Partly because of ohmic heat and partly because they absorb solar energy. And as we all know, the resistance of a metallic conductor increases with increasing temperature.

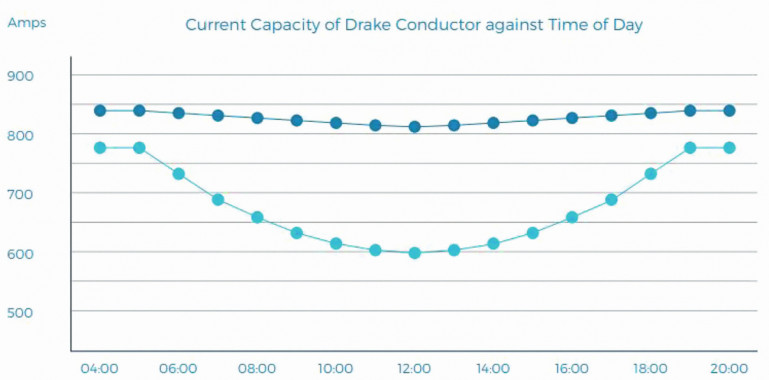

As Figure 5 shows, such heating reduces the current-carrying capacity of these high-voltage lines and means we need more cable or thicker (and heavier) cable. The company AssetCool(www.assetcool.com) has developed a photonic nanocoating that works in two ways: firstly, it increases the reflectivity of the cables, reducing solar heating. Secondly, it increases the heat loss of the cables. Both lead to a reduction in the temperature of the cables under all conditions. Under unfavorable conditions, the output of a high-voltage cable can be reduced by around 20 %. As Figure 5 shows, this is almost completely eliminated by the new coating. The company has also developed processes for coating existing cables. The company has applied for several patents, which can be viewed at Espacenet(https://worldwide.espacenet.com). All are assigned to Cable Coatings Ltd.

Fig. 5: Upper curve - coated, lower curve - uncoated cable. Power output over the course of the day

Fig. 5: Upper curve - coated, lower curve - uncoated cable. Power output over the course of the day

1. overhead line with superhydrophobic coating

WO2021181076A1 - 2021-09-16 -

A single coated conductor for an overhead power transmission or distribution line is provided, comprising one or more electrical conductors and a first coating provided on at least a portion of the one or more electrical conductors. The first coating comprises: an inorganic alkali metal silicate resin; an optically active element; and a superhydrophobic agent. The first coating has an average heat emission coefficient E ≥ 0.90 over the infrared spectrum 2.5-30.0 µm and an average solar reflectance coefficient R ≥ 0.80 and/or an average solar absorption coefficient A ≤ 0.20 over the solar spectrum 0.3-2.5 µm.

2. composition for coating an overhead conductor

WO2021152311A1 - 2021-08-05 -

A composition for coating an overhead conductor is disclosed comprising: a reflective agent; a photocatalytic agent comprising ≥ 70% by weight of anatase titanium dioxide (TiO2) having an average particle size ("aps") ≤ 100 nm; a polyorganosiloxane binder; and a superhydrophobic agent comprising either: surface functionalized silica nanoparticles, a functional polysiloxane, or a polymethylsilsesquioxane.

3. overhead ladder with self-cleaning coating

US11174398B2 (A1) - 2021-11-16 -

A single coated conductor for an overhead power transmission or distribution line is provided, comprising one or more electrical conductors and a first coating provided on at least a portion of the one or more electrical conductors. The first coating comprises: an inorganic binder comprising an alkali metal silicate; a polymerization agent comprising nanosilica ("nS") or colloidal silica (SiO2); and a photocatalytic agent, wherein the photocatalytic agent comprises ≥ 70 wt% anatase titanium dioxide (TiO2) having an average particle size ("aps") ≤ 100 nm. The first

coating has an average heat emission coefficient E ≥ 0.90 over the infrared spectrum 2.5-30.0 μm and an average solar reflectance coefficient R ≥ 0.90 and/or an average solar absorption coefficient A≤0.10 over the solar spectrum 0.3-2.5 μm.

4. composition for coating an overhead conductor

WO2021105673A1 - 2021-06-03 -

A composition for coating an overhead conductor is disclosed, comprising: a reflective agent; a photocatalytic agent comprising ≥ 70% by weight of anatase titanium dioxide (TiO2) having an average particle size ("aps") ≤ 100 nm; a non-aqueous solvent; and (iv) one or more alkyl silicate binders.

5. composition for coating an upper conductor

WO2022003096A1 - 2022-01-06 -

The present invention provides a composition for coating an overhead conductor comprising: a binder comprising a solvent and silica, organically modified silica, titania, alumina, zirconia, iron oxide, or a combination thereof; and a corrosion inhibitor.

Storing energy - in concrete!

There seems to be a consensus that a means of storing energy is essential when using renewable energy. Lithium batteries are expensive, sodium batteries only slightly cheaper. What about supercapacitors? A team of scientists at Harvard and MIT led by Prof. Franz-Joseph Ulm (former graduate engineer, TU Munich) has developed a supercapacitor made of concrete mixed with carbon black. As the cement mixture hardens, water is absorbed, leaving a branched network of tunnels that are filled with carbon black. The end result is that the cement paste is criss-crossed by conductive, wire-like tunnels that create a very large surface area. But the overall volume of the electrode remains the same. The team found that the maximum energy storage capacity depends only on the specific surface area of the carbon black. Since carbon black fills the space, the volume can easily be increased to store energy on a large scale.

In experiments, the team produced button-sized capacitors capable of storing a charge of 1 volt and found that the capacitor could maintain its storage capacity over 10,000 charge/discharge cycles with minimal loss. Three of the 1 V supercapacitors were able to light up a 3 V LED.

The team also developed button-sized capacitors with different ratios of cement to carbon black. Adding more carbon black (over 10 percent by volume) to the mix increased the storage capacity, but at the expense of the structural integrity of the cement.

Not just energy storage

Concrete is already being used to build roads, so the team believes it is also possible to use concrete storage for roads and to charge cars wirelessly while driving, similar to wireless charging pads for smartphones. Such self-charging roads already exist, but they use coils embedded in the road system and (usually) connected to an energy source. Their plan would be to harvest energy from clean energy sources and store it in the road structure.

The team estimates that a 45 cubic meter supercapacitor could store 10 kilowatt hours of energy - equivalent to about a third of the daily electricity consumption of an average U.S. household. The next step in their program is to connect units in series to form a 12-volt power source.

Carbon-cement supercapacitors as a scalable bulk energy storage solution N. Chanut et al, published: July 31, 2023, Proceedings National Academy of Science. Vol. 120 (32), https://doi.org/10.1073/pnas.2304318120

Energy from wastewater

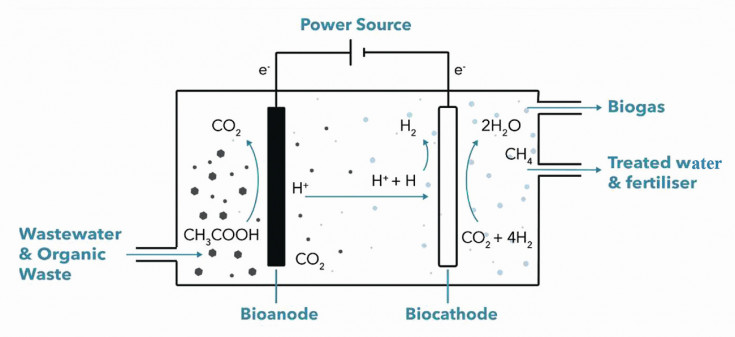

Wase(www.wase.co.uk) is a small company that has developed a technology to produce methane from wastewater containing organic molecules in an electrolytic cell. Figure 6 shows the process.

Fig. 6: Production of "biogas" (methane) from wastewater

Fig. 6: Production of "biogas" (methane) from wastewater

Until recently, the only technology for treating such waste was the so-called. Anaerobic digestion (AD), a form of fermentation that took many days to work and therefore required many large tanks. The Wase technology works three times faster than AD. It is now being installed at a brewery in Sussex, UK, and is expected to be up and running by the end of this year, treating approximately 7800 cubic meters of wastewater per year. The plant will produce approximately 378 MWh per year and the biomethane produced will save approximately 100 tons ofCO2 per year. Many other projects are under development, including some in Africa.