ICONEST 2024

For the third time, an international conference on Electrochemical Science & Technology, called ICONEST 2024, was held in New Delhi from September 18 to 20, 2024 (Fig. 1). This conference was jointly organized by the now 60-year-old Electrochemical Society of India (ECSI), Bengaluru and the slightly older National Physical Laboratory. About 400 delegates from several countries attended.

There were three plenary sessions, 15 keynote lectures, six ECSI prize lectures and two endowed lectures, one distinguished lecture, one memorial lecture, 28 invited lectures, 106 oral presentations and about 100 poster presentations. The plenary lectures were given by Prof. Bernard Normand, University of Lyon, France, Prof. Daniel J. Blackwood, National University of Singapore, and Prof. John Irvine, University of St Andrews, UK. The conference provided a platform for the students to interact with academicians and researchers from academia and industry in India as well as some foreign speakers. Many presentations were in the areas of energy and sensors, followed by surface engineering, corrosion and metal finishing. The parallel sessions were well attended. Ten companies presented their products and services.

It is a good sign that institutes are now coming together and organizing such events. It would be a great boost for surface technology in India if the Confederation of Indian Industry, Indian Institutes of Technology, Society for Advancement of Electrochemical Science and Technology and Metal Finishers' Association of India also come together on one platform.

Ni-PTFE tampon electroplating

Ni-PTFE composite coatings are used for applications that require exceptional friction resistance and top performance in coating adhesion in addition to corrosion resistance. In many countries, Ni-PTFE coatings are approved as food-safe. Both electroless and electrolytic processes have been developed for this purpose. In a collaborative effort, scientists and engineers from the UK, USA and Spain have investigated a process for electrolytic pad coating of Ni-PTFE (Fig. 2).

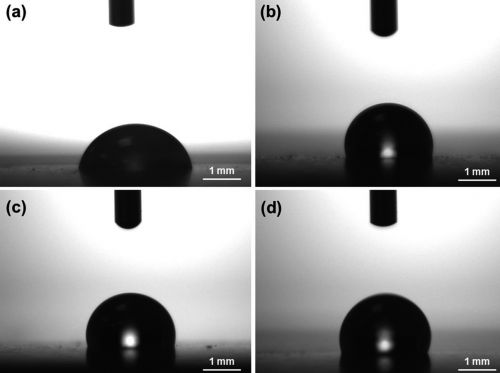

Fig. 2: Images taken while measuring the contact angle of a water droplet on the surface of different coatings: (a) Ni coating, (b) Ni/PTFE prepared with IPA, (c) Ni/PTFE prepared with ethanol, and (d) Ni/PTFE prepared with ethanol interrupted at 5 A . min

Fig. 2: Images taken while measuring the contact angle of a water droplet on the surface of different coatings: (a) Ni coating, (b) Ni/PTFE prepared with IPA, (c) Ni/PTFE prepared with ethanol, and (d) Ni/PTFE prepared with ethanol interrupted at 5 A . min

An aqueous high-speed nickel bath and PTFE microparticles (6-9 μm diameter) were used for the investigations. The bath consisted of nickel sulphate, ammonium formate, ammonium citrate and aqueous ammonia. The hydrophobic PTFE particles were suspended with various chemicals, including the cationic surfactant cetrimonium bromide (CTAB), isopropyl alcohol premixed with the particles and ethanol premixed with the particles. Inert graphite blocks and titanium nets coated with iridium oxide were used as anodes. The solution was circulated using a system developed for the deposition of metal matrix composites (MMC), which minimizes sedimentation of the particles. Although the PTFE particles could be successfully suspended with all compounds, the two alcohols produced the Ni/PTFE coating, whereas CTAB did not succeed in depositing the polymer.

The growth of the coating does not follow Faraday's law of electrolysis, as the thickness does not increase linearly with the total charge applied. The two-layer, partially intercalated structure consisted of a rough nickel underlayer covered by an outer, compact, smooth PTFE layer. The PTFE particles bind together in the valleys of the nickel coating and grow until the entire surface is covered by a polymer layer without the need for a baking phase. The resulting coating has a hydrophobic surface with a low coefficient of friction (0.10) and higher corrosion resistance in salt spray tests than the spherical nickel coating.

Nature Scientific Reports 2024,14:24069; https://doi.org/10.1038/s41598-024-71376-5

A nation mourns

Fig. 3: Ratan Tata has died at the age of 86. He led the Tata Group to its current size (Photo: Tata)The media regularly tell us who the richest people in the world or a country are. India is no exception. But missing from the list of the richest Indians was the name of a man who was not only rich but also popular. The entire nation mourned when Ratan Naval Tata passed away recently at the age of 86.

Fig. 3: Ratan Tata has died at the age of 86. He led the Tata Group to its current size (Photo: Tata)The media regularly tell us who the richest people in the world or a country are. India is no exception. But missing from the list of the richest Indians was the name of a man who was not only rich but also popular. The entire nation mourned when Ratan Naval Tata passed away recently at the age of 86.

Ratan Tata belonged to the 4th generation of the successful Tatas family. The now global group of companies was founded in 1868 and has been highly respected worldwide since its inception. Ratan Tata went to school in Mumbai and studied architecture at Cornell University. He took over the leadership of the Tata Group from Jehangir Ratanji Dadabhoy Tata (JRD Tata for short) in 1991, when India liberalized the economy and abolished the so-called "license raj", a web of state permits, regulations and bureaucracy that had paralyzed the Indian economy for many decades. Critics at the time said that he had merely inherited the position, but it wasn't long before they were proved wrong. For over 20 years Ratan Tata steered the so-called "Steel to Salt" group of companies and later for a decade in an honorary role.

He took the group abroad and over the years acquired well-known global brands such as Tetley, Corus, Jaguar Land Rover, Brunner Mond, General Chemical Industrial Products and Daewoo. India's airline Air India also went to Tata. In 2008, he launched the small, inexpensive Tata Nano car on the market, a small car project that he led with zeal and determination. An electric version of the Tata is being planned. Interestingly, the Tata Harrier and the Tata Safari SUV are produced exclusively by women. Tata was and is very important for the Indian electroplating industry, as many electroplating plants are Tier 3 or Tier 4 suppliers for Tata companies.

The fact that Ratan Tata remained true to the traditions and principles of the Group - in an environment in which so many have succumbed to the temptations of "easy money" - makes his achievements exemplary. He created more cohesion, introduced new thinking, encouraged innovation and inspired a willingness to take risks in his employees that, in hindsight, seems truly extraordinary.

In a country where economically successful people are quickly suspected of social depravity, he proved that profits can be made without sacrificing ethics and that they can be used for a good social cause. Tata's passions were fast cars, flying, scuba diving and dogs. He was also known for his social work, particularly in the fight against cancer.

www.tata.com/about-us/br />tata-group-our-heritage/tata-titans/ratan-naval-tata

Photo: ECSI