Electroless copper plating of polystyrene

When one thinks of plastic electroplating, one thinks first and foremost of ABS, whose industrial relevance is very high. The metallization of polystyrene has been less researched. Polystyrene is optically clear, dimensionally stable and electrically stable in the GHz frequency range. Up to 500 GHz, the dielectric constant value is 2.53. Polystyrene also has excellent sound transmission properties. Therefore, polystyrene is used as a substrate in high-frequency circuits of microwave components.

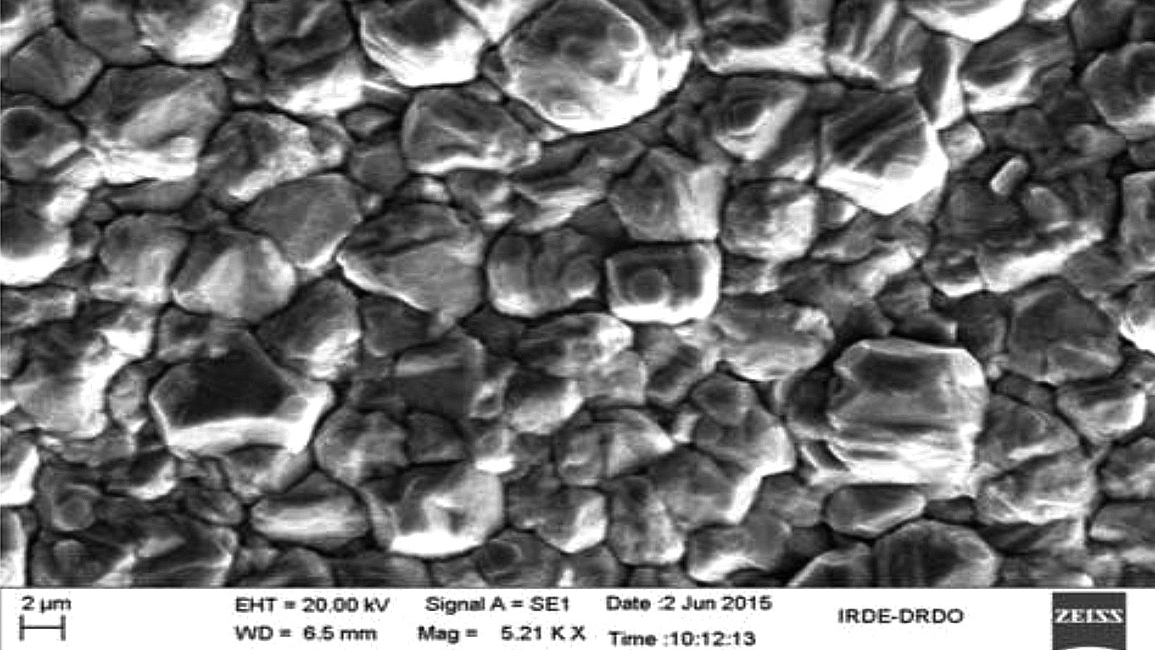

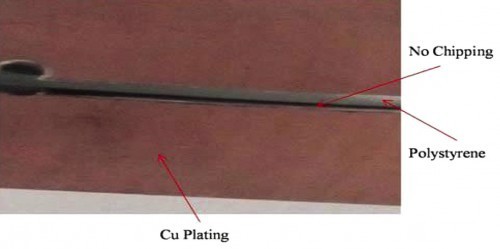

Scientists in Dehradun and Kolkata have jointly investigated the electroless copper plating of polystyrene. The electroless copper plating steps of polystyrene were similar to those of ABS. Polystyrene was treated with lye, nitric acid and tin(II) chloride in hydrochloric acid and then activated with palladium(II) chloride. The substrate was then immersed in a sulphuric acid solution for three minutes to accelerate electroless copper plating. It was found that a concentration of 9.2 mL sulfuric acid in 100 mL water worked best as an accelerator. The bath consisted of copper(II) sulphate, sodium carbonate, Rochelle salt and sodium hydroxide. Formaldehyde was used as a reducing agent.

All coatings were carried out at approximately 27 °C and at a pH value of 13.0. The samples were then electrolytically copper-plated. The optimum parameters are described in detail in the publication.

Sådhanå (2020)45:156 Indian Academy of Sciences https://doi.org/10.1007/s12046-020-01377-3

Metal Additive Manufacturing

The Swiss m4m Center for Additive Manufacturing, based in Bettlach, was launched in 2019, initiated by the Swiss Federal Laboratories for Materials Testing and Research EMPA. Swiss m4m works with highly experienced partners in the medtech industry, including Sandvik, DMG Mori and Sisma. The center focuses on the development, application and certification of an end-to-end production line for 3D-printed implants by applying validated processes, especially in the fields of traumatology, orthopaedics, dental surgery and spine.

HELIOFAB AG 7921 (Photo: MacDermidEnthone)

HELIOFAB AG 7921 (Photo: MacDermidEnthone)

The production of medical implants is a complex process with many interdisciplinary and process-accompanying steps. It is important to generate patient-specific data using imaging techniques. Once the implant geometries have been created, they are prepared using additive processes such as selective laser melting. After various post-processing procedures, often with electroplating as the final step, the implant is produced. Because a very large amount of data has to be managed and accurate mapping is essential, the software requirements are also high. The Austrian software developer CADS Additive will install solutions at m4m AM-Studio for the digital mapping of the process chain relevant to production in a so-called PTC Creo® and PTC Windchill® environment. ISO 13485 certification is being sought.

www.cads-additive.com; www.swissm4m.ch

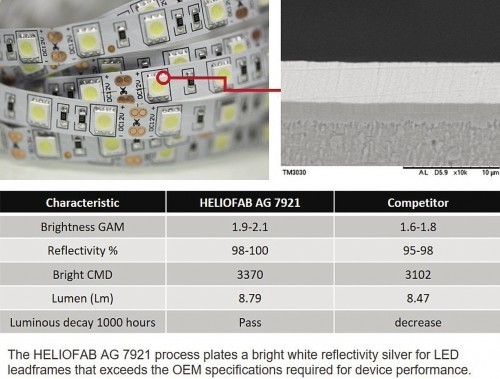

LED silver plating

MacDermid Alpha Electronic Solutions has launched a high-gloss silver plating process (selective spot plating) for punched grid-based LED packages. The spot plating surface obtained using the so-called HELIOFAB® AG 7921 process is suitable for the die attach and wire bonding production steps.

The GAM values of the silver coating are around 2.0 at a current density of 10 to 70 A.dm-2 . The silver bath gives stable coatings above the 100 A.h.L-1 standard. The silver layer fulfills all requirements regarding LED performance. According to the company, the process is already in use in industry.

http://pcb.iconnect007.com/index.php/article/125423/macdermid-alpha-releases-heliofab-ag-7921-high-brightness-silver-for-leadframe-based-led-packages/125426/?skin=pcb

Address of the author

Dr. Nagaraj N. Rao, RRR House,

RRR Labs Pvt. Ltd,

Plot 80, Sector 23,

Navi Mumbai - 400 705, India;

E-mail: