The range of applications for complex, nanostructured metals is constantly increasing. Thanks to small-scale additive manufacturing (AM), access to such 3D structures on the nanoscale is possible without the geometric constraints of two-dimensional lithography.

Droplet-Confined Electroplating

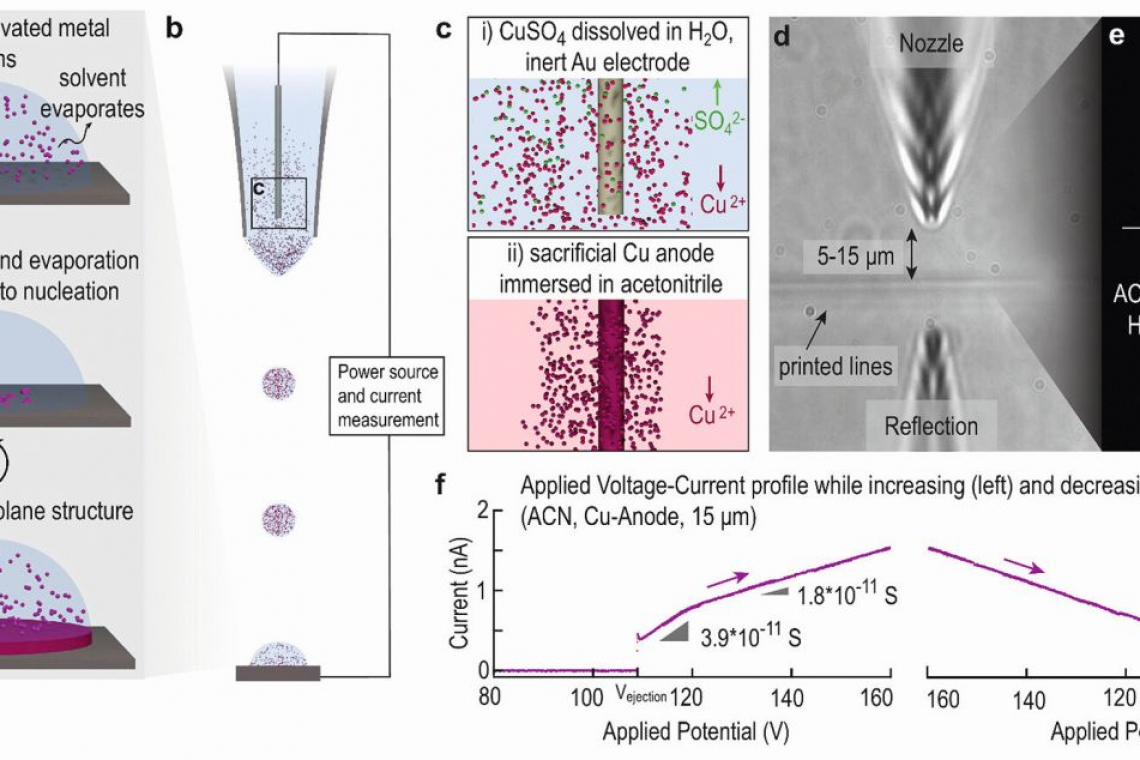

Small-scale AM techniques based on localized electrodeposition could be particularly suitable for the deposition of device-grade metals because of the high purity and dense microstructure of the deposited metals. Such electrolytically coated metals often exhibit excellent mechanical and electrical properties. Scientists at ETH Zurich have thoroughly investigated this method in the production of nano-copper wires.

The local supply of electrons and metal ions and the inclusion of the electrolyte are major challenges to be overcome. However, a major drawback of this electrodeposition is the current lack of control over the process, due to its dynamic nature and the nanoscopic size of the droplets involved. The deposition current offers itself as an obvious real-time window for deposition. The study results point to different deposition regimes and relate the current to both the morphology and volume of the deposited copper. This enables optimized electroplating strategies and the calibration of the so-called slicing algorithms required for controlled deposition of 3D structures with different solvents. With the ability to select suitable solvents, this novel technique enables the reliable deposition of functional structures with sub-micrometer resolution.

ACS Electrochem., https://doi.org/10.1021/acselectrochem.4c00085

Maintenance, repair and overhaul in India

India and the United States recently signed a €3.5 billion agreement for the purchase of 31 Predator drones from General Atomics and the establishment of a maintenance, repair and overhaul facility in India.

The aviation industry is focusing on maintenance, repair and overhaul in India (Photo: stock.adobe.com/naraichal)

The aviation industry is focusing on maintenance, repair and overhaul in India (Photo: stock.adobe.com/naraichal)

At the same time, the French company Dassault Aviation has announced the establishment of a subsidiary in India, based in Noida, Uttar Pradesh, which is exclusively responsible for the maintenance, repair and overhaul of the aircraft manufacturer's military equipment. And the Tata-owned Air India Group has also started construction of its mega maintenance, repair and overhaul facility on a 35-acre plot in Bengaluru, which will become a major hub for the maintenance operations of the Air India Group airlines. The Group is looking to modernize its fleets and expand its global operations.

The demand for such services has increased significantly, especially for modifications, cabin refurbishments, ad hoc work, painting and post-lease inspections. It is expected that with the introduction of new aircraft, regular maintenance, including refurbishments, will be required on a 2 to 3 year cycle.

Indian passenger car industry in transition

The Indian passenger car industry is changing relatively quickly. All the new products from Mahindra, starting with the Thar, XUV700 and Scorpio-N, have helped drive the technological development of the automotive industry. The Thar Roxx, the Indian carmaker's latest SUV, epitomizes this approach with advanced features such as ADAS, a panoramic sunroof and ventilated seats - all at a competitive price.

Perhaps Tata Motors' biggest success came in 2008 with the small, cheap Nano. The recently deceased former Tata CEO Ratan Tata had a desire to democratize car ownership with the Nano. Ratan Tata's foresight in turning around JLR or Jaguar and his foray into electric mobility had a lasting impact on the industry. Although the Nano has not been a commercial success in the market, it is expected to see a rebirth in one form or another.

Meanwhile, the Indian semiconductor industry is booming, with investments from well-known companies such as Foxconn, Tower Semiconductor, Kaynes Semicon, Samsung Semiconductor India Research, AMD, PSMC Taiwan, Numelo Technologies and Tokyo Electron. The automotive industry is an important consumer of products from the semiconductor industry.

On our own behalf

Dear reader, for more than twenty years I had the opportunity and the special honor to write a report from India every month. At our first meeting in the spring of 1984, Kurt Reichert, then Managing Director of the publishing house, persuaded me to become a columnist for "Galvanotechnik". Since then, I have fulfilled this task to the best of my knowledge and belief. It is with a heavy heart that I have decided to end this activity at the end of the year.

I would like to thank the publisher, the editorial team and, of course, especially you - the readers. I wish you a Merry Christmas and a successful, fruitful and eventful New Year 2025!