In electroplating, surfaces are functionalized by coatings, for example to protect them against corrosion or to make them conductive. However, functionalization is not always required on the entire surface. Various methods are used for selective electroplating. The selective electroplating of aluminium poses a particular challenge.

The reason is obvious: due to the complex pre-treatment of the light metal, there are a number of hurdles to overcome with aluminum.

Covering

The two common techniques are bonding and painting. Which method is used depends on the following parameters

- Part geometry

- Part size

- Ratio of covering to galvanized surface

- Surface cleanliness (cleanness)

- Surface roughness

- Electroplating process technology

- costs.

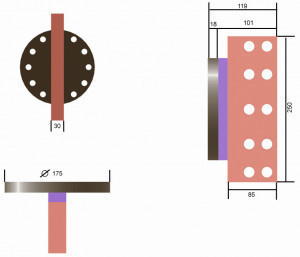

If possible, bonding is the first choice. The transition between the cover and electroplating usually has to be bonded with aluminum tape anyway. The technique is also quicker and adhesive tape is cheaper than paint. The more the geometry tends towards a spherical shape, the larger it is and the more it has to be completely immersed, the more likely it is that painting will be considered (Fig. 1).

Fig. 1: Drawing and 3D view of a component. Only the pink area is to be coated. The rest is covered

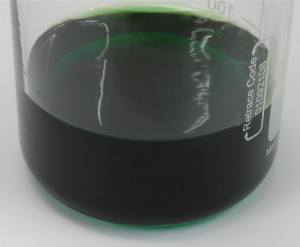

Fig. 3: Commercially available zincate stainThereare various paints and a plethora of adhesive tapes on the market for such purposes. Both must adhere to the surface in order to withstand the electroplating process (Fig. 2). After electroplating, they should be easy to remove. Even the best cover is useless if it cannot be removed afterwards.

Fig. 3: Commercially available zincate stainThereare various paints and a plethora of adhesive tapes on the market for such purposes. Both must adhere to the surface in order to withstand the electroplating process (Fig. 2). After electroplating, they should be easy to remove. Even the best cover is useless if it cannot be removed afterwards.

The adhesive strength of the cover depends on the roughness and cleanliness of the surface. In the best case, manual cleaning with a cloth and alcohol is sufficient; in the worst case, the parts must be cleaned in a cleaning system or degreased in the traditional way. Care must be taken to ensure that no chemical attack occurs on the surface. In addition, depending on the roughness and type of cover, too thorough cleaning can make it considerably more difficult to remove the cover.

The critical points are always the transitions. It must not come off here during the coating process, as chemicals can penetrate and cause various defects. For example, attack of the surfaces that are not to be coated or galvanization of the same. The chemicals can also leak out during the drying process and contaminate or even chemically attack the coating.

Choice of process

You can choose between dipping (Fig. 3) and pad processes. Which process is used depends on various factors. Part size and weight play the main role. As you do not have to immerse the workpieces in the pad coating process, the adhesive process is usually sufficient for covering. This does not have to be carried out over the entire surface, but only in the areas of the coating. This saves adhesive tape and time.

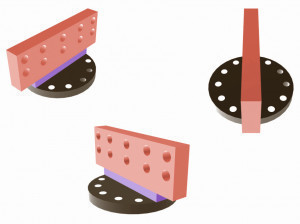

The pad process also has advantages for critical alloys, complicated geometries (Fig. 4) or simply several small areas distributed over a larger workpiece. It can happen that different coating thicknesses or even coating systems are required on one part. You can coat these separately and, if done correctly, you will not even get a dog-bone effect. In addition, you can immediately see how the surface reacts during pre-treatment and can intervene accordingly.

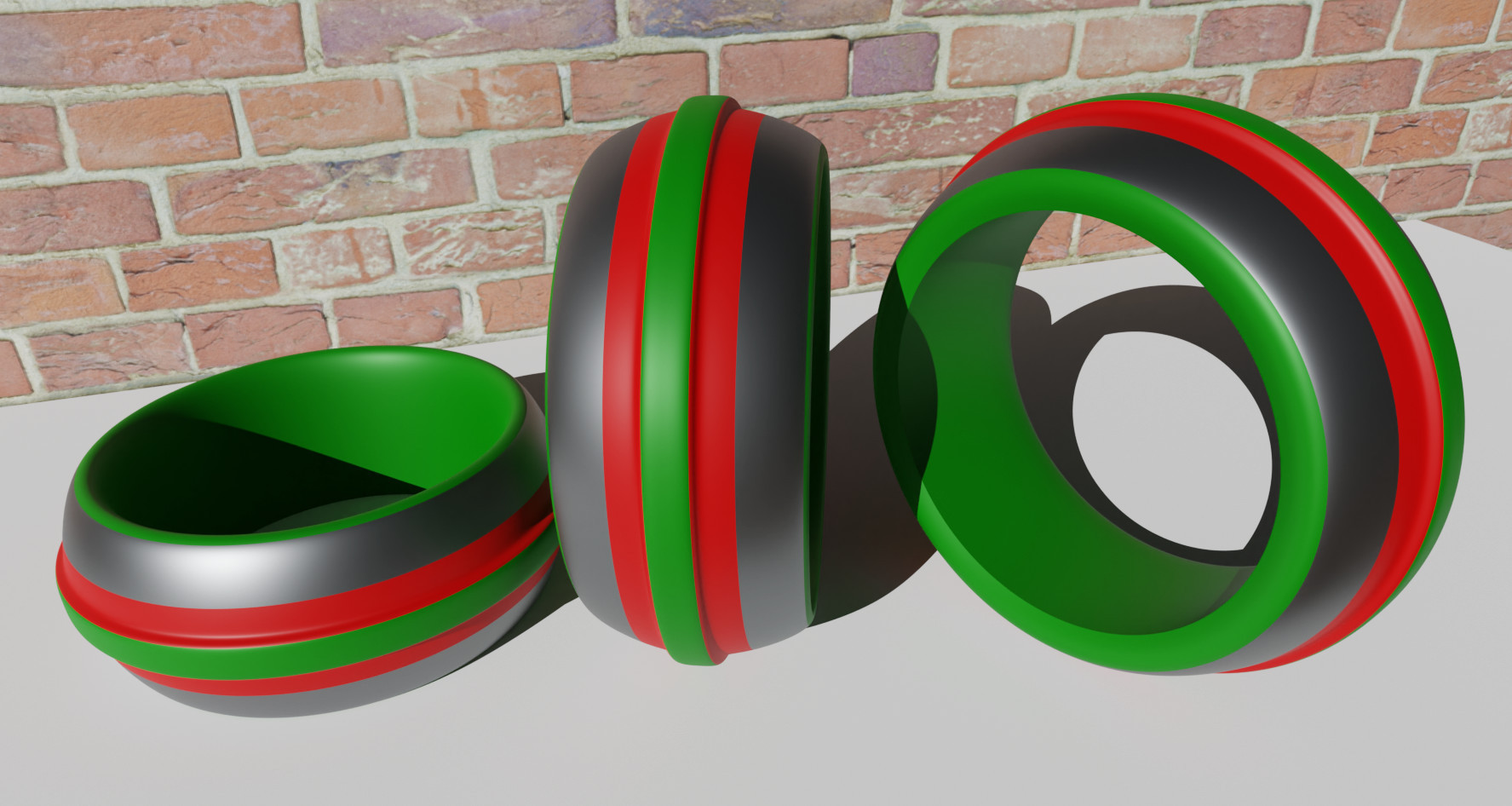

Fig. 4: 3D image of a very complex covering. Green is a masking lacquer, red an adhesive tape. The grey areas are galvanized

Fig. 4: 3D image of a very complex covering. Green is a masking lacquer, red an adhesive tape. The grey areas are galvanized

If the quantities are very high, the coating in the dipping process pays off and thus the additional effort for the covering. Process reliability is also higher here, as this process sequence is easier to define and carry out. In both cases, however, you will not achieve satisfactory results without well-trained, conscientious employees. Individual tanks are mainly worthwhile for larger parts that require a high coating thickness (> 30 µm).

Calculation

The calculation of selective coatings is more complex than classic electroplating. Among other things, this is due to numerous manual activities, the times of which must be recorded as accurately as possible. Coating times can be subject to large fluctuations. This is not only due to the human factor, but also to the individuality of the components (Fig. 5). In addition, there is the work after coating, such as removing the cover, testing the adhesive strength, mechanical cleaning by sanding, scraping and brushing.

Fig. 5: Problems caused by inadequate covering

Fig. 5: Problems caused by inadequate covering

Fig. 6: Short pipe, masked on the outside Another factor is the strongly fluctuating metal prices, different coating thicknesses and even coating systems per component and surface, as well as the coating technology itself. You should remember to calculate not only the surfaces to be coated, but also the area to be covered. The proportion of paint and adhesive tape can be very significant here.

Fig. 6: Short pipe, masked on the outside Another factor is the strongly fluctuating metal prices, different coating thicknesses and even coating systems per component and surface, as well as the coating technology itself. You should remember to calculate not only the surfaces to be coated, but also the area to be covered. The proportion of paint and adhesive tape can be very significant here.

Calculation programs contain many coating options. Up to three different areas + covering can be calculated here. Depending on the size of the parts, transportation and logistics must be considered separately. The coated workpieces are often packaged differently than when they are delivered, and internal handling also plays a role for parts weighing several hundred kilograms or more (Fig. 6).

In order to do justice to the calculation and to obtain a good post-calculation, it is necessary to inform production of the calculated resources and times. The order documents should also include the calculated ampere hours per area and a drawing with the areas marked for coverage. Sampling and initial orders must be accompanied and checked by specialist personnel. In most cases, the actual coating can be estimated well in the calculation, but preparatory and finishing work proves to be tricky, as it often happens that the assumed covering times or the removal of the same are considerably longer than expected. The overall increased expense and the unusual technology for traditional electroplating shops discourages many companies from getting involved. However, those who take the risk and specialize will have a unique selling point, at least regionally.

Images and tips and tricks in the article are taken from the online course "Electroplating aluminium". More at www.galvanotechnik-for-you.de. Click here to go directly to the course on electroplating aluminium.