Laser interference technology was developed to superimpose individual pulsed laser beams and thus transfer homogeneous periodic structures onto surfaces. With the right laser, any component and any material can be processed. The technology adds a physical surface functionalization for industrial applications to the chemical one. The first series applications have already been completed.

Where does the technology come from?

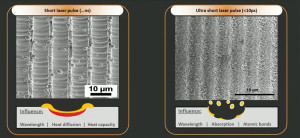

Fig. 1: Unique surface structures through laser interferenceThetechnology was first commercialized in 2020 by the spin-off SurFunction. But the story is longer. The two co-founders Mücklich and Lasagni, the inventors of the technology, began researching the targeted superposition of laser beams over 20 years ago. This went on and on until Lasagni developed the first compact optics at the Fraunhofer IWS in 2014, making it possible to transfer the laboratory experiment to industrial applications. After winning various prizes with it - including the Berthold Leibinger Prize for the best laser innovation in 2016 - SurFunction was founded as a spin-off based in Saarbrücken and Dresden. The company not only processes surfaces, but also performs corresponding material characterizations and mechanical-electrical tests.

Fig. 1: Unique surface structures through laser interferenceThetechnology was first commercialized in 2020 by the spin-off SurFunction. But the story is longer. The two co-founders Mücklich and Lasagni, the inventors of the technology, began researching the targeted superposition of laser beams over 20 years ago. This went on and on until Lasagni developed the first compact optics at the Fraunhofer IWS in 2014, making it possible to transfer the laboratory experiment to industrial applications. After winning various prizes with it - including the Berthold Leibinger Prize for the best laser innovation in 2016 - SurFunction was founded as a spin-off based in Saarbrücken and Dresden. The company not only processes surfaces, but also performs corresponding material characterizations and mechanical-electrical tests.

The SurFunction technology is called xDLIP for Extended Direct Laser Interference Patterning.

What does laser patterning look like and how does it work?

Using short light pulses from nano-, pico- or femtosecond lasers, at least two partial beams are used in a targeted manner to cause them to interfere. In the simplest case, with two partial beams, these have line structures in the order of a few micrometers up to a maximum of 15 to 20 micrometers, down to a line structure of only a few hundred nanometers, depending on the laser source. With the appropriate wavelength of the laser and the corresponding pulse energies, virtually all materials can be processed and are not limited to line patterns. With more partial beams, all periodic patterns can be realized.

Advantage of laser interference technology

Laser processing has been around for a long time and laser writing is already well established, e.g. for tools. What happens during laser writing? There is always a focusing optic and a focal point that can be worked on. This means that, in the best case, structures are shot into the material serially - there are now also other methods to parallelize this.

The periodic information is stored in the entire area of these superimposed beams by means of interference. This means that not one line or feature is shot into the surface in one shot, but hundreds to thousands of individual features. This enables fast, very surface-sensitive but also very gentle action on thin surfaces, for example. At SurFunction, the process is adapted precisely to the application in combination with materials technology expertise. Interference structuring can be achieved thermally using a nanosecond laser. The material is melted locally at the points with constructive interference on the surface, while it remains cold in between. The melt flows together there because there is a simultaneity in the process - this allows unique surface structures to be created (Fig. 1). The whole thing is a thermally induced process, i.e. there is a melt. The heat penetration zone is in the range of a few micrometers.

If it is now to be even smaller and even more precise structures are to be produced, work is carried out in the range < 10 picoseconds or femtoseconds. It is then possible to ablate the material. This means that there is no longer a remelting process, but the material is evaporated on the surface. This makes even smaller structures and other features possible.

Application in surface technology

Fig. 2: Pilot system for structuring electrical connectorsAnyperiodic structure can be applied to the material. The more partial beams, the more complex it becomes, but it remains feasible. This technology is very fast thanks to parallelization; square meters can be structured every minute. Chemical coating is then no longer necessary. The new generation of compact optics makes the process even more reliable and predestined for automation.

Fig. 2: Pilot system for structuring electrical connectorsAnyperiodic structure can be applied to the material. The more partial beams, the more complex it becomes, but it remains feasible. This technology is very fast thanks to parallelization; square meters can be structured every minute. Chemical coating is then no longer necessary. The new generation of compact optics makes the process even more reliable and predestined for automation.

Fields of application that SurFunction has also successfully addressed in industrial implementation in recent years include electrical contacts. The requirement from industry is to plug more and more individual connector pins into a connector. However, this is limited by the so-called mating forces. At the same time, very high reliability is expected and, ideally, the contact transition resistances should also be reduced. The laser interference process is capable of achieving this and has already been used in series applications. Due to the small scale and precision, the process is also extremely interesting for tribological applications - not only for lubricated friction, but also for dry friction.

Due to the interaction with visible light, the structures are also very beautiful. This opens up completely new possibilities for plagiarism protection, brand protection and optically very high-quality surfaces.

The topic of wetting is also exciting. Structures ranging from superhydrophobic to hydrophilic surfaces can be created. Additional stabilization of the surfaces may also come into focus. The topic of wetting plays a direct role in medical and hygienic applications. The size of the structures corresponds to that of bacteria. In combination with copper or silver, for example, actively germicidal surfaces can be designed and in some cases up to 15 times higher killing rates can be achieved when it comes to preventing biofilm. The biofilm reduction rate is over 80 %.

Another area of application is the solar energy sector. By structuring film with our technology, the refraction of light can be adjusted to increase absorption by up to 35%. This opens up new, sustainable possibilities for making solar cells more efficient.

Figure 2 shows the first pilot system on which electrical connectors are structured. The individual pins are wound onto strip material and are structured over their entire surface in the functional area using xDLIP optics (black boxes in the foreground and background). This is done during the running process and creates a very stable interference volume. Depths of up to 7 mm can be achieved. This means that the application is very fast and not limited in any way. Large industrial applications have been developed for three years with a proof of concept.

Strategic partners include the Material Engineering Center Saarland (MECS) and the Technical University of Dresden, which is a leader in laser and optics expertise in particular. The automation partner, particularly in the area of connectors, is Noxon Automation, which can implement the entire process in production.

Several projects were carried out with Matthias Maurer (Fig. 3) on the ISS space station. On the one hand, the topic was biofilm prevention, as it is difficult to ventilate in space. This means that you have to think about how to actively prevent biofilm formation beforehand. The second is the topic of antimicrobial surfaces, particularly in the "Touching Surfaces" experiment for active germ killing, which is also relevant for terrestrial problems. This experiment was chosen by Matthias Maurer as his personal experiment on the ISS. Experiments are also to be carried out at the South Pole in the near future.

The so-called "space spoon" is the spoon with which Matthias Maurer ate his star cuisine from Saarland on the ISS. The spoon he ate with has structures on it that were created using laser interference technology. This makes it possible to see what has happened on the surface under a scanning electron microscope.

The article is based on a presentation at Surface Technology in Stuttgart in June 2022. SurFunctions antimicrobial surfaces were also presented on the ISS during Dr. Frank Mücklich's keynote speech on the opening day of the ZVO Surface Days in Leipzig.