Corrosion starts on the surface of components and eats further and further into the material until the components lose their suitability for use. They are often too valuable to be scrapped. Thanks to customized high-performance coatings, their serviceability can be restored and the service life of the systems significantly extended. This expertise is also increasingly being used by the original manufacturers of machines and systems.

The tasks in the area of wear and corrosion of machine parts are so diverse that there are rarely off-the-shelf solutions," says Martin Bührer, owner of Bührer AG in Otelfingen (Switzerland). Thanks to modern CAD systems, the mechanical properties of mechanical components can now be calculated relatively easily and with a high degree of reliability. However, the situation is different with surfaces: although the surface layer only accounts for a few percent by weight, it is decisive for the service life. Even comparatively minor variations in environmental conditions can have a significant impact on life expectancy. This is why he focuses on consultation and problem-solving when dealing with customer inquiries: what are the operating conditions, what wear patterns are evident in the components and what special features may need to be taken into account. The next step is to clarify which coating variants - metallic, ceramic or multilayer - are most likely to be suitable and which process is best for applying them. If necessary, tests would also be carried out. To apply the coatings, Bührer AG uses high-performance thermal spray processes such as atmospheric plasma spraying (APS), high velocity oxy-fuel spraying (HVOF), arc spraying and flame spraying.

Complete service from a single source

"It is also important that we offer the customer a complete package of upstream and downstream machining," adds Martin Bührer. This means that the customer receives the entire service package from a single source and under one responsibility. It is also faster and cheaper because interfaces, transport costs and delays along the logistics chain are eliminated. This is why he is continuously investing in the expansion of his machinery. The company has CNC-controlled systems for milling and turning as well as a CNC-controlled internal and external cylindrical grinding machine for diameters of up to 300 mm. This is supplemented by a conventional lathe for diameters of up to 500 mm and component lengths of up to 3,000 mm.

Coating takes place at two stations, including a modern system from OSU-Hessler. Both are equipped with robots that can also be used to coat complex geometries in three dimensions. He is also prepared to manufacture or procure additional equipment for special tasks, such as a station for automated brushing. Thanks to this flexibility, he can also take on unconventional tasks.

Wide range of coating materials

"In contrast to the usual hardening processes, the workpiece does not have to be heated to a high temperature for spraying, so that neither structural changes nor distortion occur," he reveals. The material to be applied is liquefied by heat and accelerated towards the workpiece in the form of finely atomized droplets. When they hit the surface, the droplets conform to the shape of the component and penetrate even the smallest recesses. When they solidify, a firmly adhering bond is created, which is based partly on welding and partly on interlocking. It can be easily machined using mechanical processes such as milling, turning, drilling or grinding. As there is no chemical reaction, a wide variety of coating materials can be used without having to worry about chemical compatibility. Depending on the technology and material, high coating thicknesses of up to 10 mm are also possible in some cases. Metals are usually processed in the form of wire, which is liquefied by an electric arc and then atomized by a sharp gas jet and accelerated towards the workpiece. For ceramic materials, fine powders are used which are melted in the plasma torch at high temperatures and then impinge on the workpiece. In terms of coating materials, his company has the entire range from soft bearing metals to corrosion-resistant industrial metals such as stainless steel, aluminum, zinc, nickel and chrome to ultra-hard oxide ceramics with hardnesses of up to 1500 HV.

Example: godets for the textile industry

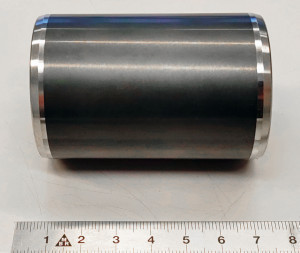

"The order from a leading global manufacturer of plastic fibers to coat these godets is an expression of the customer's trust in our expertise," says Bührer happily. Galettes are large, hollow cylinders that are used in the production of plastic fibers. They are used to deflect the still soft polyester thread, which comes down from spinnerets from above, in several stages and temper it in such a way that high-strength yarn is ultimately produced. A total of seven of these godets must run so precisely synchronized and also completely impact-free that the still solidifying raw yarn is not jerkily overstretched and thus damaged.

It is also crucial that the coating does not stick to the sticky thread material and has sufficient grip to ensure that the thread can be conveyed safely. This coating consists of two layers: first, a 0.05 mm thick metallic adhesive primer made of Ni-Cr is applied to the carefully cleaned surface using the APS process. A 0.1 mm thick layer of a mixture of aluminum and titanium oxide is then sprayed onto this base using the same process.

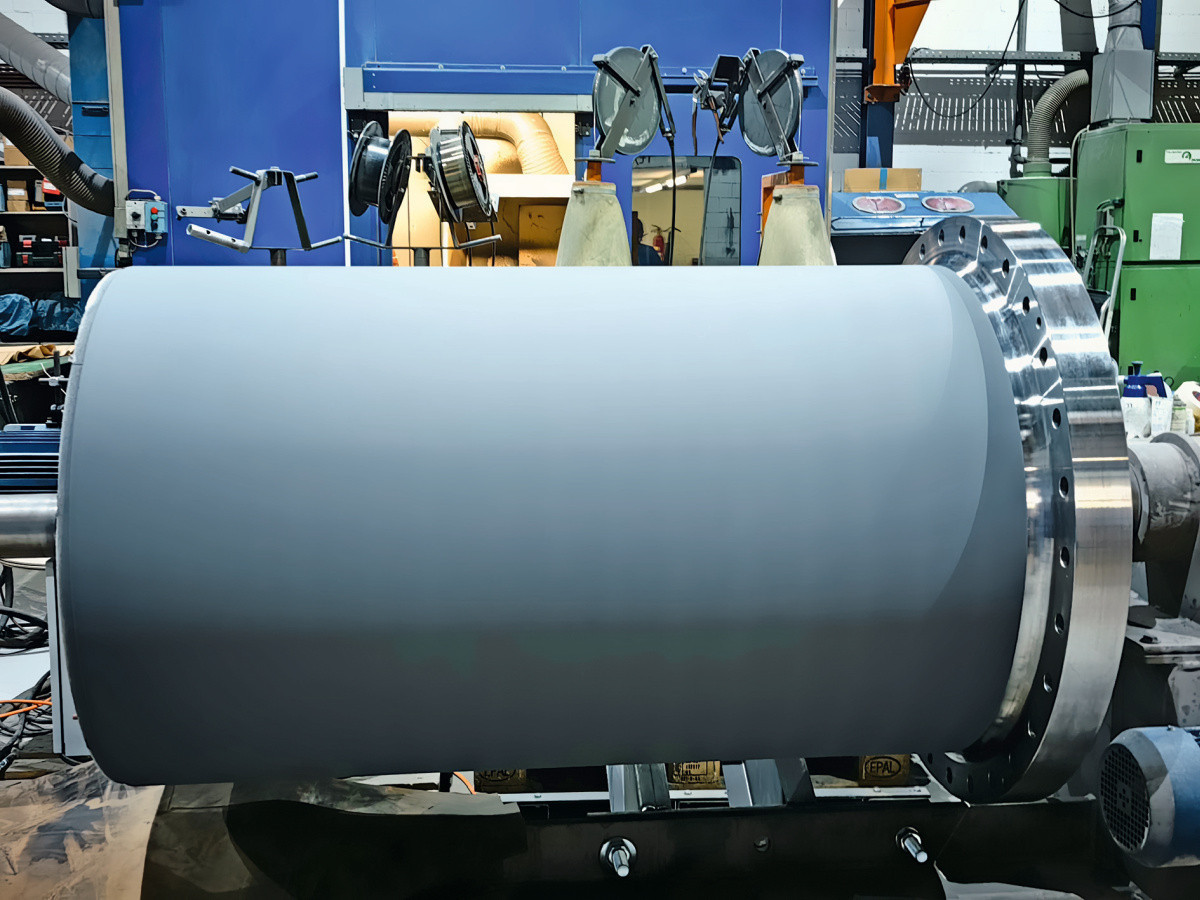

A finished coated godet at a station where it is first automatically brushed off and then inspected

A finished coated godet at a station where it is first automatically brushed off and then inspected

Extreme care

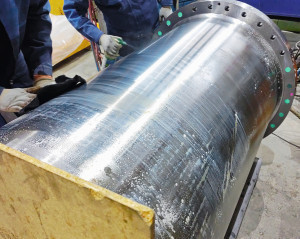

"But that's just the short version. In reality, the processes are much more complex," explains Bührer. Extensive preparation is required before the primer is applied. This includes pre-plastering, cleaning, pre-heating, masking and finally blasting. The application of the primer coat then requires three passes and the subsequent coating with ceramic even requires ten passes. During priming, a careful visual and manual check is carried out after both the first and the third coat for spraying defects such as larger droplets of enamel that have baked in. It is necessary to apply the ceramic in ten individual layers because cracks could occur when thicker layers are applied. After the last pass, the overall diameter must be checked, taking the component temperature into account. This is necessary because the diameter of the synchronously driven godets in the line must match exactly in order to avoid irregularities in the thread tension during operation.

Before the cover is fitted, the finished godet is carefully wrapped and secured on a pallet. In the background, another godet is already being prepared for treatment

Before the cover is fitted, the finished godet is carefully wrapped and secured on a pallet. In the background, another godet is already being prepared for treatment

Finally, the godet is taken to a specially developed and manufactured test stand for final inspection. There it is first cleaned of any loose grains using an automatic brushing device and then scanned extremely thoroughly by hand. Even the smallest irregularities are carefully removed by hand. After a final brushing pass, the galette is then carefully packaged and prepared for dispatch in a sturdy transport box.

Further examples

"The galettes are just one of many examples of the care we take when fulfilling customer orders," explains Martin Bührer. He attaches particular importance to flexibility when responding to customer requests and takes on simple jobs such as blasting corroded motor housings as well as rebuilding ceramic wear layers for hydraulic motors, including high-precision machining to the desired final dimensions. For round parts, it is possible to machine such coatings down to a residual roughness of just Ra = 0.2 µm. For more complex geometries, he can rely on a network of proven partners. The most important thing for him is that the customer receives comprehensive advice and an optimum solution for their specific task.