With their innovations, such as new types of surfaces for solar cells, electroplating companies are making a major contribution to climate protection. However, as energy-intensive companies, they must also reduce their own greenhouse gas emissions. What is the right strategy for this? Which measures make sense? And what are the subsidies available for?

One question arises first: why should the company make an effort to protect the climate? There are many reasons for this. In addition to the most obvious, namely the need for more climate protection in general and the growing awareness of this throughout society, there are numerous other reasons for companies: most measures help to increase price and supply security. And because more and more companies are paying attention to thecarbon footprintof their products or services when purchasing, climate protection measures also help the company's competitiveness. In addition, there are legal and regulatory requirements, such as the BEHG (Fuel Emissions Trading Act) with the BECV (BEHG Carbon Leakage Regulation) or the EU taxonomy, which are constantly making the emission of greenhouse gases less attractive or more expensive. Numerous subsidies are currently available to make it easier for companies to make the switch. It therefore often makes sense to start now, before programs are exhausted or closed again. One of the most important for industry is the EEW (Federal Subsidy for Energy and Resource Efficiency in Industry). It is widely known that numerous measures are funded under this program. What many people do not yet know: Transformation concepts are also funded as part of the EEW. The most important requirement for such a concept is a ten-year action plan to reduce Scope 1 and Scope 2 emissions by at least 40%. Companies can receive up to 80,000 euros for drawing up the concept.

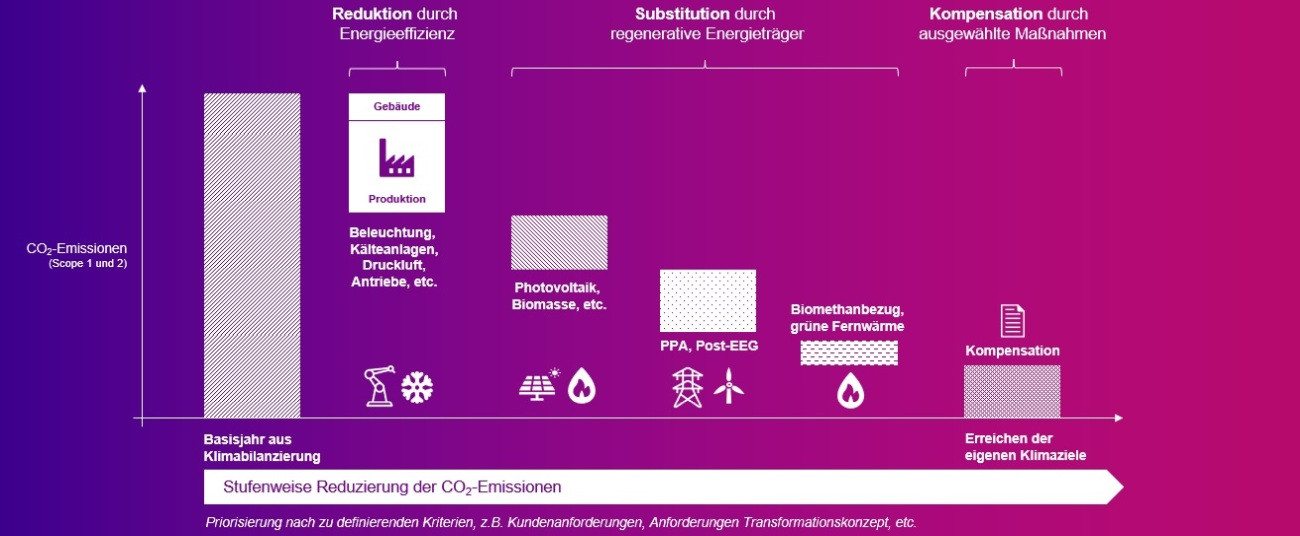

CO2 emissions are gradually reduced by means of reduction, substitution and compensation

CO2 emissions are gradually reduced by means of reduction, substitution and compensation

In addition to the major federal subsidies, there are also many at EU and federal state level as well as from private sponsors, e.g. development associations. However, the decision as to which funding offer to choose should be made carefully. This is because there are always several funding offers for one measure, some can be combined, while others are mutually exclusive.

Individual paths to the goal

The ideal decarbonization path for electroplating companies, i.e. the process for reducingCO2 or greenhouse gas emissions, cannot be described in general terms. This is because every company starts with its own individual circumstances. However, there are some fixed points that are generally recommended.

A sensible first step is a workshop with all relevant people. This definitely includes the management, the technical manager, the energy manager and the department heads. During this workshop, they can all contribute their ideas and expertise and set priorities together. This makes it easier to define sensible measures later on, which will also find broader support within the company. The participants should also define the reporting and set initial rough targets. The methodological and content-related support of an independent external consultant is helpful here.

Data forms the basis

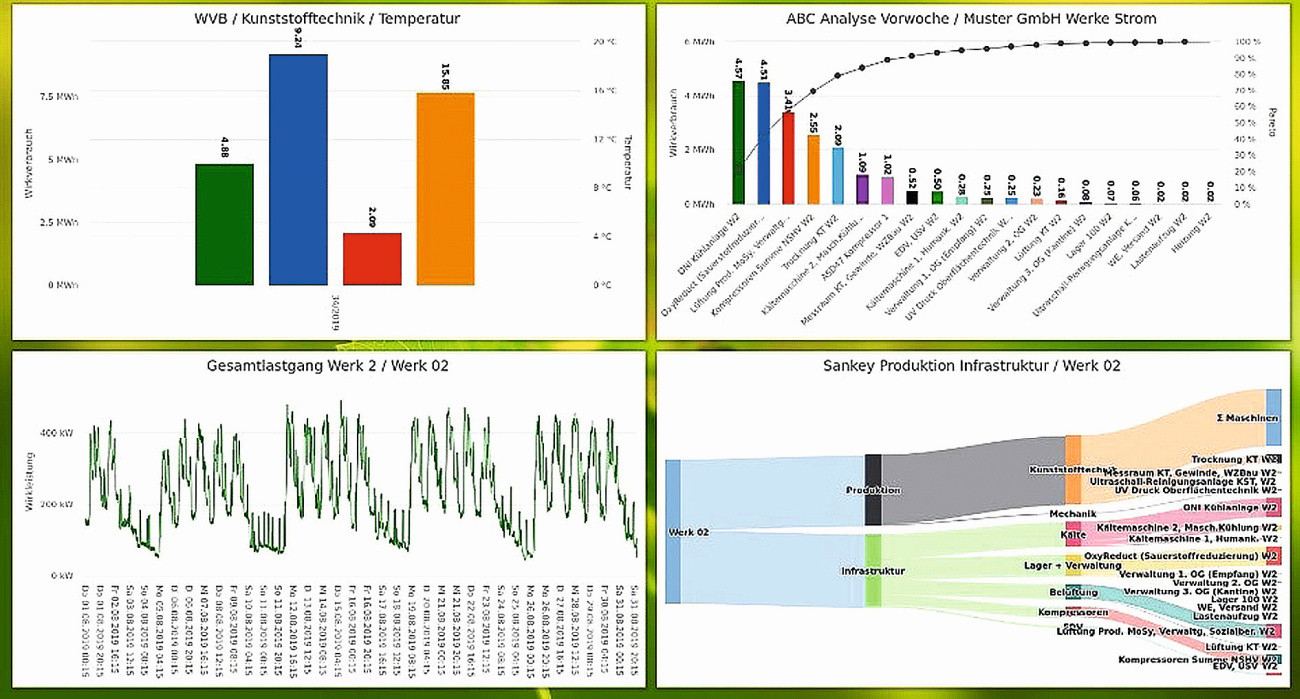

In order to determine the path to the goal, you need to know the starting point, i.e. the current situation. Only those who know when and where how much energy is consumed can identify optimization potential, prioritize measures, readjust if necessary and measure success.

Electricity consumption is a decisive factor for electroplating companies. Companies with ISO 50001 certification usually already have a sufficient database and a well-developed energy monitoring system with which they can identify their largest consumers (SEUs, Significant Energy Use) and derive KPIs (Key Performance Indicators).

If there is not yet sufficient measurement technology available to record data at the required level of detail, the installation of an energy monitoring system is recommended. Ideally, this should be integrated flexibly and manufacturer-neutrally into the existing hardware and software. Existing measurement technology can then continue to be used and data from other company systems can also flow into the system. The software translates the measured values and data into clear diagrams and reports. This makes the largest consumers, standstill losses and load peaks as well as correlations between consumption and external influences immediately apparent, for example.

Define meaningful key figures

However, much consumption data is not very meaningful on its own, as it depends on other aspects, e.g. production volume or temperature. It is therefore crucial to define meaningful key figures. For electroplating companies, this can be the energy input per galvanized square metre. Looking at the energy costs in relation to the production costs or the energy consumption of a process in relation to the total energy consumption or the number of units can also provide interesting insights.

It is important to think about which key figures are relevant for your own company before installing measuring devices. This can then be taken into account in the measurement concept so that the necessary values are available later. Data from other company systems (e.g. MDE/BDE, ERP) is often also required for this. If these can be automatically integrated into the energy management system via interfaces, the current key figures are automatically available at all times.

Carbon footprint shows footprint

In the next step, the carbon footprint is created as a description of the current status. Recognized accounting systems, e.g. the Greenhouse Gas Protocol, provide the corresponding framework. Accordingly, all greenhouse gas emissions from the various areas of the company must be listed and, if necessary, converted intoCO2 equivalents. This provides the company's currentCO2 footprint(corporate carbon footprint). This can also be used to calculate theCO2 footprintof individual products (product carbon footprint), which large companies in particular are increasingly demanding from their suppliers.

An energy management system shows the energy flows and load profiles, the largest consumers and much more at a glance

An energy management system shows the energy flows and load profiles, the largest consumers and much more at a glance

The easiest emissions to determine are those caused by the company on site (Scope 1). This is largely covered by the data from the energy management system. Scope 2 comprises the indirect emissions associated with the grid, which are primarily caused by external energy generation or supply. They can usually be obtained from the energy supplier. Scope 3 is much more complex and includes all emissions caused along the value chain, from the raw materials to the use and disposal of the product. They are not only more difficult to record, but also more difficult to influence. For this reason, they are often left out of the equation. However, more and more companies, especially larger ones, are also determining their Scope 3 emissions and are therefore asking their suppliers about theircarbon footprint or specifyingCO2 limits.

Setting climate targets

The carbon footprint is the starting point for setting targets. It is advisable not only to specify by when the company should be climate-neutral or climate-positive. Rather, it is also necessary to set milestones, e.g. a 50% reduction inCO2 emissions by 2030. This makes it easier to check whether the direction is right or whether adjustments need to be made.

A roadmap with suitable measures should then be drawn up in order to achieve the specified targets. It makes sense to proceed in three major steps: You start with reduction, followed by substitution and finally compensation.

Reduction

The first step is to reduce emissions - i.e. primarily energy consumption. In electroplating companies, the greatest savings potential is usually found in production. Technical measures are often necessary to exploit this potential, such as retrofitting machines or using more efficient technology. However, technologies and/or investments are not always necessary. MVV Enamic GmbH from Mannheim has already carried out many projects in which process or behavioral changes in the right place have resulted in high savings.

It is also worth thinking further: emissions can be reduced in countless areas, be it in company buildings with air conditioning, lighting, etc., in the vehicle fleet or in business travel by switching from car or plane to train. Raising employee awareness can also have a major impact. Evaluations from energy management often provide a good basis for this.

Substitution

The more reduction measures a company has implemented, the more difficult it becomes to reduce energy use further. The second step is therefore to cover the remaining energy requirements with as little carbon as possible. The simplest option is to purchase green electricity from renewable energy plants (RE plants).

It can also be worthwhile to generate renewable energy yourself on site, for example with your own PV or biomass system. An alternative to purchasing and operating such a system is a PPA (Power Purchase Agreement). This long-term electricity supply contract between an electricity producer (plant operator) and an electricity consumer (company) stipulates the amount of electricity the operator will supply to the company from a renewable energy plant and under what conditions. In this way, the company secures green electricity and receives long-term price and supply security without having to make its own investments and without having to worry about the operation and maintenance of the plant.

In the area of heat, theCO2 balance can be improved by means of a fuel switch, i.e. switching to more climate-friendly primary energy sources such as biomass, own residual materials, hydrogen, biomethane or similar. The use of a heat pump to utilize waste heat or to combine it with cooling processes also offers an efficient way to decarbonize if it is operated with renewable electricity. In the context of the current discussions on security of supply, an electrode boiler for generating warm/hot water or steam through clever sector coupling can be a sensible alternative. The economic viability of such substitution measures in the area of heat supply has increased even further due to the introduction ofCO2 pricing for fossil fuels in 2021. There are also some significant subsidies available here.

INFO

Scopes in the climate balance sheet

Scope 1

includes all direct greenhouse gas emissions resulting from a company's own business activities, i.e. from the consumption of primary energy sources and process emissions generated during the production process.

Scope 2

comprises the indirect greenhouse gas emissions resulting from the generation of energy procured by a company that is grid-bound.

Scope 3

includes all other indirect greenhouse gas emissions resulting from upstream and downstream corporate activities.

Compensation

Even with the help of all technically and economically feasible measures, it is generally not possible to reduceCO2 emissions to zero. In order to become carbon neutral, companies can offset these emissions with certificates. Although these offsetting measures may not be included in the carbon footprint, they can be used in communications to demonstrate the company's commitment to climate protection to customers, partners, other stakeholders and the public.

An offset certificate certifies that a certain amount ofCO2 emissions has been saved through a climate protection project. The company that acquires such a certificate can determine the framework conditions and the type of project. Specialized service providers select a specific offsetting project according to these specifications as well as price and availability and take care of the procurement and validation of the certificates. The validation ensures that theCO2 saved is transferred to the buyer and is no longer for sale. The buyer receives a delivery certificate with all relevant information on the neutralization ofCO2 emissions.

Galvanotechnik author Jan Mehlberg gave a presentation on the topic at the Ulm Talks in May 2022.