Tungsten enables the functionalization of surfaces in a variety of ways, for example through corrosion and radiation protection and thermal conductivity. A solid solution alloy in powder form has now been developed that can be used in 3D printing or coating processes.

Tungsten alloys (WNiFe/WNiCu) are used in aluminum die casting due to their corrosion resistance to molten metal and their high thermal conductivity. However, the heavy metal with a density comparable to gold has also become indispensable in tool manufacturing and for shielding alpha and gamma radiation. However, at around 3,400 °C, tungsten has the highest melting point of all chemical elements and is therefore very difficult to machine due to its Mohs hardness of 7.5. As a result, components with more complex shapes, such as curves or conical bores, often have to be made from hot-work tool steel, which is easier to shape. In order to enable the use of tungsten for these more demanding geometries and thus increase the efficiency and durability of the components, Bayerische Metallwerke GmbH from Dachau has developed a new manufacturing process for the tungsten alloys WNiFe and WNiCu and had it patented at the beginning of 2021. This is characterized by the fact that the multiphase solid solution alloy is obtained in a powder form that is suitable as a starting material for 3D printing and coating processes.

"Due to its resistance to corrosion and erosion of molten metals as well as its excellent thermal conductivity, tungsten is the material of choice for aluminum casting," says Nabil Gdoura, research and development engineer at Bayerische Metallwerke GmbH. "The very high density of 19.25 g/cm3 in its pure form also makes it a good alternative to lead, which is harmful to health and is still used for radiation shielding in medicine, for example." The casting molds used in aluminum processing, also known as permanent molds, often require long but very thin and sometimes conically shaped cooling channels with a diameter of less than 1 mm in order to ensure that heat is dissipated as evenly and quickly as possible. Otherwise, the material quality of the end product can be negatively affected by cracking, for example. However, it is impossible to model such precise and partially curved shapes from the hard heavy metal, whose extremely high melting point is between 3,387 and 3,422 °C, using conventional machining or forming techniques. For this reason, hot-work tool steel, which can be shaped into almost any desired form using 3D printing techniques, has so far had to be used for these complex components for the aforementioned applications.

New tungsten alloy in powder form suitable for 3D printing

After completing the two-year development phase, Bayerische Metallwerke applied for a patent for its new manufacturing process for a tungsten alloy product and its further use at the beginning of 2020, which was finally granted in January of the following year. "The special feature of our tungsten-nickel-iron alloy is that we obtain it in the form of a pre-alloyed powder," explains Dr. Hany Gobran, Research and Development Manager at Bayerische Metallwerke and inventor of the manufacturing technology. "This is suitable as a starting product for 3D printing and coating processes." In the absence of an alternative, only a mixed powder has been used to date to make tungsten usable for components with complex geometries. However, the biggest disadvantage of such mixtures is the different melting points of tungsten (around 3,400 °C) and of nickel and iron, which both change their aggregate state at around 1,500 °C. As a result, a large proportion of the two added materials evaporate uncontrollably during the melting process. This is because the boiling point of nickel and iron is already around 2,700 °C and 3,000 °C respectively. Thanks to the pre-alloying in the process developed by Gobran, however, all three elements are combined in each individual powder particle as a multiphase material so that their composition and distribution in the end product can be precisely controlled and no loss of the binder metals has to be accepted.

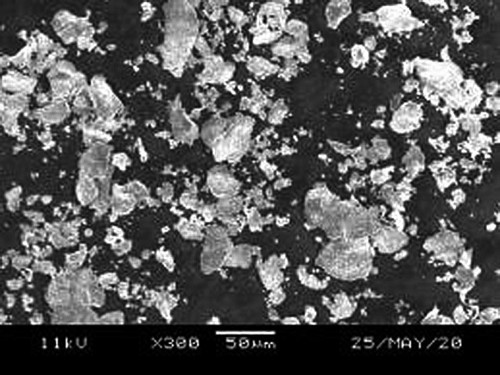

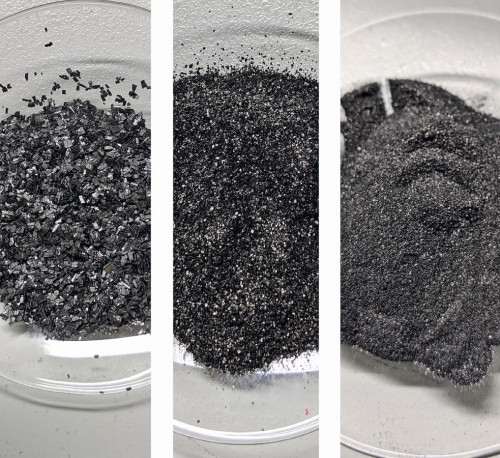

During the comminution process as part of the manufacturing process, the flow behavior and grain size of the powder can be determined between 10 and 200 µm. In this way, the alloy is individually prepared for the desired type of further processing

During the comminution process as part of the manufacturing process, the flow behavior and grain size of the powder can be determined between 10 and 200 µm. In this way, the alloy is individually prepared for the desired type of further processing

The new alloy can be produced with 80 to 98.5 wt.% tungsten, 0.1 to 15 wt.% nickel and 0.1 to 10 wt.% iron and/or copper in accordance with the current standardized variants. This achieves a density of the end product of 17 to 18.8 g/cm3, which is desirable for applications in the aluminum industry, tool manufacturing and for alpha and gamma radiation shielding. "The higher the proportion of tungsten in the end product, the more resistant it is to molten aluminum and the better its thermal conductivity," explains Gobran. "If, on the other hand, good ductility and mechanical machinability play a greater role, the proportion of tungsten in the alloy can also be reduced accordingly. The composition can therefore always be adapted to the specific application and the respective shape complexity." During the comminution process as part of the manufacturing process, the flow behavior and the grain size of the powder can also be determined between 10 and 200 µm. In this way, the alloy is individually prepared for the desired type of further processing - such as plasma coating processes or additive manufacturing.

New manufacturing process enables upcycling of materials

If, for example, the hot-work tool steel previously used for thin and conically shaped cooling channels in cast aluminum molds is replaced by the tungsten alloy developed by Gobran, the application not only benefits from the corrosion and erosion resistance of the heavy metal. Compared to steel, tungsten also has the advantage of much higher thermal conductivity, meaning that wear on the dies can be massively reduced. Due to its higher density, the alloy product is also an alternative to toxic lead, which is not only used for radiation shielding but also as a stabilizer - for example in the tool industry. "Another special feature of our alloy is that we can produce the powder from offcuts or chips," adds Gdoura. "This is a major step forward from both an economic and an environmental perspective, as it allows us to recycle and upcycle waste products from conventional processes."