In laser metal deposition, metal layers are welded onto workpieces or entire components are additively manufactured layer by layer. The Fraunhofer IPT has now combined the process with wire as a coating material with the so-called optical coherence tomography process. In this way, the process is set to become a fully-fledged 3D printing process in the future.

Adjustment of a component in an inert gas cell of the so-called ProLMD system. The ProLMD project was implemented by the Karlsruhe Institute of Technology (KIT) and the Fraunhofer Institute for Laser Technology (ILT), with KUKA Robotics as project leader. In this KUKA system in Würselen, it was possible to prove that robots can additively manufacture entire components using LMD. Process stability and control are of great importance in laser metal deposition (LMD): ideally, the reaction to faults and deviations must be immediate and without delay in order to prevent process interruptions. This calls for machine-integrated monitoring systems that can check the processes on the spot and initiate corrections. The Fraunhofer Institute for Production Technology IPT in Aachen, together with partners from industry and research, has integrated the imaging method of optical coherence tomography (OCT) into a coaxial process for laser deposition welding of wire. OCT can not only record the welding process, but also monitor the quality during the process and thus reduce rejects. The LMD-w is therefore set to be used as a fully-fledged 3D printing process in the future.

Adjustment of a component in an inert gas cell of the so-called ProLMD system. The ProLMD project was implemented by the Karlsruhe Institute of Technology (KIT) and the Fraunhofer Institute for Laser Technology (ILT), with KUKA Robotics as project leader. In this KUKA system in Würselen, it was possible to prove that robots can additively manufacture entire components using LMD. Process stability and control are of great importance in laser metal deposition (LMD): ideally, the reaction to faults and deviations must be immediate and without delay in order to prevent process interruptions. This calls for machine-integrated monitoring systems that can check the processes on the spot and initiate corrections. The Fraunhofer Institute for Production Technology IPT in Aachen, together with partners from industry and research, has integrated the imaging method of optical coherence tomography (OCT) into a coaxial process for laser deposition welding of wire. OCT can not only record the welding process, but also monitor the quality during the process and thus reduce rejects. The LMD-w is therefore set to be used as a fully-fledged 3D printing process in the future.

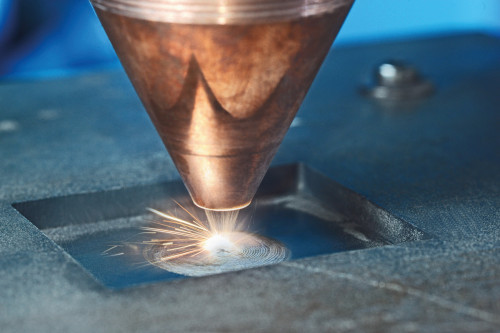

Wire-based laser metal deposition (LMD-w for short) is an additive manufacturing process in which a metal wire is welded onto a workpiece as a filler material using a laser in weld beads. Several of these weld beads next to each other form a layer, several layers on top of each other form a component. As LMD-w only applies material where it is needed, it is a resource-saving process. However, the complex process development and low process stability have so far prevented a broader industrial application that goes beyond special repair processes or the application of wear protection layers.

In the research project "TopCladd - Adaptive Laser Cladding for Precise Metal Coating Based on Inline Topography Characterization", the Aachen research partners have equipped a coaxial LMD-w-.0 system with an OCT system for the first time in order to stabilize and actively control the laser process. OCT, which has its origins in ophthalmology, is a measurement method for the non-contact and high-resolution display of tomographic cross-sectional images based on short-coherent interferometry. In combination with a high measuring frequency, OCT can be used to check and improve the surface quality of the build-up weld directly in the process.

Laser cladding plus OCT - the path to process stability

The quality of laser cladding depends primarily on the surface of the weld seam: the more wavy it is, the lower the component quality. To make the laser cladding process more stable and produce a high-quality weld seam, the process steps must be recorded individually. Poor-quality weld seams can then be subsequently repaired and the welding process adapted for future production. OCT is able to inspect the surface of the weld seam in the phase transition from solid to liquid and thus determine the shape of the final weld bead geometry. Based on the data obtained, the laser process can be adjusted in the adjacent or overlying weld bead if necessary.

In order to utilize the advantages of OCT for the laser welding process, Fraunhofer researchers integrated the OCT system coaxially into the processing head of the laser. The laser for processing and the OCT system use the same optics, but do not interfere due to their different wavelengths. The coaxiality of the processing and measuring light is ensured by the use of a so-called axicon, a cone-shaped lens and a number of prism-shaped optics. This optical design enables the measuring laser to scan the weld seam in a circle around the central metal wire. This enables multidirectional measurement, regardless of the direction of movement of the welding head. In this way, the entire workpiece can be measured without the wire blocking the measuring light.

With OCT for active process control

Component reinforcement with laser deposition welding using the Laval method. This increases the load-bearing capacity of steel and aluminum sheetsTheintegration of OCT into the laser cladding process makes it possible to precisely map the surface structure of the entire fusion track. Using the process data collected in the project, the Aachen researchers are developing a process model for data-supported process adaptation and control. This will make the laser processes more robust and open up a variety of new fields of application. "With OCT, we will not only be able to apply one or two layers on top of each other during laser metal deposition in the future, but any number of layers. In this way, LMD-w will be upgraded to a fully-fledged and sustainable additive manufacturing process," says Robin Day, head of the "Energetic Beam Processes" department at the Fraunhofer IPT.

Component reinforcement with laser deposition welding using the Laval method. This increases the load-bearing capacity of steel and aluminum sheetsTheintegration of OCT into the laser cladding process makes it possible to precisely map the surface structure of the entire fusion track. Using the process data collected in the project, the Aachen researchers are developing a process model for data-supported process adaptation and control. This will make the laser processes more robust and open up a variety of new fields of application. "With OCT, we will not only be able to apply one or two layers on top of each other during laser metal deposition in the future, but any number of layers. In this way, LMD-w will be upgraded to a fully-fledged and sustainable additive manufacturing process," says Robin Day, head of the "Energetic Beam Processes" department at the Fraunhofer IPT.

The "TopCladd - Adaptive Laser Cladding for Precise Metal Coating Based on Inline Topography Characterization" project was funded for four years by the German Federal Ministry of Education and Research (BMBF) as part of the "M-ERA.Net - flexible and needs-based transnational funding in the field of materials research" funding programme. In addition to the Fraunhofer IPT, five other companies, whose expertise was required for the realization of the development, were project partners, including Quada V+F Laserschweißdraht GmbH from Hemer.