Protective coatings can extend the service life of tool surfaces. With a new system, the Fraunhofer IPT can now conduct research into coating solutions for all types of forming tools and glass types.

Optical components with complex geometries such as aspheres, lens arrays or free-form optics can be manufactured efficiently and cost-effectively using glass forming. However, the constant heating, forming and cooling means that the forming tools are subject to heavy wear after just a few applications.

Protective coatings can extend the service life of the tool surfaces. The Fraunhofer Institute for Production Technology IPT in Aachen has now added a system for diamond-like carbon (DLC) coating to its machine park. This makes the Aachen-based institute the only facility in Europe that can now offer research into coating solutions for all types of forming tools and glass types.

Glass forming with tools heated to 800 degrees

Production of precious metal and nitride hard coatings developed at the Fraunhofer IPT as protective coatings for various glass forming tools The glass forming tools are heated to up to 800 °C in each pressing cycle, press the equally hot glass blank and then cool down again. The result of this enormous thermochemical stress is rapid tool failure, for example due to glass adhesion. Special protective coatings can be applied to the tool surfaces to extend the service life of the tool. Different types of glass require different tool coatings

Production of precious metal and nitride hard coatings developed at the Fraunhofer IPT as protective coatings for various glass forming tools The glass forming tools are heated to up to 800 °C in each pressing cycle, press the equally hot glass blank and then cool down again. The result of this enormous thermochemical stress is rapid tool failure, for example due to glass adhesion. Special protective coatings can be applied to the tool surfaces to extend the service life of the tool. Different types of glass require different tool coatings

Over the past few years, the Fraunhofer IPT has successfully developed noble glass coatings in several research projects.

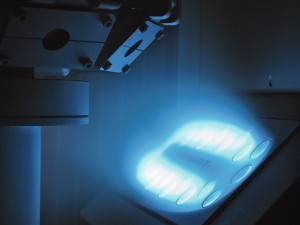

Interior view of the new diamond-like carbon coating system at the Fraunhofer IPT Metal and nitride hard coatings have been developed as protective coatings for various glass forming tools and brought to industrial application. Precious metal coatings, for example, are specially designed to extend the service life of forming tools for soda-lime glass, which is used as container glass and flat glass, among other things. Nitride hard materials, on the other hand, are very suitable for coating forming tools for chalcogenide glasses for infrared applications.

FCVA technology for smooth, defect-free coatings

Coated tools for forming complex optical glass components With the acquisition of the new diamond-like carbon coating system "FCVA Coating System LFFSI-6X" from the manufacturer NanoFilm Technologies International Ltd., the Fraunhofer IPT can now also offer coatings for other types of glass that are in industrial demand, such as fluorophosphate glass. The system uses the so-called FCVA technology (Filtered Cathodic Vacuum Arc), with which extremely smooth, defect-free coatings can be produced. These layers consist of carbon in a diamond structure and have particularly advantageous properties for glass forming, such as extreme hardness and maximum friction reduction. The very thin layers can also be used to coat tools for microstructured components. The FCVA technology for producing such high-purity coatings is now available for the first time at a European research facility. The functionality of the coatings is being investigated at the Fraunhofer IPT in publicly funded research projects and at the Aachen Center for Optics Production (ACOP).

Coated tools for forming complex optical glass components With the acquisition of the new diamond-like carbon coating system "FCVA Coating System LFFSI-6X" from the manufacturer NanoFilm Technologies International Ltd., the Fraunhofer IPT can now also offer coatings for other types of glass that are in industrial demand, such as fluorophosphate glass. The system uses the so-called FCVA technology (Filtered Cathodic Vacuum Arc), with which extremely smooth, defect-free coatings can be produced. These layers consist of carbon in a diamond structure and have particularly advantageous properties for glass forming, such as extreme hardness and maximum friction reduction. The very thin layers can also be used to coat tools for microstructured components. The FCVA technology for producing such high-purity coatings is now available for the first time at a European research facility. The functionality of the coatings is being investigated at the Fraunhofer IPT in publicly funded research projects and at the Aachen Center for Optics Production (ACOP).

The Fraunhofer IPT is now offering its project partners and the companies in the Aachen Center for Optics Production research work on the development of processes and process chains for precious metal and nitride hard coatings as well as DLC coatings. The portfolio of glass types that the Fraunhofer IPT can process in its in-house glass forming facilities ranges from chalcogenide glasses to soda-lime glasses and borosilicate glasses.