Rising energy and raw material prices make recycling, also known as "urban mining", not only profitable for a large number of used materials, but also an environmentally friendly process.

At the beginning of the recycling process, ferrous and non-ferrous metals as well as heavy non-metallic waste such as glass and wood are separatedSloganssuch as "For you it's waste, for us it's recyclable material", "We call it raw material" or "For a clean future" make it clear: the view of what people no longer want has changed. Whereas waste used to be incinerated almost without exception, people have become more aware and take a closer look today.

At the beginning of the recycling process, ferrous and non-ferrous metals as well as heavy non-metallic waste such as glass and wood are separatedSloganssuch as "For you it's waste, for us it's recyclable material", "We call it raw material" or "For a clean future" make it clear: the view of what people no longer want has changed. Whereas waste used to be incinerated almost without exception, people have become more aware and take a closer look today.

There is no doubt that the recycling industry is booming in western industrialized nations. An important player in Switzerland is Thommen AG, a family business founded by Gustav Thommen back in the 1930s. A descendant of the founder recognized the future of shredder technology, so he invested in the largest model with 2000 HP as early as 1972. The basic technical concept, which can still be seen today on the company premises in Kaiseraugst, also dates from that year. Since the commissioning of the plant, everything has been further improved and modified in detail at intervals of around 10 years. Gradually, suitable external companies were also taken over by Thommen AG and integrated into the group of companies.

Today, Thommen AG is a member of the group of companies with the brands Thommen, Metallum and Immark and employs around 550 people in Switzerland, who work at 15 locations. And they recycle several thousand tons of material every day. The Thommen shredder in Kaiseraugst, for example, produces up to 55 tons of Fe shredder scrap per hour. The company's core business includes the recycling of ferrous scrap, non-ferrous metals, electrical scrap and scrap car bodies and end-of-life vehicles, as well as individual recycling solutions for industry, commerce, municipalities and private individuals. The Group also operates internationally, which is why around 100 employees are based at 25 locations outside Switzerland. To give an order of magnitude: Metallum, which is part of Thommen AG, alone supplies around 3% of Chinese imports of non-ferrous metals.

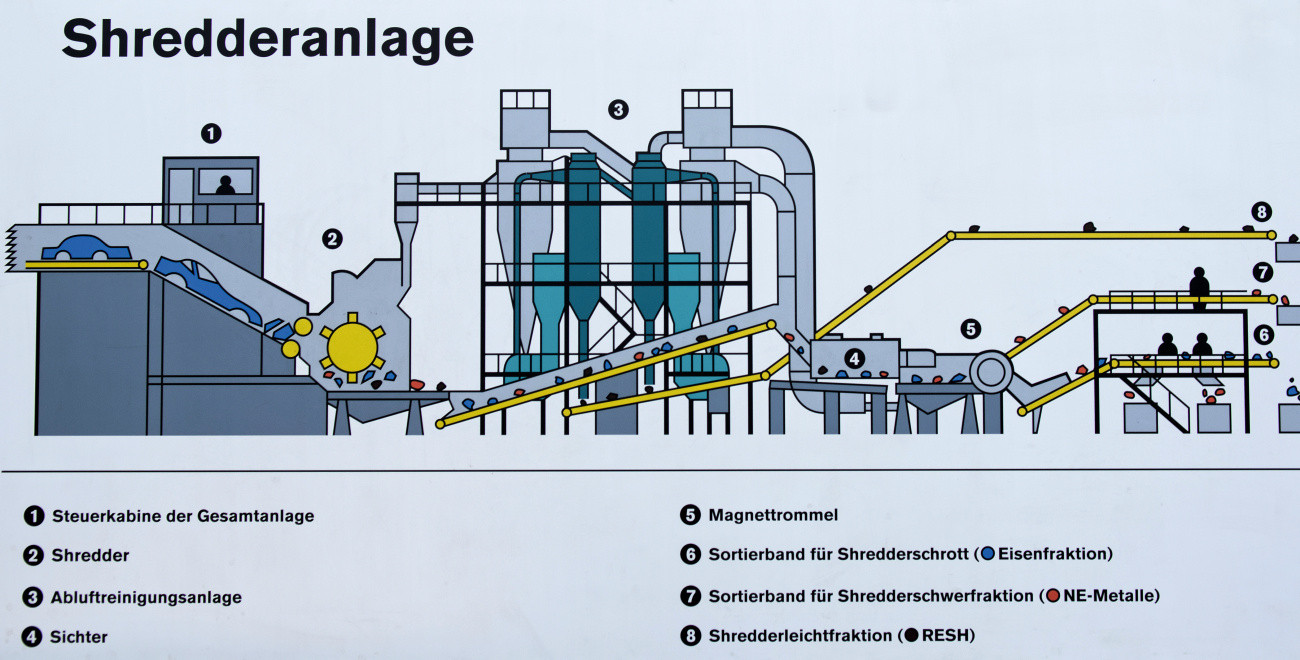

A graphic overview of the shredder system

A graphic overview of the shredder system

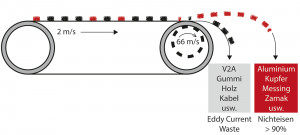

Schematic representation of the eddy current system. This separates non-metallic waste and non-ferrous metalsHans-PeterKremer is responsible for the entire shredder plant in Kaiseraugst, including the separation stages. The graduate engineer explains: "We are essentially dealing with three groups of materials. Ferrous metals are the largest group, accounting for 65%, but the proportion is continuously decreasing. The shredder light fraction accounts for 15 percent by weight. This mixture of waste has been recycled for energy in incineration plants in Switzerland and Germany since 2000. This group includes minerals, but also some plastics. The third group is made up of non-ferrous metals such as aluminum, zinc and copper, mixed with heavy waste materials (rubber, etc.). This fraction is called the shredder heavy fraction. It is first concentrated into a metal or waste fraction at the shredder and later refined into high-purity fractions somewhat away from the shredder.

Schematic representation of the eddy current system. This separates non-metallic waste and non-ferrous metalsHans-PeterKremer is responsible for the entire shredder plant in Kaiseraugst, including the separation stages. The graduate engineer explains: "We are essentially dealing with three groups of materials. Ferrous metals are the largest group, accounting for 65%, but the proportion is continuously decreasing. The shredder light fraction accounts for 15 percent by weight. This mixture of waste has been recycled for energy in incineration plants in Switzerland and Germany since 2000. This group includes minerals, but also some plastics. The third group is made up of non-ferrous metals such as aluminum, zinc and copper, mixed with heavy waste materials (rubber, etc.). This fraction is called the shredder heavy fraction. It is first concentrated into a metal or waste fraction at the shredder and later refined into high-purity fractions somewhat away from the shredder.

The recycling process always begins with the delivery of discarded products to the recycler. Thommen receives its input from waste disposal companies, car dealerships, farmers, the railroads and private individuals, for example. Kremer: "We receive household appliances, car wrecks, end-of-life vehicles, municipal scrap, railroad wagons and much more, and once we even received an airplane." It all arrives at the yard and is then first checked for foreign and contaminants and, if necessary, removed. After this preliminary work, the shredder input material is heaved onto the infeed plate conveyor in front of the shredder using huge excavators. The shredder shreds the input material into manageable pieces. After these steps, all the materials are still mixed together. After this material disintegration, separation takes place.

The XRT system at the front, the XRF system at the back

The XRT system at the front, the XRF system at the back

First, the shredded material passes through an air stream that extracts the lighter waste pieces at a rate of 65,000 cubic meters of air per hour. The magnetic shredder scrap is then separated using a huge magnetic drum (1.80 x 1.80 m). The special feature of this magnetic drum is that the polarity changes once when the iron parts are lifted out. This leads to a subsequent cleaning of the attracted magnetic material. The shredder scrap is immediately subjected to a final inspection and finally sold to steelworks at home and abroad.

INFO

The Thommen Group at a glance:

- Employees Switzerland: Approx. 550

- Employees worldwide: Around 650

- Locations in Switzerland: 15

- International locations: 25

- Business areas:

- Ferrous scrap, non-ferrous metals,

- electronics, waste disposal materials

- Turnover: Not disclosed

The final check is carried out by humansEverythingthat is not magnetic goes into the shredder heavy fraction. This fraction is screened online and then further separated on an eddy current sorting system (so-called non-ferrous separator). The operation of the non-ferrous separator is based on the induction principle. A rapidly rotating magnet system, which is mounted in a large deflection drum, induces a repulsive force on conductive parts. As a result, these parts detach from the conveyor belt and fly over a material divider. Non-conductors such as rubber, wood and plastics (but unfortunately also lead, copper cables and high-alloy steels) fall down in front of the material divider. The ratio of electrical conductivity to density acts as a separating feature in eddy current sorting. Therefore, aluminum with a factor of 13 can be separated very well on a non-ferrous separator, and stainless steel with a factor of 0 practically not.

The final check is carried out by humansEverythingthat is not magnetic goes into the shredder heavy fraction. This fraction is screened online and then further separated on an eddy current sorting system (so-called non-ferrous separator). The operation of the non-ferrous separator is based on the induction principle. A rapidly rotating magnet system, which is mounted in a large deflection drum, induces a repulsive force on conductive parts. As a result, these parts detach from the conveyor belt and fly over a material divider. Non-conductors such as rubber, wood and plastics (but unfortunately also lead, copper cables and high-alloy steels) fall down in front of the material divider. The ratio of electrical conductivity to density acts as a separating feature in eddy current sorting. Therefore, aluminum with a factor of 13 can be separated very well on a non-ferrous separator, and stainless steel with a factor of 0 practically not.

The metal and waste concentrate produced during eddy current sorting is further processed in Kaiseraugst in two special treatment plants. These are separate and are not linked to the shredder plant.

The plant for processing the waste concentrate has been in operation since 2010. High-purity stainless steel waste and residual metals are recovered in this plant. The stainless steel waste is sold to smelting plants. The same applies to blanks and Bei. Cable waste is granulated in-house. The waste produced (e.g. rubber) is used to generate energy.

The plant for separating metal concentrates from the Wibelstrom sorting process, which was inaugurated in 2021, is new in Kaiseraugst. This plant can be used universally and also processes third-party material. For this reason, a separate eddy current sorting plant, including a screening system, was built there. At the heart of the system are two multi-sensor sorting machines. In addition to the X-ray scanner, these machines, each two meters wide, are equipped with various other sensors. These detect shape/color, RGB light and near infrared.

The eddy current system in operationThefirst sensor sorting system is a so-called XRT separation unit. In this machine, the lumpy and monolayer non-ferrous parts are x-rayed and separated into two groups. The detected parts are discharged using compressed air pulses. This machine therefore separates light and heavy metals. Depending on the market influences, the light metal produced can be split again in a separate machine pass. This is done into an aluminum wrought and cast alloy. Due to the current high energy and raw material prices, these two aluminum qualities are in high demand from foundries. Before this plant was commissioned, the mixture of different aluminum alloys had to be sold to intermediaries. But that is now a thing of the past.

The eddy current system in operationThefirst sensor sorting system is a so-called XRT separation unit. In this machine, the lumpy and monolayer non-ferrous parts are x-rayed and separated into two groups. The detected parts are discharged using compressed air pulses. This machine therefore separates light and heavy metals. Depending on the market influences, the light metal produced can be split again in a separate machine pass. This is done into an aluminum wrought and cast alloy. Due to the current high energy and raw material prices, these two aluminum qualities are in high demand from foundries. Before this plant was commissioned, the mixture of different aluminum alloys had to be sold to intermediaries. But that is now a thing of the past.

The heavy metals such as copper, brass, zamak etc. can be fed to the second sensor sorting machine in batches or online. This uses the X-ray fluorescence process to separate the mixed heavy non-ferrous metals into material groups that can be melted down directly or into pure material fractions. Sorting is flexible and can be adapted to market demand.

In XRF sorting, the X-rays do not pass through the material. The back radiation from the uppermost metal layer varies depending on the material and can be used as a separation parameter.

The separation systems described above, which handle all of this, are quite enormous, so it is surprising that there are only a few people on the company premises. Kremer: "The separation process is almost fully automated. We can manage with 4 to 5 people." However, it is not possible to do without human judgment, especially in the final inspection. "The sensors can sometimes be fooled and the wrong metal ends up in the right batch - or vice versa. That's why, at the end of the process, people stand at the conveyor belt and sort out the proverbial rotten eggs," laughs Kremer.

The separated metals are then returned directly to the market. "One of our principles is that value creation must take place in-house," says Kremer. "We therefore sell directly to end customers without any intermediaries."

To summarize, several conclusions can be drawn. On the one hand, despite the simplicity of the processes, the recycling industry has also become a high-tech sector with complex technical equipment and process steps that require extensive expertise.

The entire separation plant for light/heavy metal separation was designed and installed by Mechanische Werkstätte Nützi GmbH. MWN focuses on customer-specific solutions in the recycling industry. Sorting machines from Steinert GmbH in Cologne are installed.

The recycling sector is also becoming increasingly important. Hans-Peter Kremer: "The more expensive and scarcer energy becomes and the more expensive and scarcer raw materials become, the more important the recovery of valuable materials becomes." And there is another winner - the earth. The extraction of mineral resources, i.e. primary raw materials, has in some cases become a very dirty business. Secondary raw materials from the urban mining mentioned at the beginning, on the other hand, protect people and the environment.

INFO

Balance sheet of horror

By 2050, the amount of waste generated worldwide in municipalities, industrial plants and private households will increase by around 70%, from two billion tons today to 3.4 billion tons. The World Bank recently warned of this.

The largest producer of waste is currently the USA with 624,700 tons per day. It is followed by China with 520,500 tons per day. In third place is Brazil (149,100 tons) and with 127,800 tons of waste per day, Germany occupies a dubious fifth place. In comparison, the recycling rate is rather poor: 30% in Europe, 25% in China and 9% in the USA. The waste that can neither be recycled nor landfilled is incinerated in waste incineration plants. This disposal method not only results in the loss of almost 95% of the raw material value, but also produces around 400 million tons ofCO2 worldwide every year.