The SAFETEC pump set from Sondermann Pumpen + Filter empties containers and drums filled with aggressive chemicals without employees coming into contact with hazardous substances.

To ensure that aggressive chemicals such as sulphuric acid or cleaning agents do not endanger people or the environment, they must be packaged safely. Drums or intermediate bulk containers (IBCs) are generally used for this purpose. They can be emptied safely via a permanently installed dip tube. With the SAFETEC pump set, Sondermann-Pumpen + Filter offers a self-priming system with a quick-release coupling for this purpose - guaranteeing that contact with the medium is ruled out.

Drums and IBCs in which aggressive and harmful chemicals are stored are usually emptied using drum pumps. However, there is a risk that an employee could pick up parts that are contaminated with chemicals, for example because they have to open caps or closures. New safety IBCs, on the other hand, are completely closed and sealed. This means that neither the contents can come into contact with dirt and foreign substances, nor can people come into contact with the hazardous liquids. In order to safely empty the contents of these containers, they are equipped with a dip tube. A quick-release coupling prevents the contents from escaping unintentionally. Sondermann Pumpen + Filter GmbH & Co KG, based in Cologne, has developed the SAFETEC pump set for this purpose, which empties the containers in a dosed manner using the suction method.

Hermetically sealed magnetic centrifugal pump

The core of the set is a self-priming magnetic centrifugal pump. The externally rotating drive magnet transmits the motor power to the internal magnet and thus to the impeller without contact. This means that a continuous shaft is not required and therefore no wear-inducing shaft seal to the motor. The pump chamber and drive are hermetically separated from each other by a containment shell. This prevents leaks. The pump is also maintenance-free. It is made from the main materials PP or ETFE. It has very good suction characteristics and runs smoothly and quietly. A sensor that monitors the leakage tray is available as an option. If a leak should nevertheless occur, for example at a screw connection, the pump switches off and the display shows the operator the fault.

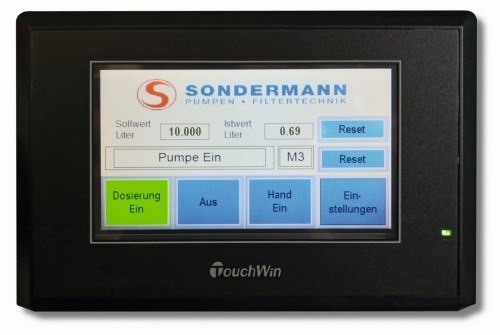

The operator can safely empty the container via the touch panel. Faults are displayed immediately

The operator can safely empty the container via the touch panel. Faults are displayed immediately

The pump set is available in a basic, a standard and two comfort versions. The Comfort D version, for example, includes a control point with a touch panel. Operating statuses and faults are displayed. There is also an emergency stop button and a main switch. When the tank is empty, the pump switches off automatically. Thanks to the integrated volume measurement and dosing electronics, the Comfort D version can also dose the medium into smaller containers. In automatic mode, various filling quantities can be stored and selected. When filling starts, the pump starts and stops automatically as soon as the desired filling quantity is reached. If the container is empty and the pump draws in air, it also switches off automatically. The graphic display on the touch panel shows the operating status. It can also be operated with gloves.

All components of the pump set, such as the pump, flow meter, sensors and control unit, are combined in a compact console. This is supplied with a wall bracket and can also be mounted on a trolley as an option.

Proven in practice

The SAFETEC pump set is the result of a collaboration with the Dutch manufacturer Promens, which developed the Varibox FC safety IBC. This double-walled container has no bottom outlet and can only be emptied using the suction method. The suction pipe is located at the lowest point of the IBC. The Varibox FC is used in combination with SAFETEC from Sondermann whenever hazardous chemicals are to be stored on a site or in a company without a WHG tank. Other applications include cleaning agents and disinfectants as well as car wash operators.

All photos: Sondermann Pumpen + Filter GmbH & Co KG