A piece of industrial history is disappearing: The Technical Center Surface (TZO) of Siemens AG Berlin is being dismantled to make way for a new district designed for sustainability.

Hustle and bustle in the temporary changing area. The personal protective equipment of the three teams of skilled workers and helpers is checked and replaced if necessary. Then a normal working day begins at the former Technical Center for Surfaces (TZO) of Siemens AG Berlin. "Quite normal" in this case means dismantling the contaminated galvanic systems, the associated operating units such as ventilation or water treatment systems and the network of pipelines for various hazardous substances.

Here it is the residual adhesions and undefined quantities of residual liquid in the pipes that make the dismantling work difficult. The labeled barrels for the fuming hydrochloric acid or the cyanide waste water are already ready. At the same time, the areas in which the installed mineral wool insulation materials are to be dismantled and packed dust-tight on site for safety reasons are being prepared. Two team leaders begin to go through the work packages and check the work materials already in use for possible damage caused by the hazardous substances present. At the same time, the appropriate waste containers are provided. This work step is accompanied by the external health and safety coordinator (SiGeKo) and the person responsible for contaminated areas. They have previously agreed the daily procedure with the site manager and instructed the teams accordingly. As already mentioned: business as usual on the "electroplating construction site".

Dismantling the over 30-year-old aluminum silver plating plant and corresponding cyanide exhaust air scrubber

In the neighboring hall, however, normal production operations at Switching Devices Berlin continue unabated.

But this construction site in the two halls and outbuildings covering approx. 5000m2 cannot be described as normal. The TZO is the electroplating facility operated by Siemens AG Berlin until September 2020. This electroplating plant was responsible for both internal and external customers and had a unique selling point worldwide due to its diverse, particularly cyanide processes. It was precisely these very specific cyanide processes that led to an incident classification in the upper class of the operating area in accordance with the Federal Immission Control Act (BImSchG). And it was precisely this classification as a hazardous incident - the other side of the coin, so to speak - that proved fatal for this successful electroplating plant. For Berlin and Siemens, an opportunity now presented itself for contemporary but above all sustainable urban development. The newly named "Siemensstadt Square" district is more than just an urban project. Rather, it is an opportunity to sustainably combine urban life, industrial progress and education under the roof of Siemens AG in the future.

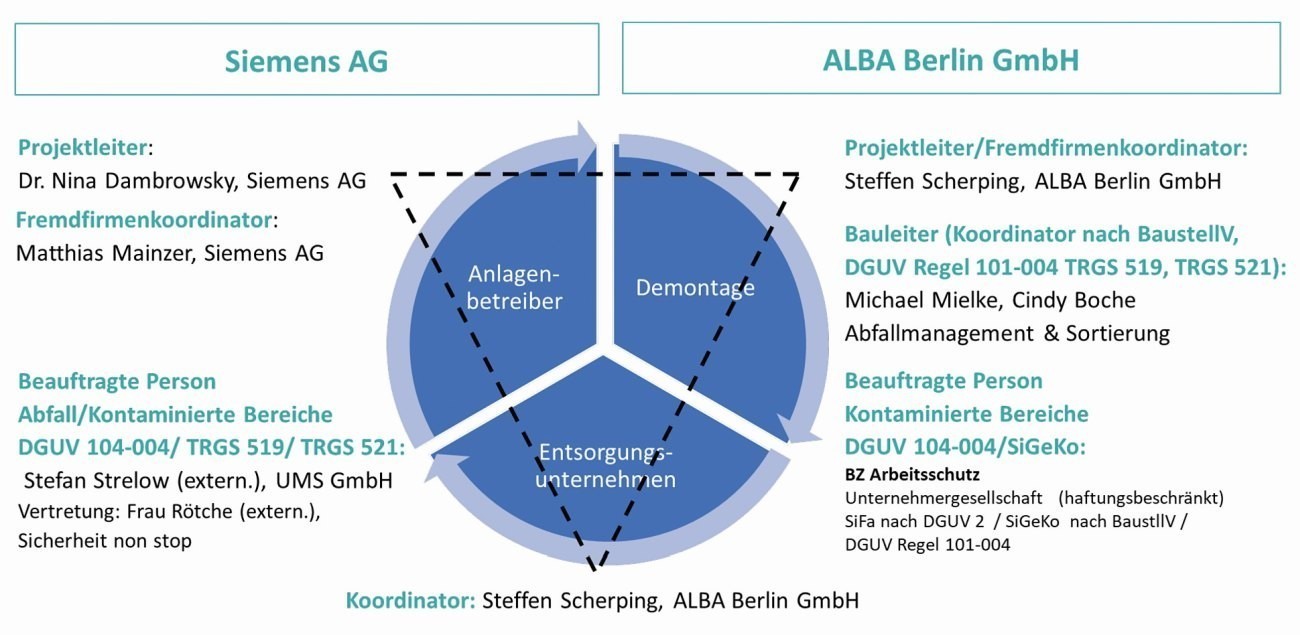

Project team of the Siemens AG electroplating dismantling project

Project team of the Siemens AG electroplating dismantling project

And all this on a historic industrial site that served as an industrial area for Siemens as early as 1897 - with a high level of manufacturing diversity and the corresponding vertical range of manufacture. This also included an electroplating process. The sustainable concept of open and progressive urban development is naturally opposed to such a disruptive operation, as it is necessarily highly regulated and therefore restricts development. In order not to stand in the way of a "Smart Campus of the future", it was decided with a heavy heart not to continue operating the electroplating plant.

UMS Strelow GmbH

Stefan Strelow, the company's CEO, has been contributing his expertise from 30 years of professional experience in the chemical and waste disposal industry to his company, UMS Umweltmanagement Strelow GmbH, for more than 10 years. His tasks include waste management, technical field service activities, such as the professional disposal of waste and hazardous substances, working in contaminated areas, dismantling industrial plants and transporting hazardous goods. In addition, the expertise as a waste officer, hazardous goods officer, immission control officer, asbestos officer and officer for contaminated areas. UMS Strelow GmbH is also committed to developing new recycling options for waste.

www.um-s.eu

The decommissioning of a hazardous incident plant or, in principle, a plant requiring a permit is regulated by law under the Federal Immission Control Act (BImSchG), which is intended to protect against harmful environmental impacts caused by air pollution, noise and vibrations. Decommissioning therefore means much more than just pulling the proverbial plug. The operator of installations requiring approval in accordance with BImSchG §5 (3) is obliged to decommission them in such a way that no harmful environmental effects, other hazards, significant disadvantages and nuisances for the general public and the neighborhood can be caused or emanate from the installation or the installation site even after it has ceased operation. This also means that the existing waste or waste resulting from the dismantling must be properly and harmlessly recycled or properly disposed of without impairing the general public's well-being.

One of the major challenges here is restoring the plant site to a proper condition, which requires particular care in planning due to the 70 years of use of the halls for galvanic processes and the associated complex pre- and post-treatments. Therefore, an investigation, including the history, was carried out in close coordination with the responsible authorities and correspondingly approved sampling of soil/soil air, groundwater and buildings in order to be able to reliably assess the contaminated sites and the resulting remediation measures.

INFO

Alba Berlin GmbH

The Alba Group is active in Germany, Europe and Asia as a recycling and environmental services provider and raw materials supplier. In 2019, its business divisions generated a turnover of 2.0 billion euros and employed a total of around 8,800 people. The portfolio also includes the dismantling of contaminated and non-contaminated industrial facilities. The dismantling of industrial facilities and the associated recycling activities of the Alba Group saved more than 4.2 million tons of greenhouse gases and 32.3 million tons of primary raw materials in 2019 alone.

www.alba.info

However, dismantling a long-standing electroplating plant with its cyanide-contaminated areas that has grown over several buildings, halls and their ancillary facilities is more than just a challenge. Meeting the complex tasks flexibly with suitable strategies became daily business and led to new insights. In particular, the different operating levels that follow on and above each other mix up the otherwise clear separation of cyanide and acid/alkaline areas during dismantling. The consideration of all risks in the areas of environment, health and safety led to the decision to form a team for the various responsibilities, which can advise the contractor, ALBA Berlin GmbH, as well as the client, Siemens AG, together or independently of each other. This meant that, on the one hand, the extensive experience in the dismantling of contaminated plants in accordance with DGUV 101-004, but also TRGS 524, TRGS 519 and TRGS 521 and, on the other hand, a 360° view with regard to the Occupational Health and Safety Act, the Recycling Management Act, the Hazardous Goods Ordinance, the Hazardous Substances Ordinance and the Workplace Ordinance meant that all aspects could be dealt with with the necessary care.

"We learned a lot and grew with this construction site, but we also grew together as a team. I could hardly sleep for the first few weeks and wondered whether we hadn't overestimated ourselves with this dismantling and the associated dangers," says Steffen Scherping, the project manager for the dismantling at Alba Berlin GmbH. Ultimately, however, he aptly describes the initial concerns, which were also reflected in the number of unsafe situations in the accident pyramid and repeatedly led to an adjustment in the risk assessment.

After just two months, a review of the first offer, including the planned work equipment and the personal protective equipment to be used, showed that the actual pollutant load/contamination exceeded the forecast.

INFO

Alba Berlin GmbH

The Alba Group is active in Germany, Europe and Asia as a recycling and environmental services provider and raw materials supplier. In 2019, its divisions generated a turnover of 2.0 billion euros and employed a total of around 8,800 people. The portfolio also includes the dismantling of contaminated and non-contaminated industrial facilities. The dismantling of industrial facilities and the associated recycling activities of the Alba Group saved more than 4.2 million tons of greenhouse gases and 32.3 million tons of primary raw materials in 2019 alone.

www.alba.info

Even the experience gained by Alba Berlin GmbH during the refurbishment of the burnt-down Hall 3a1 of the TZO in 2009 was only a fraction of the conditions that would result from a complete dismantling. Ensuring a controlled dismantling of the facilities without the occurrence of unwanted chemical reactions (hydrogen cyanide, nitrous gases, hydrogen sulphide) requires a very prudent approach. After all, the majority of the pipelines laid are 50 years old and over 70 meters long, laid above ground in bundles, with brittle weld seams and bent pipe sections full of residual liquids. And all of this was integrated into an existing infrastructure and media supply for the halls. Among other things, this meant welding the respective pipe sections daily at the end of the shift to prevent uncontrolled leakage of liquids or gases.

A lack of labeling and unclear routing of the pipes led to the separation of even active pipes with equally "active" irrigation of the affected areas - only quick and courageous intervention in the respective supplied areas prevented a further landfall. But as Michael Jenzik, Managing Director of Kunststofftechnik Jenzik and a valued supplier to Siemens for decades, commented: "The plants and operating units were built and modernized in such a way that safe operation was possible, but no attention was paid to the dismantling of the galvanic plants.

Dismantling of 20 meter long pipelines in the connecting corridor to the other factory halls of the Berlin switchgear plant, which, in addition to the risk of pipes running parallel to acid concentrates and cyanide wastewater, must also have decontaminated traffic and escape routes after the area has been decontaminated. Proof of pH neutrality of the various areas.

In the initial planning discussions, the small paint shop rebuilt in 1978 following the refurbishment of Hall 2a was not considered critical and was jokingly referred to as a "simple steel colossus". However, it proved to be a tough opponent during the actual work: numerous extensions and modernizations, several levels with insulation material without RAL quality marks, steel plates welded in five layers and covered with paint residue in some cases, huge amounts of paint dust in disused exhaust air ducts and enclosed chambers made life difficult for the work teams. Constantly extended risk assessments led to unforeseeable project delays. The occurrence of weakly bound asbestos-containing sealing cords in combination with the vast quantities of finely dispersed dust particles from the artificial mineral fibers also caused this simple steel colossus to mutate into the Achilles heel of the entire project.

INFO

Wüstoff electrical installation

The range of services offered by the 13-man company has grown steadily since 1997. In addition to installation and support in high-quality residential construction, residential construction for property management companies, commercial customers and private households, this ultimately includes the portfolio of the entire electrical engineering sector, as well as the decommissioning of electrical systems and operating units through to e-check data technology. The customer base includes private building owners as well as major customers (SAT 1, Deutscher Städtetag Berlin).

www.wues thoff-elektro.de

Another challenge arose when sampling the soil/ground air by drilling a core hole up to 4.50 meters deep. At the last drilling point in the hall, of all places, a medium-voltage cable was encountered at a depth of 2.5 meters. This resulted in many well-meaning calls from shut-down production facilities in connected halls. During the subsequent excavation and repair work, in addition to the highly volatile polycyclic aromatic hydrocarbons (PAHs), soil contaminated with mercury and cyanides (according to LAGA 20 z>2) was excavated in the former cyanide soil cup, which had to be subjected to physico-chemical treatment. This contamination dates back to the time before the hall was renovated in 1978, when mercury was used in a quick pickling process that was common at the time. This meant that, in addition to dismantling the hall, the excavation and backfilling of the earth shaft in a cyanide soil tray had to be coordinated and monitored. This created a separate construction site on the construction site, which had to cope with the PAHs and other chemical reactions that occurred when backfilling with adjacent, potentially contaminated soil.

Normally, special attention is paid to the chemical hazards in an accident site, but the electrical hazards are very high in an automated contract electroplating plant with a high throughput, due to the very high proportion of large fixed installations as well as moving machines, electrical equipment, cable harnesses and control cabinets. Since September 2020, special measures have prevented systems from being switched back on in order to demonstrably exclude the operation of the systems. In order to be able to safely de-energize the systems, the corresponding procedure had to be carefully planned in order to clearly separate the interfaces for the remaining hall supply. The hall power supply is also absolutely essential for the fire alarm and smoke extraction systems. Of course, site power generators can de-escalate one or two conflicts here. Only after the work areas have been approved and handed over by the electrician appointed by Siemens does the specialist company Wüsthoff Elektroinstallation proceed in accordance with the DIN VDE 0105 series of standards in order to be able to safely hand over the final dismantling up to the "stripping" to the company Cindy Boche. For Ralf Wüsthoff, the dismantling of the incident site is an exciting environment, in which the water-cooled rectifiers in particular left a lasting impression, as - not only - he had never seen them like this before despite decades of experience. Here, Cindy Boche's employees put his proper procedure to the test, as the rectifier room was accidentally flooded with the "highlight" cooling water during dismantling and no electrical event occurred despite the measured pH 9. This impressively demonstrates how important it is for the work area to be disconnected from the power supply by a qualified electrician.

INFO

Cindy Boche Waste management

Founded in 1992, Begus Umweltschutz GmbH is a specialist company that removes CFCs, PCBs and other harmful substances from household appliances, electrical appliances, TVs and refrigerators throughout Germany. The cooperation with Alba resulted in a new field of activity - waste management/contaminant clean-up. Cindy Boche Abfallmanagement is active on the market after the spin-off of the company branch in pollutant remediation and waste management with the proven technical and expert knowledge (DGUV Rule 101-004 TRGS 519, TRGS 521, TRGS 524).

As the saying goes, you grow with your tasks - and everyone involved in this project had to realize that. Full commitment was required both in terms of technical measures and work equipment, but also with regard to the handling of contaminated systems and the hazardous substances used. The aim was to hand over a "swept clean", i.e. decontaminated, pH-neutral hall to the owner. We are already much closer to achieving this goal, as eleven of the sixteen AwSV facilities requiring approval have already been decommissioned by TÜV Rheinland.