Zinc-nickel coatings are widely used due to their excellent anti-corrosion properties. It is crucial for the quality of these and other metallic coatings that the composition of the galvanic bath remains within a narrow tolerance window. This is the only way to achieve the desired coating properties. Inline measurement using X-ray fluorescence analysis is the ideal method for efficient bath monitoring and control.

Electroplating baths are subject to process-related fluctuations, which can have a considerable influence on the deposition behavior and the resulting coating thickness. In order to better control the deposition process and avoid excessive rejects, the bath solutions must be monitored regularly by analyzing the solution as frequently as possible. In the case of an electroplating bath with zinc-nickel solution, at least four zinc-nickel bath analyses per hour are desirable. To this end, the metal concentration of the bath has so far been checked manually in the company laboratory, for example using wet chemistry, atomic absorption spectrometry (AAS) or inductively coupled plasma optical emission spectrometry (ICP-OES).

X-ray fluorescence as a key technology for bath analysis

However, as these manual measurement methods are very time-consuming and cost-intensive, bath checks are usually only carried out once or twice a day, which means that the desired frequency cannot be achieved. Due to the time lag between sampling and testing, real-time bath control is also not possible. Automating the measurement not only makes the testing process significantly more efficient in many respects, but also ensures consistent product quality.

In principle, the chemical analysis processes can be automated. However, due to the high salt load and aggressiveness of the zinc-nickel baths, the X-ray fluorescence measurement method is the preferred method for automation, as it does not require any further sample preparation compared to the other methods.

Automated inline quality control for electrolyte solutions

The Helmut Fischer Group, the market-leading measurement technology specialist for coating thickness measurement and material analysis, has developed a solution to these challenges. In combination with the powerful and proven WinFTM software, the Fischerscope XAN Liquid Analyzer meets all the requirements for inline solution analysis of electroplating baths (Fig. 1).

Fig. 1: The Fischerscope XAN Liquid Analyzer

Fig. 1: The Fischerscope XAN Liquid Analyzer

The fully automated inline XRF measuring device analyzes the metal concentration of up to four electroplating baths continuously and with high precision. The measurement results are shown on the touch display and the entire measuring system is controlled centrally. Calibration is also fully automatic. The Fischerscope XAN Liquid Analyzer is not only suitable for monitoring zinc-nickel baths, but also for monitoring other electroplating baths made of zinc, nickel, gold, chromium, rhodium or palladium.

Low maintenance thanks to innovative measuring cell

The key component of the inline measuring device is the measuring cell. This is a robust flow cell that has been specially developed in-house for the temperatures, pH values, salt loads, solvents and particle loads typical of the process. Consisting of particularly hard-wearing materials, the measuring cell proves to be particularly durable.

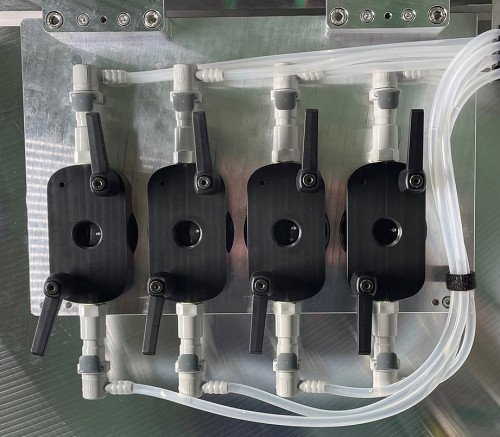

Fig. 2: Equipped with four measuring cells, each with separate inlets and outlets

Fig. 2: Equipped with four measuring cells, each with separate inlets and outlets

In a test setup under controlled laboratory conditions with a typical zinc-nickel solution, a measuring cell service life of over a year was achieved. However, the service life can vary as it depends, among other things, on the frequency of the rinsing and cleaning cycles, the composition of the coating baths and their temperatures as well as the ambient conditions(Fig. 2).

Equipped with four measuring cells, each with separate inlets and outlets

The standard equipment of the measuring device with four inline measuring cells and separate inlets and outlets means that a separate measuring cell is available for each electroplating bath to be monitored. This considerably simplifies the bath feed, eliminates the need for valves and prevents cross-contamination. In addition, the component materials for each channel can be specially adapted to the customer's electrolyte if required.

For smooth workflows in the production process

The Fischerscope XAN Liquid Analyzer is connected to the electroplating bath either directly via a bath pump on the device side or via a ring line on the customer side. As soon as the solution to be analyzed is fed to the flow-through measuring cell in the device, the metal content is checked fully automatically using X-ray fluorescence measurement. The measured values are displayed in real time on a screen (HMI) or exported directly to the higher-level control system via a fieldbus coupler. The special feature here is that the measurement data can be displayed simultaneously on other external monitors, e.g. directly at the electroplating bath. The operator of the system therefore always has the current measured values in view and can react quickly in the event of deviations, even if the measuring device is located in a separate room (Fig. 3).

Market-leading measurement performance

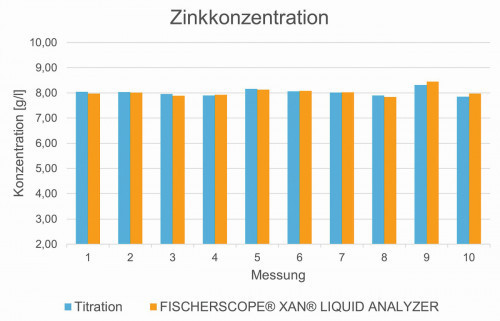

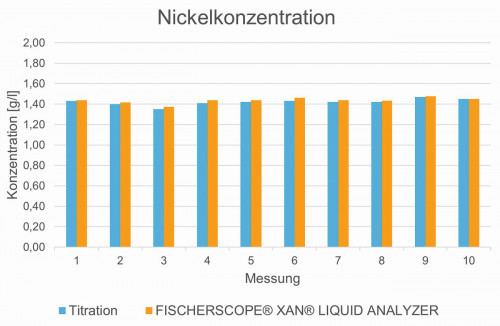

In order to compare an XRF measurement with a classic wet chemical analysis (titration), measurements were carried out on a typical zinc-nickel bath using both methods. A typical zinc-nickel bath consists of 5-15 g/L zinc and 0.5-2 g/L nickel. From 10 measurements carried out with the Fischerscope XAN Liquid Analyzer with a measurement time of 10 s each, the measurement results for the zinc concentration and the nickel concentration are shown in Figures 4 and 5.

The measurement results for the determination of the zinc and nickel concentration show close agreement with each other. The determination of the metal concentration of an electroplating bath using XRF measurement is therefore very comparable with titration in terms of measurement precision.

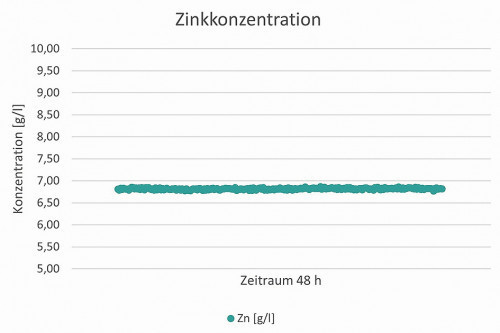

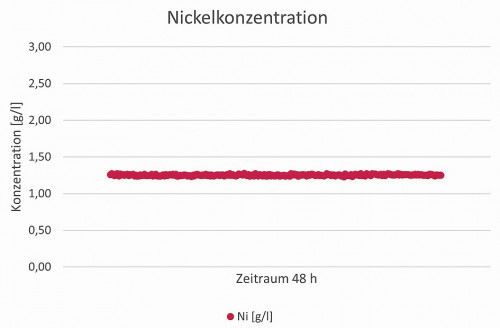

In order to further demonstrate the high-performance measuring behavior of the inline XRF measuring device, a further series of measurements was carried out on the zinc-nickel bath over a period of 48 hours using the Fischerscope XAN Liquid Analyzer. The measurement results are shown in Figures 6 and 7.

The results demonstrate that the new analyzer from Helmut Fischer delivers very good repeatability. With a measurement time of 10 s per measurement, an average value of 6.82 g/L was determined for the zinc concentration, with a coefficient of variation of only 0.26 %. For the nickel concentration, a mean value of 1.26 g/L and a coefficient of variation of 0.71 % were determined with a measurement time of 10 s per measurement. This means that the zinc-nickel bath is within the specified tolerances, as Table 1 also shows.

|

Zinc |

Nickel |

|

|

Mean value [g/L] |

6,82 |

1,26 |

|

Standard deviation [g/L] |

0,018 |

0,009 |

|

Coefficient of variation [%] |

0,26 |

0,71 |

The Fischerscope XAN Liquid Analyzer proves to be a well-suited solution for efficient inline monitoring of metal concentrations in electroplating baths. The XRF measuring device not only scores points with its very high measuring precision and repeatability of the measurement results. The fully automated and continuous analysis of up to four electroplating baths via four separate, durable measuring cells eliminates the need for time-consuming and cost-intensive manual spot checks. Measurement data is delivered in real time, making quality control in electroplating plants significantly faster and considerably more economical. This enables electroplating companies to ensure the consistently high quality of their electroplated coatings.