HISTORY[S] OF ELECTROPLATING

The development of electroplating along patent disputes

Significant scientific and technical developments have repeatedly resulted in major technological and social changes worldwide. Patents are of fundamental importance for the successful commercial exploitation of these cutting-edge achievements. Often, only a small circle of those directly affected learn what the enforcement and exploitation of patents means in practice. Examples such as the Ziegler catalyst [1] or Fischer-Tropsch [2] patents show how costly and difficult it is to successfully exploit even Nobel Prize-winning research results commercially. Disputes that often lasted decades, sometimes resembling a battle of "David" against "Goliath" and often resembling a crime novel in their historical course, show the perseverance and diplomatic skill that was and is sometimes necessary to help a new technology achieve broad-based success.

From around 1924, the impact of the electroplating of chromium on electroplating technology and its worldwide industrial and decorative use can hardly be overestimated.

Patent disputes characterize the early days

The development of electroplating can also be described in terms of patent disputes. Patent applicants and patent holders defended their submitted patents and blocking patents with the same tenacity with which they were attacked by outsiders, regardless of the justification for protection. Unlike the Ziegler catalysts or the Fischer-Tropsch process, the galvanochromium process, which was able to assert itself so suddenly and with such great force, was not the work of one inventor or one team of inventors. A long line of researchers and practitioners have contributed brick by brick to the success of industrially usable electroplating processes. Over a period of more than three quarters of a century, the work of individuals has led to the development of a practicable electroplating process [3]. Bunsen [4], Junot de Bussy [5], Geuther [6], Placet and Bonnet [7] developed the first electrolyte systems, but these were not used in practice anywhere. It was not until almost half a century after the first electrolytes based on chromic acid that Salzer [8] patented an electrolyte containing chromic acid and chromium oxide as well as an addition of chromium sulphate. In 1912, a patent was protected by Baum [9] which, in addition to chromic acid, also contained boric acid and chromium sulphate in a concentration corresponding to that used today. However, the chromium content was only one tenth of the values used today.

In Germany, Liebreich laid the decisive foundation for the commercial usability of chromium electrolytes between 1920 and 1924 with his patents for the electrolytic deposition of chromium.

From 1919, Liebreich turned his attention to electroplating and developed the fundamentals of chrome plating technology in 1920

Erik Liebreich, the son of a pharmacologist, had studied physics and chemistry in Berlin, Strasbourg and Munich, but also law, medicine and mechanical engineering. He eventually turned to chemistry and obtained his doctorate in 1910 at the Technical University of Charlottenburg. After completing his doctorate, he worked on corrosion issues. He developed anti-corrosion paints and founded Rostschutzfarbwerke Dr. Liebreich GmbH at Scharnweberstraße 128/129 in Berlin-Reinickendorf. In 1914, he published a monograph on the subject of rust and rust protection. From 1919, Liebreich turned his attention to electroplating and developed the basics of chrome plating technology in 1920. The classic chrome bath is based on his patent DRP 398 054 from 1920, which he subsequently developed further for Elektro-Chrom-Gesellschaft mbH Berlin. His patent DRP 448 526 from 1924 is regarded as the key patent for chrome plating. In 1923 Liebreich became a research assistant and in 1932 deputy head of the Department of Metal Chemistry and Metal Protection at the Chemisch-Technische Reichsanstalt in Berlin. At the same time, he taught electrochemistry as a private lecturer at the Technical University. In 1933, Liebreich was dismissed under the Law for the Restoration of the Professional Civil Service *) and moved into industry, including to Elektrochemische Werke Bitterfeld, Langbein-Pfanhauser Werke in Leipzig and Siemens & Halske in Berlin. After the Second World War, Liebreich returned to the Technische Hochschule Berlin [10].

Property right owners organize themselves in the C.I.G

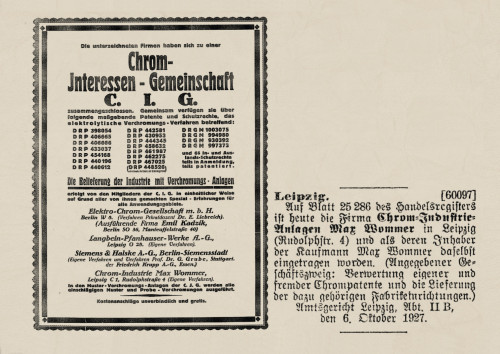

Fig. 1: Advertisement for the founding of the Chrom-Interessen-Gemeinschaft (C.I.G.) (Source: Galvanotechnik)As a result of numerous patent disputes relating to chromium electroplating, the Elektro-Chrom Gesellschaft founded the Chrom-Interessen-Gemeinschaft (C.I.G.) together with other property right owners in 1928. In addition to Elektro-Chrom Gesellschaft m.b.H. (Berlin), Langbein-Pfanhauser Werke AG (Leipzig), Siemens & Halske AG (Berlin) and the company Chrom-Industrie Max Wommer (Leipzig) were members of the Chrom-Interessen-Gemeinschaft (Fig. 1). The C.I.G. existed until it was dissolved by the Allies in 1945, with Max Wommer leaving just a few years after it was founded.

Fig. 1: Advertisement for the founding of the Chrom-Interessen-Gemeinschaft (C.I.G.) (Source: Galvanotechnik)As a result of numerous patent disputes relating to chromium electroplating, the Elektro-Chrom Gesellschaft founded the Chrom-Interessen-Gemeinschaft (C.I.G.) together with other property right owners in 1928. In addition to Elektro-Chrom Gesellschaft m.b.H. (Berlin), Langbein-Pfanhauser Werke AG (Leipzig), Siemens & Halske AG (Berlin) and the company Chrom-Industrie Max Wommer (Leipzig) were members of the Chrom-Interessen-Gemeinschaft (Fig. 1). The C.I.G. existed until it was dissolved by the Allies in 1945, with Max Wommer leaving just a few years after it was founded.

The main objectives of the interest group were

- To introduce the hard chrome plating process on as broad a basis as possible;

- to mutually exchange patents and property rights;

- to promote the process economically and practically and

- to jointly exploit the results obtained [11].

By 1932, there were already 1400 chrome plating plants in Germany

After the founding of the Chromium Interest Group, the economic importance of chrome plating technology increased sharply. In 1932, there were already 1400 chrome plating plants in Germany. The industrial property rights of this group of companies covered the entire field of chrome plating in its practical application.

With the economic importance that chrome plating seemed to be gaining at the end of the 1920s, the existence of companies outside the C.I.G. was threatened. Therefore, the companies Erich Kruppa and Dr. Oskar Hahn (Markranstädt) decided to file a nullity suit against Liebreich's key patent DRP 448 526 based on a publication by Sargent from 1920 [12]. The action was successful. However, the Reichsgericht overturned the judgment on appeal on the basis of an expert opinion by Fritz Förster. Fritz Förster was already a recognized figure in the field of electrochemistry at this time and is well known to experts for his standard work "Electrochemistry of aqueous solutions" [13].

In the meantime, chrome plating became increasingly important, so that customers of the plaintiffs against the Liebreich patent brought a series of infringement actions against the plaintiffs themselves, leaving them no choice but to file a new nullity action. Accordingly, this had to be supported with previously unused material. As no useful publications were known, success could only be hoped for by refuting Förster's expert opinion. However, no expert was found in Germany who was prepared to critically review Förster's report [14].

The companies Riedel & Co. and Friedrich Blasberg, with the support of the Verband der Deutschen Metallwaren-Industrie, had compiled extensive test material in their laboratories. Current density measurements at all possible temperatures, current densities, foreign acids and varying concentrations proved that the limit of 1.2 % sulphuric acid (in relation to chromic acid) specified in Liebreich's patent did not apply to this or any other foreign acids. The maximum current yield is 1.2 %, not the minimum. The nullity action filed by these companies against Liebreich's DRP 448 526 was declared null and void for the second time by the Nullity Senate of the Patent Office. At the same time, a further nullity action was filed against the so-called "nickel interlayer patent" DRP 440 612 of Siemens & Halske AG [14].

The patent law disputes, nullity and patent infringement suits dragged on for years. Taking into account the economic interests of the plaintiffs, they finally led to an expansion of the original C.I.G., which lasted until the end of the war.

This extended C.I.G. thus had a practically unlimited monopoly, as the German Reich Patent 448 526 had been reinstated by the appeal against the nullity judgment of the Reich Patent Office at the Reich Court, extending the scope of protection. Resourceful legal advisors had found a completely new interpretation by stating that Liebreich's patent was rightly valid and that the inventor had merely formulated his claim incorrectly, as would often happen. Liebreich had not meant to say that 1.2% foreign acid was the upper limit for the possibility of chromium deposition, but rather that he had found and meant that the chromic acid used to supplement the chromium baths could only contain up to 1.2% sulphuric acid if the chromium baths were not to accumulate sulphuric acid over time, which was not consumed, and thus become unusable.

The Reichsgericht accepted this interpretation. This meant that any use of technical chromic acid, which contains 0.2 % to 0.4 % sulphuric acid, to strengthen the baths was covered by the extended Liebreich patent [14].

Development in the USA

Fig. 2: A Buick X-Job, which was declared the car of the future in 1939. Buick had been part of General Motors (GM) since 1910. Chrome plating had already been used in the group and at GM subsidiaries since the 1920s, as the Buick X-Job shows (Photo: General Motors)Parallel to the history of galvanochromium plating in Germany, which was dominated by the Liebreich patents, galvanotechnical chrome plating, especially in the USA, also developed along the lines of disputes over chrome plating patents. Almost at the same time as the Liebreich patent applications, Prof. Colin G. Fink from Columbus University presented a chrome plating electrolyte, which he further developed together with his assistant Charles E. Eldridge between 1923 and 1925 on the basis of the Sargent electrolyte. They were only able to achieve consistent coating results when chemical manufacturers were able to supply chromic acid with a purity of < 0.1 % sulphate. Alongside Liebreich, Fink was the first to notice that the use of chromic acid without the addition of a catalyst did not enable sufficient chromium electroplating and who recognized the critical nature of the catalyst concentration. The first patent application by Fink and Eldridge was filed on August 26, 1924, but was later abandoned due to too many irrelevant details.

Fig. 2: A Buick X-Job, which was declared the car of the future in 1939. Buick had been part of General Motors (GM) since 1910. Chrome plating had already been used in the group and at GM subsidiaries since the 1920s, as the Buick X-Job shows (Photo: General Motors)Parallel to the history of galvanochromium plating in Germany, which was dominated by the Liebreich patents, galvanotechnical chrome plating, especially in the USA, also developed along the lines of disputes over chrome plating patents. Almost at the same time as the Liebreich patent applications, Prof. Colin G. Fink from Columbus University presented a chrome plating electrolyte, which he further developed together with his assistant Charles E. Eldridge between 1923 and 1925 on the basis of the Sargent electrolyte. They were only able to achieve consistent coating results when chemical manufacturers were able to supply chromic acid with a purity of < 0.1 % sulphate. Alongside Liebreich, Fink was the first to notice that the use of chromic acid without the addition of a catalyst did not enable sufficient chromium electroplating and who recognized the critical nature of the catalyst concentration. The first patent application by Fink and Eldridge was filed on August 26, 1924, but was later abandoned due to too many irrelevant details.

Along with Liebreich, Fink was the first to notice that the use of chromic acid without the addition of a catalyst did not enable sufficient chromium electroplating

In 1925, the Chemical Treatment Company started galvanic chromium plating. However, it was not until April 28, 1931 that the Chemical Treatment Company published the full details of the conditions under which bright chrome plating was possible and recorded in US patent application 1,802,463. This patent described the basic principles associated with chromium deposition and the need to maintain the ratio of chromic acid to sulfate ions at approximately 100:1. This patent specification also contained an explanation of the function of these ions and other radicals as catalysts.

With regard to the patent disputes, this is where Marvin J. Udy's patent, filed on June 17, 1924, comes into play, which made claims similar to those of Fink and thus triggered a patent dispute, which, however, came to a wise end with the plaintiffs' decision to join forces and form United Chromium Inc. to jointly exploit their patents [14]. United Chromium was later acquired by M&T Chemicals.

The litigation itself was a farce, however, as the courts could not agree and rendered contradictory decisions in favor of one plaintiff or the other. In the final decision, Udy's claim to be first inventor was upheld, but this was a Pyrrhic victory that benefited no one but the lawyers. United Chromium's subsequent attempts to collect license fees from countless alleged or actual patent infringers were an almost hopeless battle against overwhelming odds.

A major target of United Chromium's patent infringement suits was General Motors Corporation, which by this time had fully embraced chromium plating. To defend itself, General Motors applied for its own American patent on July 6, 1925, but it was rejected, even though French and British patents had been granted.

Chrome plating was then so widespread in Europe that it was practically impossible to collect license fees

In the meantime, chrome plating had become so widespread in Europe that it was practically impossible to collect license fees. Money was only made from the process through the

the sale of chemicals and materials, while license fees were of little or no consequence (15).

With this patent history in the background, the important galvanochrome industry developed in Germany, the USA and many other countries. One lesson that the patent history of electrochromium plating also holds is that with a large enough number of individuals and companies willing to ignore alleged or legitimate patent claims, owners of these rights can do little to enforce their claims.

*)The Law for the Restoration of the Professional Civil Service (BBG) was enacted after the National Socialists came to power on April 7, 1933. The title of the law was a misleading term. A professional civil service had already existed in Germany before.

The BBG served the purpose of removing Jews, people of Jewish origin and politically undesirable persons from the civil service (16).

Literature

[1] H. Martin: Polymers and Patents - Karl Ziegler, the Team, 1953 - 1998, Wiley-VCH Verlag GmbH, Weinheim, (2002)

[2] M. Rasch: History of the Kaiser Wilhelm Institute for Coal Research 1913-1943, VCH Verlagsgesellschaft, Weinheim, (1989), 178-208

[3] O. P. Krämer, R. Weiner, M. Fett: Die Geschichte der Galvanotechnik, Eugen G. Leuze Verlag, Saulgau, (1959)

[4] R. W. Bunsen: Poggend. Annalen 91 (1854), 619-625

[5] C. J. E. Junot: Engl. pat. 1183, 2812, (1852)

[6] A. Geuther: Liebig's Ann. 99 (1856) 314

[7] E. Placet: Comptes Rendus, 115 (1892) 945

[8] F. Salzer: DRP 221 472 (1907), DRP 225 769 (1909)

[9] M. Baum: EP 16865 (1912)

[10] Erik Liebreich: Wikipedia

[11]G. A. Lausmann, J. N. Unruh: Die galvanische Verchromung, Eugen G. Leuze Verlag (2006)

[12] G. Sargent: Trans. Electrochem. Soc. 17 (1920) 479

[13] F. Förster: Elektrochemie wässriger Lösungen, Verlag Johann Ambrosius Barth, Leipzig (1915)

[14] K. Gebauer: Die Entwicklung der Galvanotechnik in Deutschland in den vergangenen 50 Jahren; Galvanotechnik morgen - Bericht über die 10. Jahrestagung der Deutschen Gesellschaft für Galvanotechnik e. V. (DG) 29. September to 1. October 1971

[15] H. Silman: Chromium Plating - Past, Present and Future, Interfinish (1984) 140-146

[16] Law for the Restoration of the Professional Civil Service (BBG), Wikipedia