Wear protection

The presentation by Wadim Schulz from Aalen University focused on the influence of substrate engineering on tribological system properties. The protection of components against wear is typically achieved by applying hard coatings. The subsequent use is decisive for the selection of suitable coating systems. The lecturer, Prof. Joachim Albrecht and Florian Köhn from Aalen University, are currently investigating a different approach, namely influencing the tribological system properties of the substrate. The aim is to achieve specific effects during subsequent use. For example, mechanical structuring and/or laser treatment of the workpiece could be considered. Friction coefficients and wear volumes are to be controlled in an application-specific manner.

Dominik Höhlich (co-authors Luisa Schottstedt, Prof. Thomas Lampke) from Chemnitz University of Technology spoke about rust and acid-resistant iron-based alloys and REACh-compliant corrosion and wear protection. High-alloy steels such as 1.4301 (FeCr18Ni8) are used as bulk materials in applications that place high demands on corrosion and wear resistance. Due to their passivation, the metals chromium and nickel contained in this alloy enable the alloy itself to meet strict standards for nickel resistance and exhibit high wear resistance due to its low adhesive tendencies. The application of alloys with such a composition could considerably reduce the costs for applications in which stainless steel has previously been used as a solid material.

Jürgen Meyer presentation: Electroless nickel: replacement or supplement for chromium(VI) coatings?

Jürgen Meyer presentation: Electroless nickel: replacement or supplement for chromium(VI) coatings?

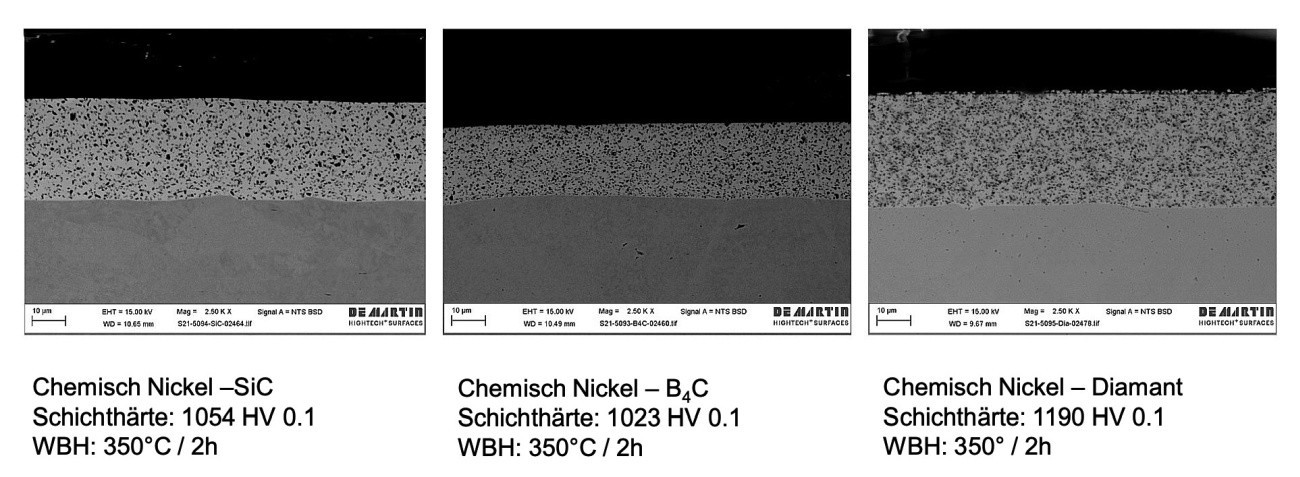

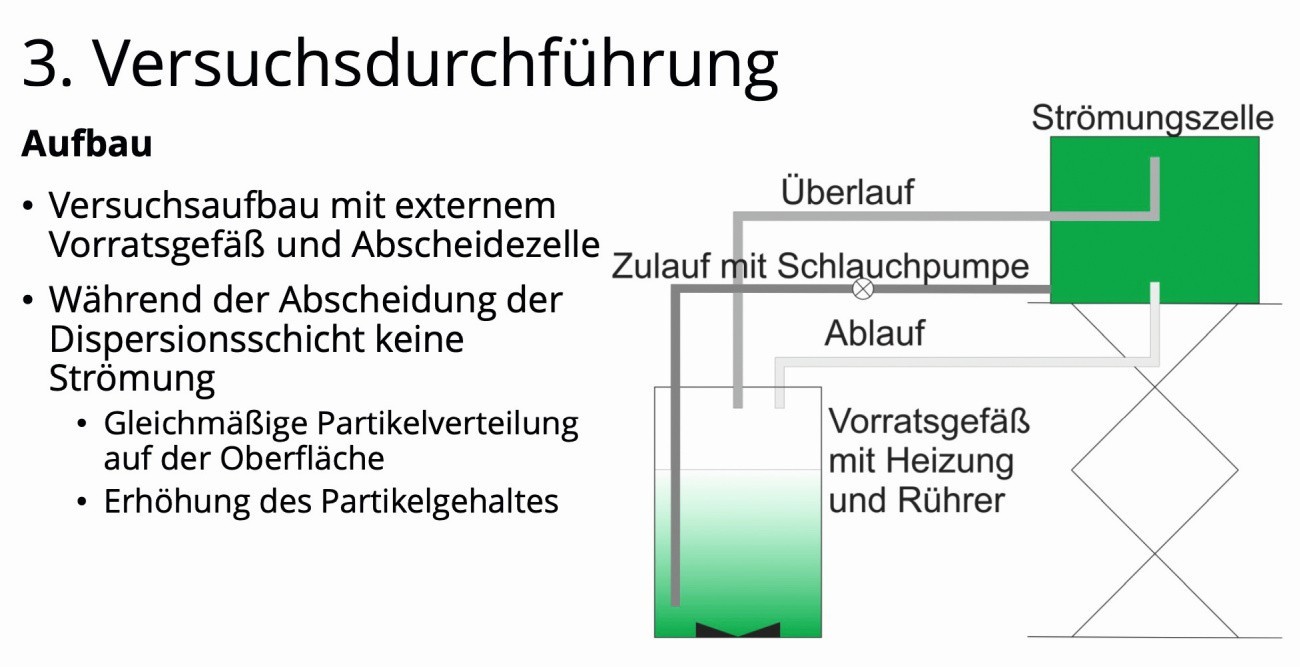

De Martin AG from Switzerland sent Jürgen Meyer to Berlin to talk about electroless nickel dispersion coatings. Meyer posed the question of whether these could be an alternative or a supplement to hard chromium coatings.

Hard chromium coatings have proven themselves in many applications for decades. Their advantages include high wear resistance, good friction properties, non-stick properties and, above all, the high cost-effectiveness of the process. However, REACh is now demanding that chromium(VI) coatings be replaced (soon). According to Jürgen Meyer, electroless nickel dispersion coatings are one way of solving this dilemma. Especially established dispersion layers with embedded particles in the micron size range unfold their full potential here.

Further application possibilities are now opening up through the use of new types of dispersion layers with significantly reduced particle sizes.

The presentation by Lars Lehmann from Chemnitz University of Technology dealt with the same topic: electroless nickel as a hard chrome substitute. Lehmann presented wear tests on heat-treated electroless nickel coatings and compared these results with hard chrome. The presentation showed the performance of electroless nickel coatings in various wear forms when they are used with optimum parameters such as phosphorus content, heat treatment temperature and time.

Functional coatings

Lecture Vogt: Coating alternative laser deposition weldingMartinLeimbach from Ilmenau Technical University spoke about the opportunities and challenges of electroless chromium deposition. The starting point was the current state of the art, in which chromium layers are deposited exclusively using galvanic processes. Their advantages are, for example, the high hardness of the layers, their high corrosion resistance and, of course, their attractive appearance. On the other hand, such electroplated coatings have a very low scattering ability and are therefore rather problematic when used on components with complex geometries.

Lecture Vogt: Coating alternative laser deposition weldingMartinLeimbach from Ilmenau Technical University spoke about the opportunities and challenges of electroless chromium deposition. The starting point was the current state of the art, in which chromium layers are deposited exclusively using galvanic processes. Their advantages are, for example, the high hardness of the layers, their high corrosion resistance and, of course, their attractive appearance. On the other hand, such electroplated coatings have a very low scattering ability and are therefore rather problematic when used on components with complex geometries.

An electroless process with chromium (III) compounds would be an elegant way of meeting the challenges described. This process avoids the disadvantages just described, but challenges users in other areas: complexing agents, reducing agents and process parameters must be coordinated in such a way that autocatalytic reduction to metallic chromium is possible. Determining factors are the slow kinetics of the chromium(III) complexes, the multi-stage reduction process and the accompanying development of hydrogen.

Laser cladding and high-speed laser cladding offer a technological, ecological and economical alternative to conventional coatings such as thermal spraying or chrome plating, says Dr. Sabrina Vogt from Trumpf Laser- und Systemtechnik. The main difference is that the laser beam melts the metal particles before they hit the workpiece and not just on its surface. This enables a very low heat input into the workpiece.

Dr. Vogt's lecture presented current results for various applications and gave an overview of new system technologies and processes.

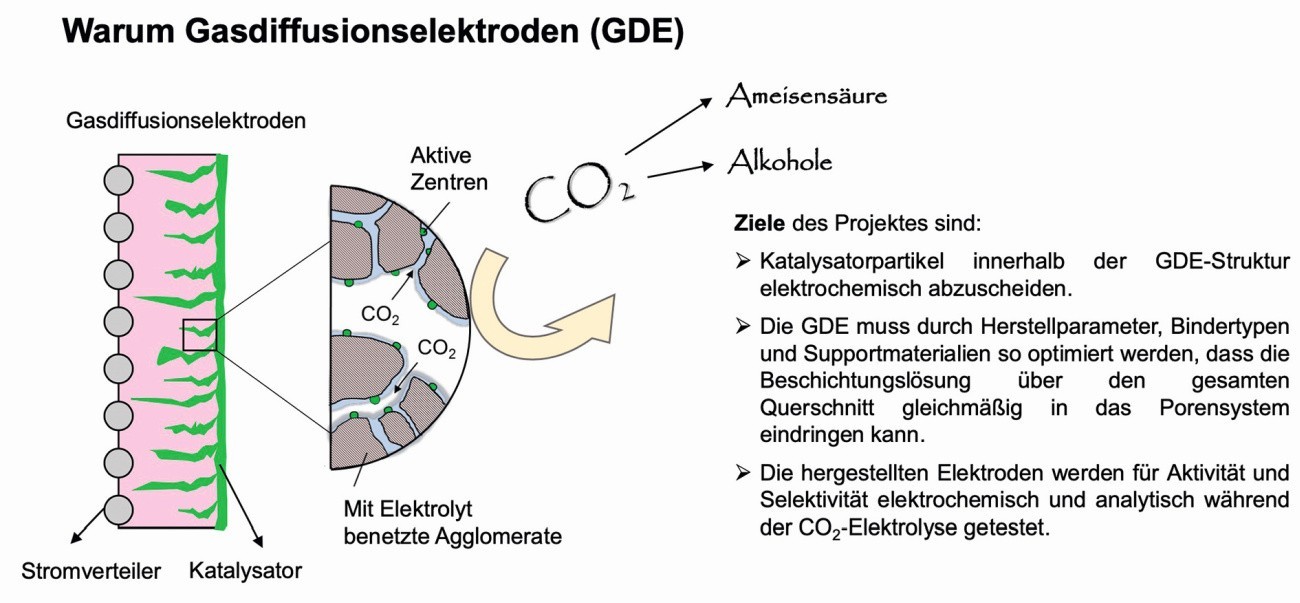

Dr. Mila Manolova (fem, Schwäbisch Gmünd) presented her investigations into the electrochemical deposition of tin, copper and bismuth on commercial and self-made gas diffusion electrodes (GDEn). Sn, Cu and Bi because they are inexpensive and have non-toxic properties. The background to these investigations is the "Green Deal" proclaimed in the EU, which envisages climate neutrality in Europe by 2050.

Presentation by Mila Manolowa: Gas diffusion electrodes

Presentation by Mila Manolowa: Gas diffusion electrodes

The lecture block on functional coatings was concluded with the topic of nickel-Ti-3SiC2 dispersion coatings for innovative material-locking connections using flip-chip thermocompression. The topic was presented by David Glück and Mathias Fritz from TU Ilmenau. Due to ever larger chip areas in optoelectronics, there is a major challenge to reliably join the contact points over the entire chip. This is why the market for flip-chip thermocompression bonding has developed at an above-average rate in recent years. The two speakers therefore created a flip-chip bondable metallization at the TU Ilmenau, in which electrically conductive hard material particles are incorporated. Electrically high conductivity and high hardness support the thermocompression process.

Presentation Glück/Fritz: Flip-chip thermocompression bonding

Presentation Glück/Fritz: Flip-chip thermocompression bonding